Here's a problem I encountered that some others may find as well.

The crappy plastic fender grills.

When removed 3 years ago, the posts break off. BMW uses a rubber donut shapped washer that pushes on the post that goes through the metal fender and that holds the grill on the car.

So 2 relatively new grills were trash.

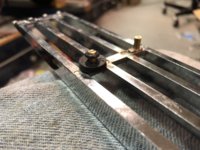

I thought about this and remembered my model train days when I would buy brass tubing from the hobby store. I had some around and was lucky I had the correct size to push on the posts and make them long enough to have some post on the inside of the fender to attach the rubber washers to. NOT, the BMW rubber washers have a spring steel disk inside them with the one-way teeth.

Push it on and it ain't coming off. That's why the posts break. I tried to drill the metal disk hole to a bigger size but the spring steel does not drill easily and the one way teeth catch on the drill bit and then it tares out of the rubber washer.

So once I got the brass rod on there, it was how was I going to hold them on. How about a washer and a tiny rubber o-ring. It took a good deal of effort to get this o-ring on the post so I am pretty confident it will stay. I will monitor after some miles.

I thought about putting threaded rod in the grills but was afraid they would break.

So here's a couple photos to explain this too complicated explanation. As a career photographer a photo is worth a 1000 words. Enough said.

The crappy plastic fender grills.

When removed 3 years ago, the posts break off. BMW uses a rubber donut shapped washer that pushes on the post that goes through the metal fender and that holds the grill on the car.

So 2 relatively new grills were trash.

I thought about this and remembered my model train days when I would buy brass tubing from the hobby store. I had some around and was lucky I had the correct size to push on the posts and make them long enough to have some post on the inside of the fender to attach the rubber washers to. NOT, the BMW rubber washers have a spring steel disk inside them with the one-way teeth.

Push it on and it ain't coming off. That's why the posts break. I tried to drill the metal disk hole to a bigger size but the spring steel does not drill easily and the one way teeth catch on the drill bit and then it tares out of the rubber washer.

So once I got the brass rod on there, it was how was I going to hold them on. How about a washer and a tiny rubber o-ring. It took a good deal of effort to get this o-ring on the post so I am pretty confident it will stay. I will monitor after some miles.

I thought about putting threaded rod in the grills but was afraid they would break.

So here's a couple photos to explain this too complicated explanation. As a career photographer a photo is worth a 1000 words. Enough said.