xjan99

Well-Known Member

Hi

Long story short - it will cost me roughly 2500 EUR to have these 3D scans made + to purchase the 3D files already done for sharing. Would there be interest in a "co-funding" approach to this?

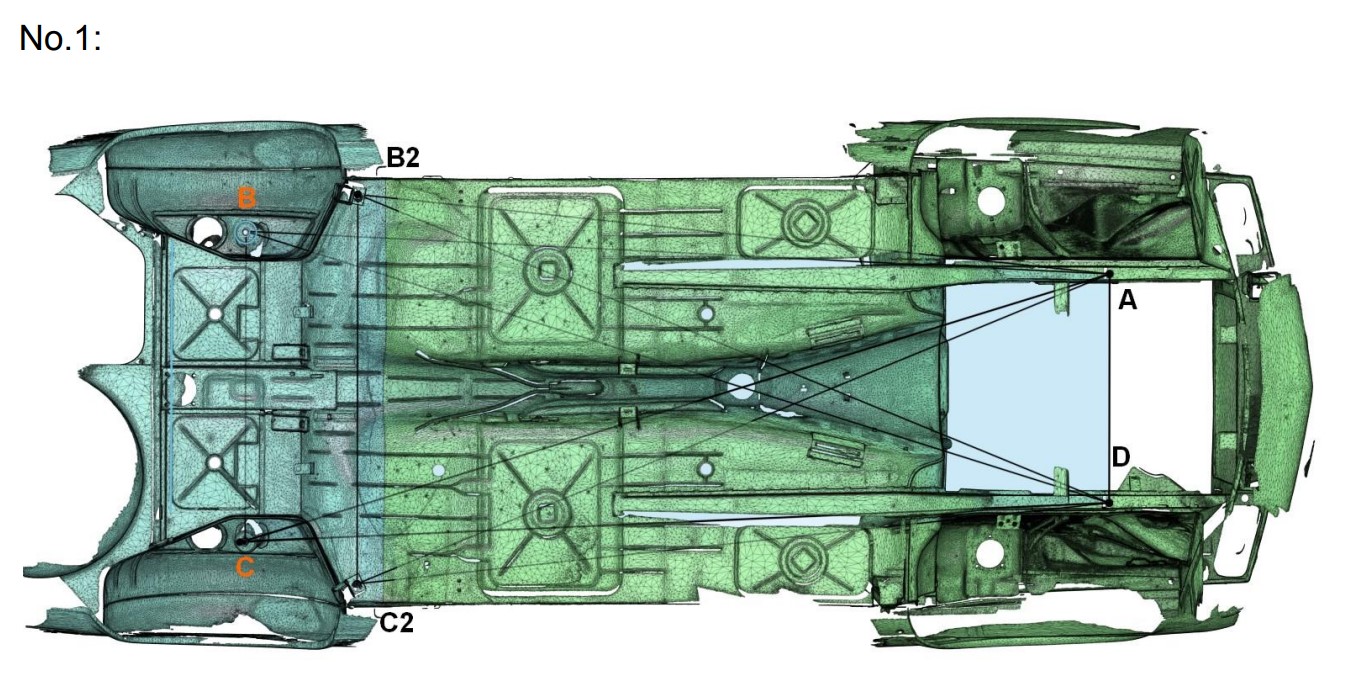

If you have seen my build thread, you have seen my coachbuilder made the 3D scans of a good E9 underside (and mine) + is now offering he can also 3D scan the OEM old-stock never installed front and rear fenders/panels + nose panel + tail panel and CSL apron I have. I am thinking this could be of use to many - either for reference measurements, 3D work mock-ups and even creating new products for these cars. Hell, some might even use these to start manufacturing new front fenders before BMW classic produces any . The scanner used is with a very high accuracy and outcome would be STL files (for Solidworks / Solid Edge / Fusion 360 etc programs).

. The scanner used is with a very high accuracy and outcome would be STL files (for Solidworks / Solid Edge / Fusion 360 etc programs).

I will start by throwing in 500EUR myself to support this, seems the community could benefit greatly. And if there are parts that you see should also be scanned, let me know.

PS! Also, there is a possibility to later produce some products by the same company (different materials 3D printed, moulds for carbon etc, laser cutting and bending...). They are working closely with https://www.kalmarautomotive.com/ (similar approach to Singer Porsches) and creating their parts for instance here in Estonia.

Long story short - it will cost me roughly 2500 EUR to have these 3D scans made + to purchase the 3D files already done for sharing. Would there be interest in a "co-funding" approach to this?

If you have seen my build thread, you have seen my coachbuilder made the 3D scans of a good E9 underside (and mine) + is now offering he can also 3D scan the OEM old-stock never installed front and rear fenders/panels + nose panel + tail panel and CSL apron I have. I am thinking this could be of use to many - either for reference measurements, 3D work mock-ups and even creating new products for these cars. Hell, some might even use these to start manufacturing new front fenders before BMW classic produces any

I will start by throwing in 500EUR myself to support this, seems the community could benefit greatly. And if there are parts that you see should also be scanned, let me know.

PS! Also, there is a possibility to later produce some products by the same company (different materials 3D printed, moulds for carbon etc, laser cutting and bending...). They are working closely with https://www.kalmarautomotive.com/ (similar approach to Singer Porsches) and creating their parts for instance here in Estonia.