Had multiple things to do in the rear end so I decided it was time for a colonoscopy.

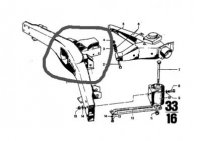

All new rubber bushings, brake backing plates, leak at input shaft of diff and new pads for springs. Powder coat all the pieces except diff.

This is a little tricky on a drive on lift.

All new rubber bushings, brake backing plates, leak at input shaft of diff and new pads for springs. Powder coat all the pieces except diff.

This is a little tricky on a drive on lift.