I'm installing the differential, which seems as if it should be easy ("reverse of removal" as they say). It has not been.

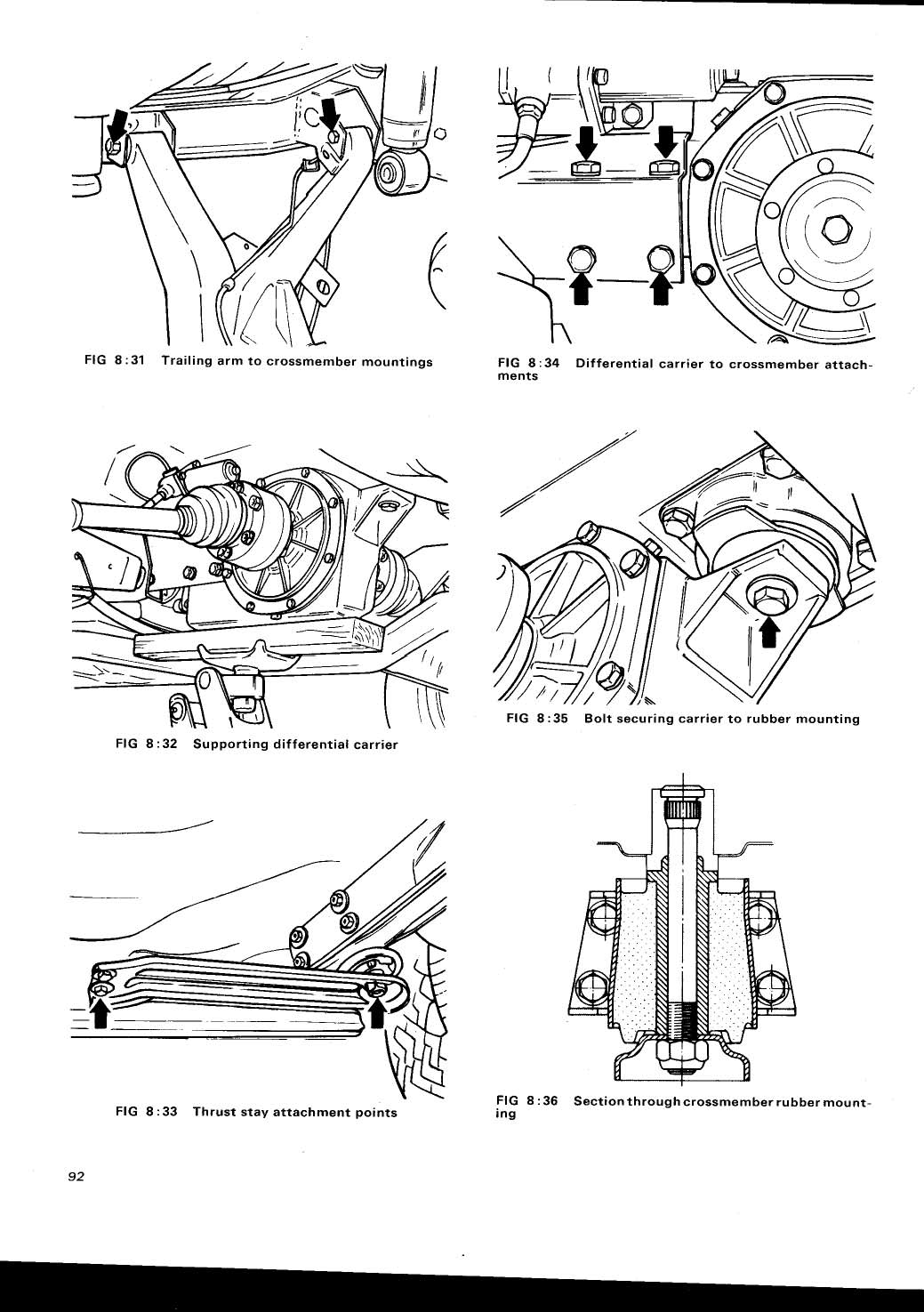

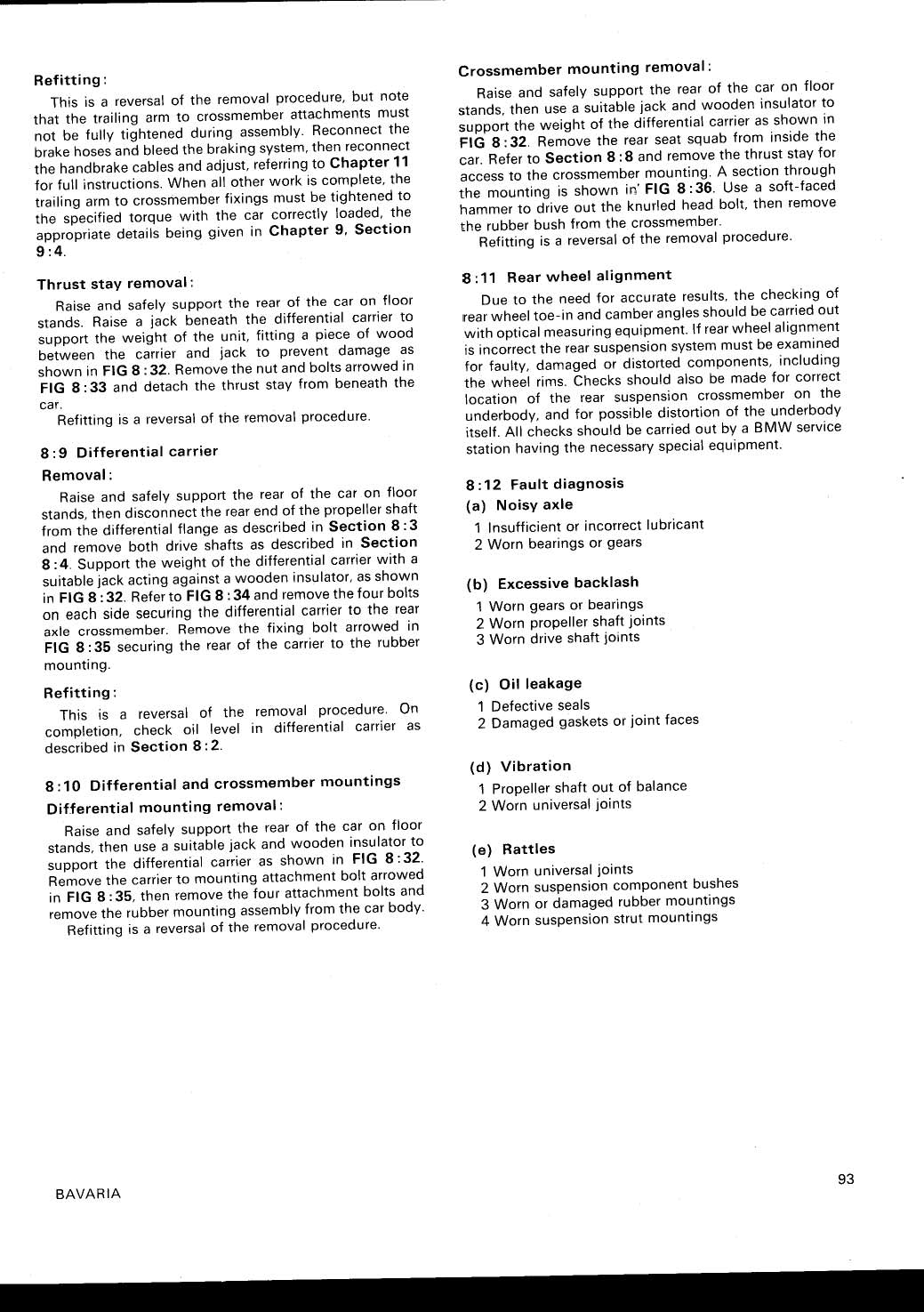

There are 8 bolts on the bracket (4 top, 2 on each side; 4 side, 2 on each side) and 1 bolt into the rear mount. The car is on jack stands and I'm working alone. I'm using a floor jack to support and maneuver the diff, with a secondary bottle jack on one end. I'm having a hard time lining things up, no matter what method I attempt or strategy I use.

Any tips from those who have done this would be appreciated. There must be some trick I have not yet discovered. Thanks.

There are 8 bolts on the bracket (4 top, 2 on each side; 4 side, 2 on each side) and 1 bolt into the rear mount. The car is on jack stands and I'm working alone. I'm using a floor jack to support and maneuver the diff, with a secondary bottle jack on one end. I'm having a hard time lining things up, no matter what method I attempt or strategy I use.

Any tips from those who have done this would be appreciated. There must be some trick I have not yet discovered. Thanks.