It seems that most of us with 38/38 or 32/36 Webers experience dry carb float bowls if our car sits for a relatively short period of time (>4 days?). I've put up with this for a year or two, but it's annoying and tough on the starter and battery and time to address the problem.

I've owned many collector cars with carburetors. Some had the same problem, some didn't. I could never figure out a common thread for those that did. New, rebuilt, old...it didn't seem to matter. Some did, some didn't. I could never pin down where the fuel was going. It couldn't be backing out of the carb up through the needle and seat. Liquids don't flow uphill. It couldn't be leaking externally out of the float bowl or there would be a gas smell and stains on the carb and manifold. It couldn't be leaking internally or the engine would be flooded on the first start attempt and the oil would be getting thinner and higher on the dipstick. The only thing that makes any sense is evaporation, but that sure seems like a stretch. There is only a pinhole size vent in the float bowl. It doesn't seem it could let that much vapor out. There is no gas smell in the garage. If anyone has a proven explanation why our Weber float bowls empty in 4 days I'd sure like to hear it.

I put an anti backflow valve in the fuel hose at the outlet of the tank. That didn't make any difference. I didn't expect it to. If the fuel in the line was draining back to the tank the float bowls should (theoretically) still be full and provide plenty of fuel to start and run the car until the pump filled the line again.

So now I'm ready to install an electric pump for the sole purpose of filling the float bowls prior to turning the key to start the car. I want to keep the mechanical pump as the primary. I think I've read all the threads here about this process. I want to put the electric pump next to the gas tank in the trunk. It might perform better if it was lower then the tank but I don't want to cut the hard line under the car and have the pump in a location that is difficult to get to.

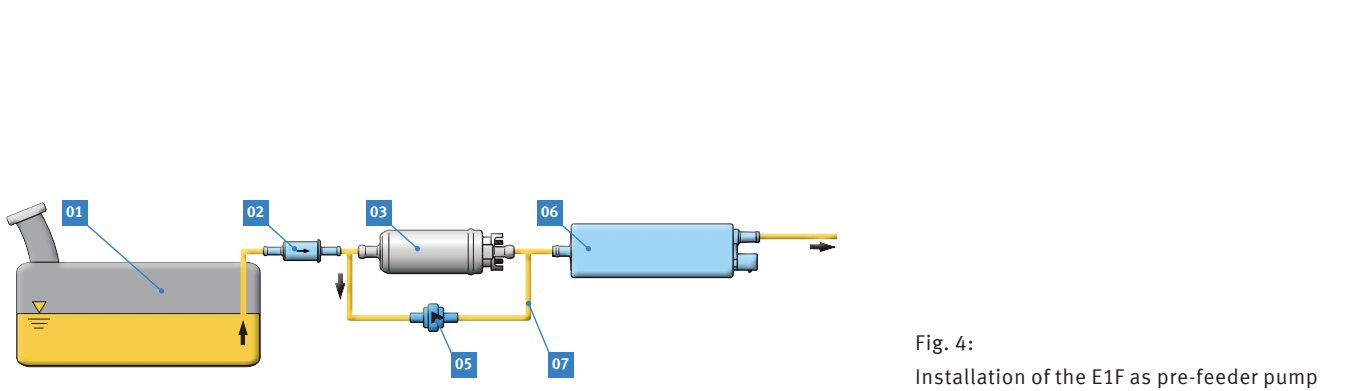

The Pierburg EF1 7.21440.51.2 seems to be the pump of choice here for my purpose. I found this diagram on the Pierburg site for what they call a "pre feeder pump".

03 is the pump, 02 is a coarse filter just to keep big junk out of the pump. They advise against a fine filter here because it could restrict the flow to the pump which would overheat the pump and burn it up. 05 is an anti backflow valve so that the output of the pump doesn't just go in a loop. 06 is an existing pump. In my case, the stock mechanical pump. The Pierburg is shown mounted above the fuel level which tells me it can "suck" fuel and would work in the application I'm considering.

How does this look to those that have installed an electric pump just to fill the float bowls prior to starting?

Does the fuel flow through the stock mechanical pump pre start OK?

What are some alternatives for mounting the switch/button to activate the pump?

I've owned many collector cars with carburetors. Some had the same problem, some didn't. I could never figure out a common thread for those that did. New, rebuilt, old...it didn't seem to matter. Some did, some didn't. I could never pin down where the fuel was going. It couldn't be backing out of the carb up through the needle and seat. Liquids don't flow uphill. It couldn't be leaking externally out of the float bowl or there would be a gas smell and stains on the carb and manifold. It couldn't be leaking internally or the engine would be flooded on the first start attempt and the oil would be getting thinner and higher on the dipstick. The only thing that makes any sense is evaporation, but that sure seems like a stretch. There is only a pinhole size vent in the float bowl. It doesn't seem it could let that much vapor out. There is no gas smell in the garage. If anyone has a proven explanation why our Weber float bowls empty in 4 days I'd sure like to hear it.

I put an anti backflow valve in the fuel hose at the outlet of the tank. That didn't make any difference. I didn't expect it to. If the fuel in the line was draining back to the tank the float bowls should (theoretically) still be full and provide plenty of fuel to start and run the car until the pump filled the line again.

So now I'm ready to install an electric pump for the sole purpose of filling the float bowls prior to turning the key to start the car. I want to keep the mechanical pump as the primary. I think I've read all the threads here about this process. I want to put the electric pump next to the gas tank in the trunk. It might perform better if it was lower then the tank but I don't want to cut the hard line under the car and have the pump in a location that is difficult to get to.

The Pierburg EF1 7.21440.51.2 seems to be the pump of choice here for my purpose. I found this diagram on the Pierburg site for what they call a "pre feeder pump".

03 is the pump, 02 is a coarse filter just to keep big junk out of the pump. They advise against a fine filter here because it could restrict the flow to the pump which would overheat the pump and burn it up. 05 is an anti backflow valve so that the output of the pump doesn't just go in a loop. 06 is an existing pump. In my case, the stock mechanical pump. The Pierburg is shown mounted above the fuel level which tells me it can "suck" fuel and would work in the application I'm considering.

How does this look to those that have installed an electric pump just to fill the float bowls prior to starting?

Does the fuel flow through the stock mechanical pump pre start OK?

What are some alternatives for mounting the switch/button to activate the pump?