Sorry if this is a FAQ. From the factory the black wrinkle painted gauge bezels are crimped/(soldered)? to the mounting plate behind the wood. They have to be prised off in order to redo the wood. What is the best way to secure them back to the mounting plate again? I seem to recall someone using an epoxy but thought I'd ask for opinions...

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best method of securing gauge bezels

- Thread starter jefflit

- Start date

I used a dab of crazy glue along the back lip, enough to hold in place and not move when swiped to be clean, but just a drop or two.

...and to add to bavbob's excellent technique, I tend to use the gel variety of super glue, as it's a little easier to work with/control.

They are originally soldered in place. Super glue will do, but not sure if it will hold ten +years. Would the black type of glazing glue not work better? It is a bit less brittle.

Last edited:

I would also think black silicone caulk could work but I have sworn off the stuff, it is impossible to remove. I wondered about 3M strip caulk which I love because it is totally reversible.

A short attempt to do a @Markos on gauge cluster refurb:

Skipping the disassembly portion because I did that > 1 year ago. If I recall, separating the bezels from the instrument panel wasn't that difficult but it would appear from some leftover JB weld that a PO had already been in there once. Just be careful -- you want to keep the tolerances between the bezels and the panel tight and unbent. Once apart, wood went to Bela.

I'm not sure what others do to touch up the finish on the bezels but mine were in fine condition, maybe just a touch ashy, so I masked to the original mask lines and shot with a light dusting of rattle can semi-gloss engine enamel. I used a razor blade to remove the cardboard rings around the holes and to scrape off most of the previous adhesive (I did more cleanup after the photos).

Some PO had obviously used Permatex to glue the cardboard rings so they did not come off clean and I had to figure out a new solution. Given that every problem looks like a print to a man with a 3D printer, I measured the old ones and designed some new ones (2mm thick; 100mm ID, 108mm OD for the large holes; 87mm ID, 95mm OD for the small holes). My first print was in prototype orange PLA but you could see the orange around the gauges when installed and they didn't have any "give" to them so I reprinted in clear flexible TPU (Shore hardness 95 A). Those work perfect.

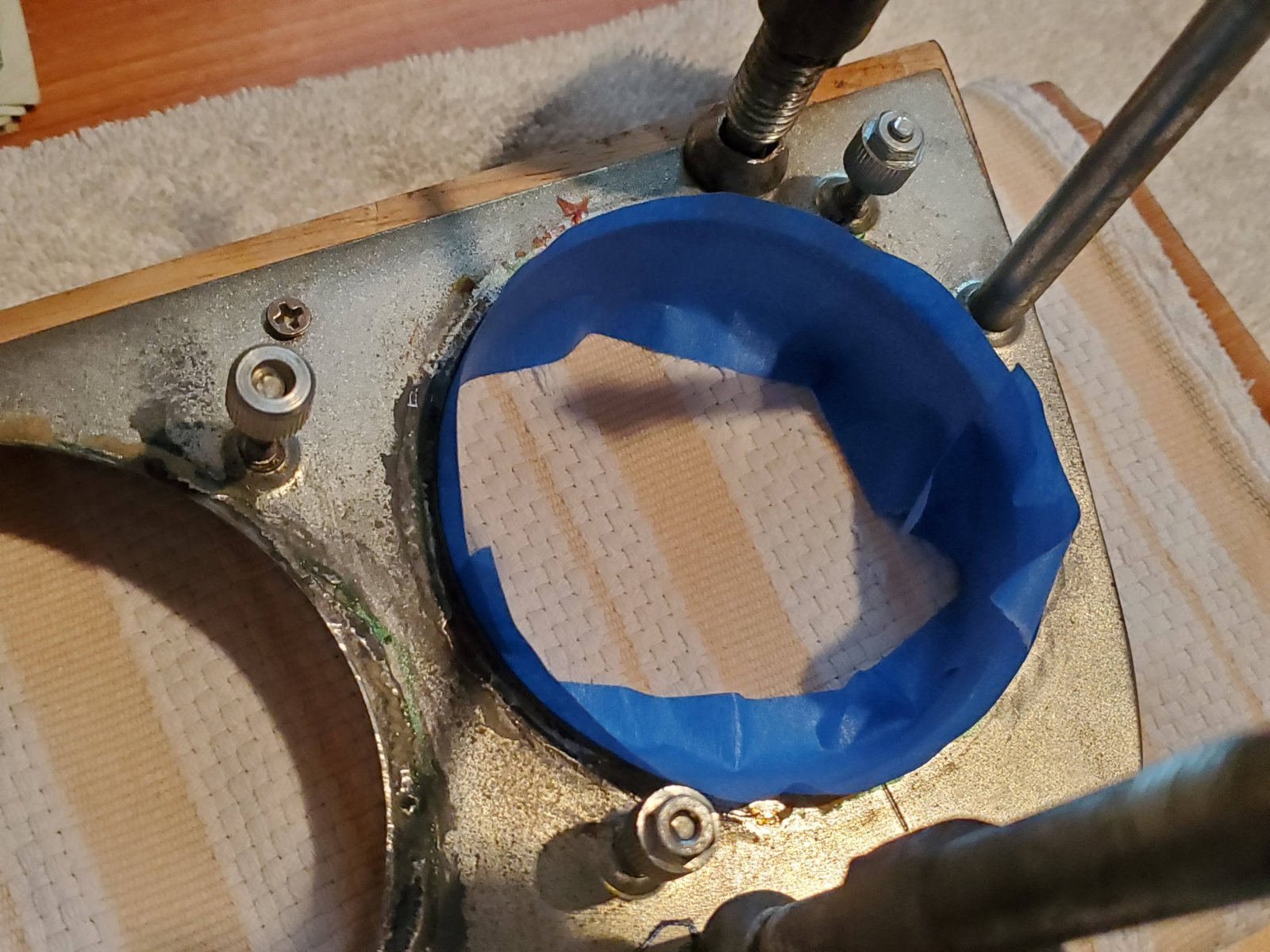

For assembly, I found a piece of wood a bit larger than the cluster, along with a couple clamps, and put down some towels. At first it seemed hit-and-miss as to how to assure I had the bezels properly rotated but then I noticed that there are scribe marks on both the bezels and the dash metal. This makes it idiot-proof for alignment. Take your time to make sure you've popped the bezel in all the way around -- the edge should protrude about 1/2mm all the way around. They should fit quite snuggly even without any adhesive. I decided to do one at a time for simplicity. Once seated properly, I clamped it into place using the scrap wood, with towel between.

I decided on CA glue but I didn't want to get any on the visible portion of the bezels so I taped off the inside. I used a toothpick to run the glue into the edge where the bezel and panel meet. I did about 12 drops all around the perimeter. Because I'm impatient, I sprayed some CA accelerant on a q-tip and wiped it around to cure the glue. When the tape was removed I had a couple spots where the glue climbed the tape above the level of the bezel but the razor blade knocked those off easily enough.

Unclamp, and repeat 3 more times. I haven't glued the rings down yet, as I am still working on gauges but I've test fit and a few dabs of CA glue will do the trick.

Skipping the disassembly portion because I did that > 1 year ago. If I recall, separating the bezels from the instrument panel wasn't that difficult but it would appear from some leftover JB weld that a PO had already been in there once. Just be careful -- you want to keep the tolerances between the bezels and the panel tight and unbent. Once apart, wood went to Bela.

I'm not sure what others do to touch up the finish on the bezels but mine were in fine condition, maybe just a touch ashy, so I masked to the original mask lines and shot with a light dusting of rattle can semi-gloss engine enamel. I used a razor blade to remove the cardboard rings around the holes and to scrape off most of the previous adhesive (I did more cleanup after the photos).

Some PO had obviously used Permatex to glue the cardboard rings so they did not come off clean and I had to figure out a new solution. Given that every problem looks like a print to a man with a 3D printer, I measured the old ones and designed some new ones (2mm thick; 100mm ID, 108mm OD for the large holes; 87mm ID, 95mm OD for the small holes). My first print was in prototype orange PLA but you could see the orange around the gauges when installed and they didn't have any "give" to them so I reprinted in clear flexible TPU (Shore hardness 95 A). Those work perfect.

For assembly, I found a piece of wood a bit larger than the cluster, along with a couple clamps, and put down some towels. At first it seemed hit-and-miss as to how to assure I had the bezels properly rotated but then I noticed that there are scribe marks on both the bezels and the dash metal. This makes it idiot-proof for alignment. Take your time to make sure you've popped the bezel in all the way around -- the edge should protrude about 1/2mm all the way around. They should fit quite snuggly even without any adhesive. I decided to do one at a time for simplicity. Once seated properly, I clamped it into place using the scrap wood, with towel between.

I decided on CA glue but I didn't want to get any on the visible portion of the bezels so I taped off the inside. I used a toothpick to run the glue into the edge where the bezel and panel meet. I did about 12 drops all around the perimeter. Because I'm impatient, I sprayed some CA accelerant on a q-tip and wiped it around to cure the glue. When the tape was removed I had a couple spots where the glue climbed the tape above the level of the bezel but the razor blade knocked those off easily enough.

Unclamp, and repeat 3 more times. I haven't glued the rings down yet, as I am still working on gauges but I've test fit and a few dabs of CA glue will do the trick.

Great step by step. Thanks Jeff!

I used dabs of epoxy, I would be afraid super glue would run or not fill in enough

we soldered mine back in place - took a couple of minutes ... just a tack or two per bezel. the bezels stick a little past the metal plate and allows you to put the tacks on the back side

I am missing the point on these virtuous elaborate ways of re-attaching the bezzels to the metal back plate

bezzels were originally soldered, yes

but you have to separate if you want to repair the wood,

question is why do you need to re-attach metal to metal

IMHO, it is enough to put a dab of silicone or PU mastik to secure the bezzels to the wood

maybe I am missing something ?

bezzels were originally soldered, yes

but you have to separate if you want to repair the wood,

question is why do you need to re-attach metal to metal

IMHO, it is enough to put a dab of silicone or PU mastik to secure the bezzels to the wood

maybe I am missing something ?

No. You're right. In fact, on a second car I am working on, the wood veneer was a tad thicker, just enough that there was less bezel lip coming through the backing plate, making the glue lip to plate method insufficient. I used some expoxy on the inner beveled wood surface to good result. You need to use an adhesive with some volume, as the bezels are not in direct contact. I pity the next person who tries to take them apart but it holds.

Marc-M

Well-Known Member

My black ones were bad - they had some sort of sticky pad on the inside but had lost its tack.

I re crackeled mine and used black 3m winscreen sealant ( the one that is non setting - bit bit runny when new but frims up aftera few days)

The 3 m stuff allowed me to rotate the bezle to seat propley and holds them in very well without rattle - but gives me the option if i need to take them out again.

Hope it helps

Marc

I re crackeled mine and used black 3m winscreen sealant ( the one that is non setting - bit bit runny when new but frims up aftera few days)

The 3 m stuff allowed me to rotate the bezle to seat propley and holds them in very well without rattle - but gives me the option if i need to take them out again.

Hope it helps

Marc