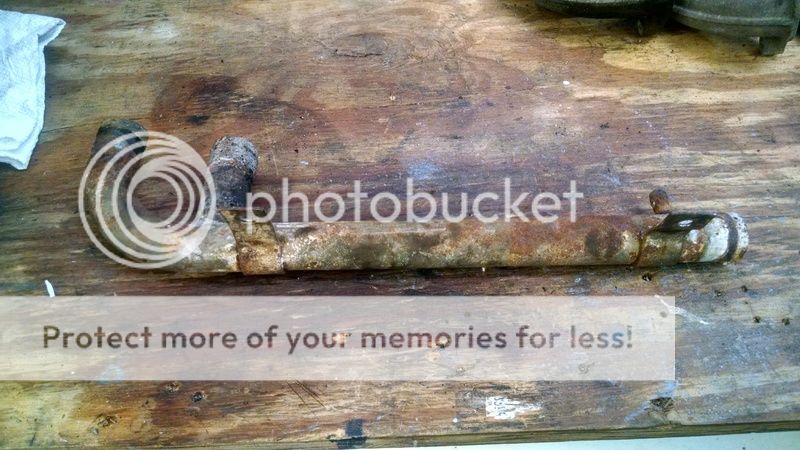

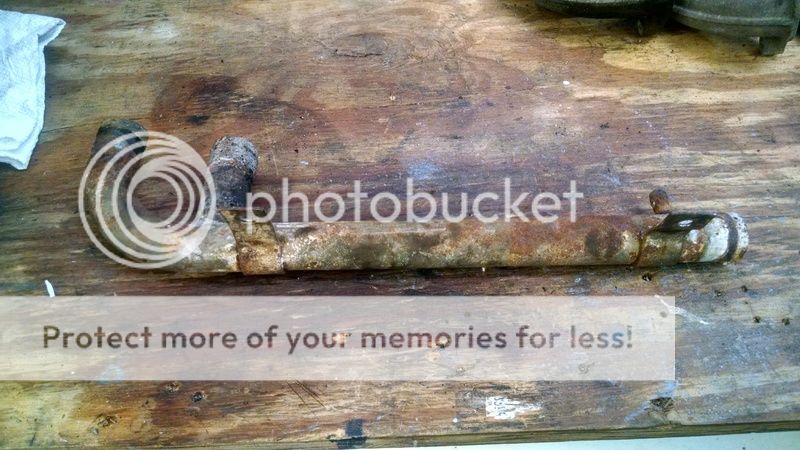

the easy DIY: as you are sending it out for plating, it isn't that crucial to get ALL rust off.

Best results: Clean it with a angle grinder with flap disc or wire wheel. Use a vise or you'll end up with stitches (AMHIK) Even an hand brush or sand paper can be good enough.

Priority is to get the flaky stuff off and get a mostly shiny surface. If its pitted then you will likely want to make it a smooth surface using a angle grinder with flap disc (60 grit for getting rid of rust, for shiny choose 200 grit flap discs).

As you are sending it out for zinc plating, you're OK to leave some tiny spots of rust in pits, corners etc. In the plating they dip it firstly in severe acids. That will remove all rust molecules, even in places that you wont reach with an angle grinder and a flap disc.

I see also some small clips for sheet metal screws, ideally take them of and sandblast them, then tie them with a steel wire to a big part. hand it all over to the plater, and you will get everyting back shiny and looking brand new.

Fyi, the inside of the tube will hardly get any coating due to the limitations of the plating process, the current doesnt "enter into" the pipe, giving no zinc deposit on the inside.

Erik