Bwana

Well-Known Member

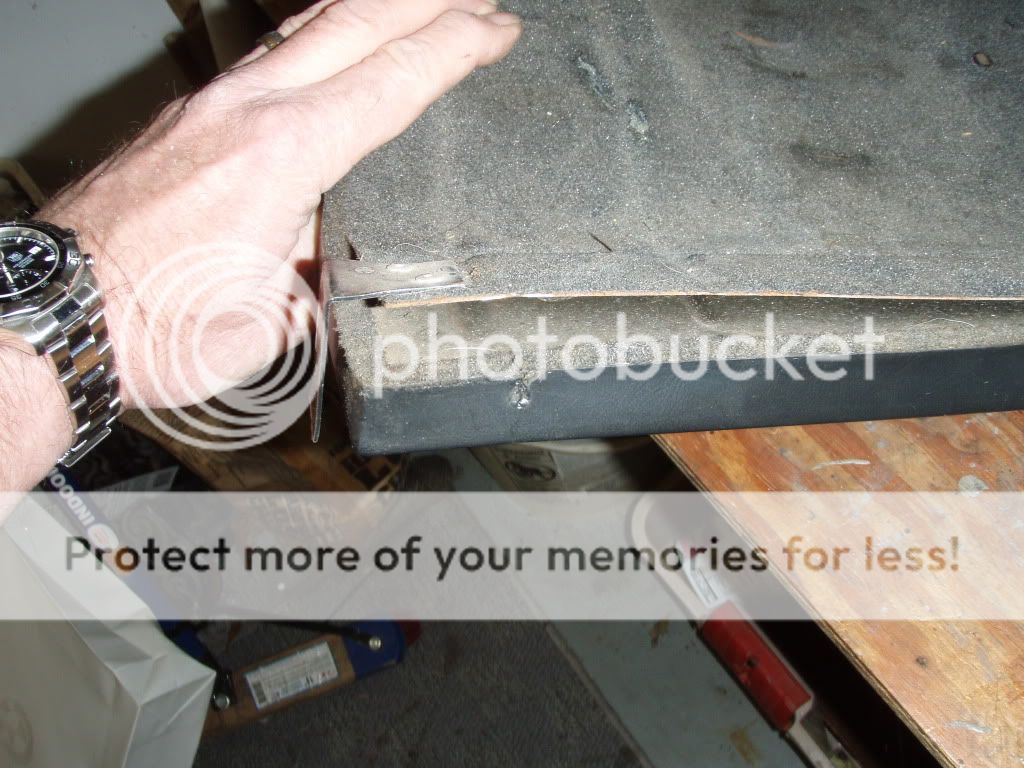

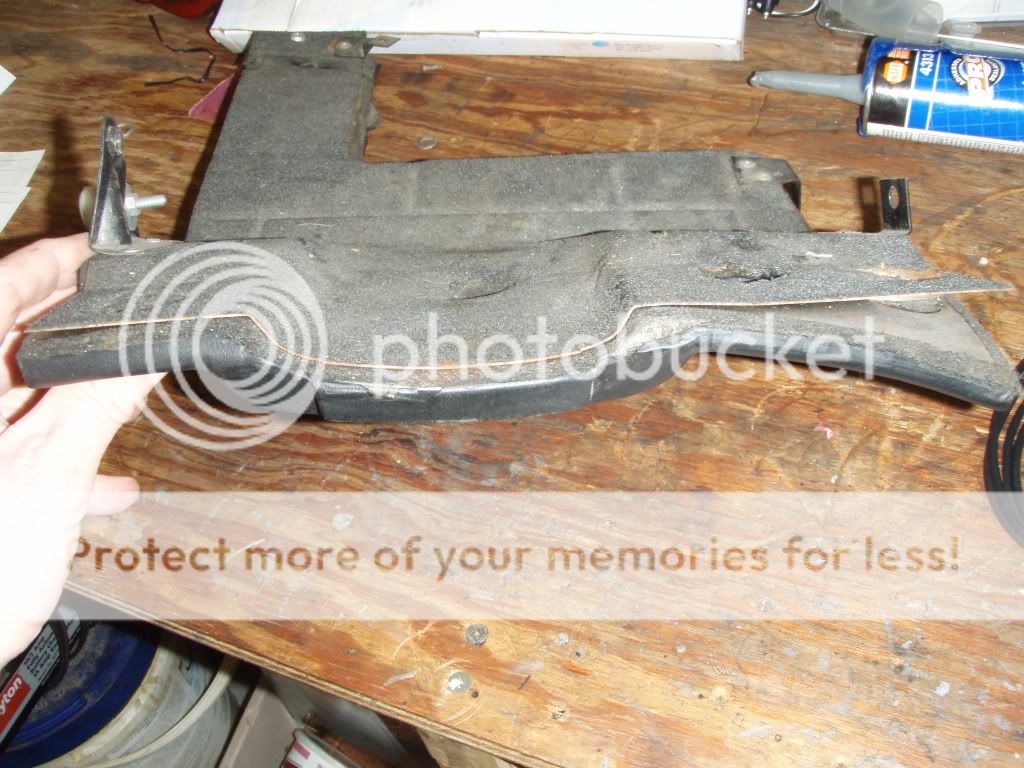

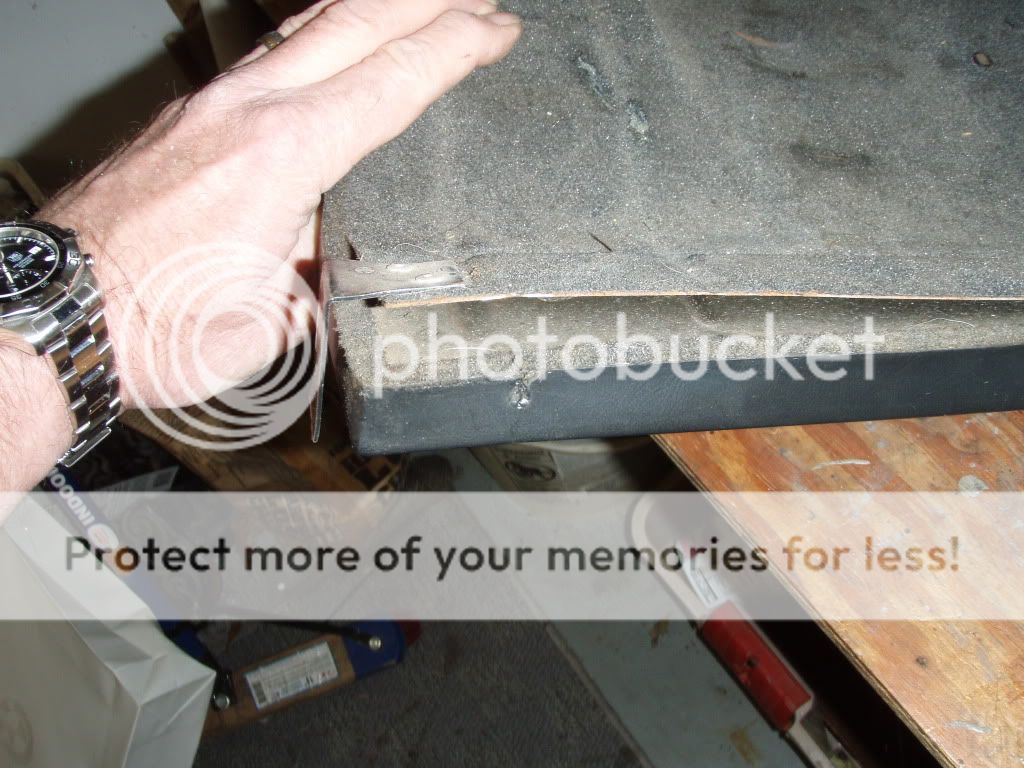

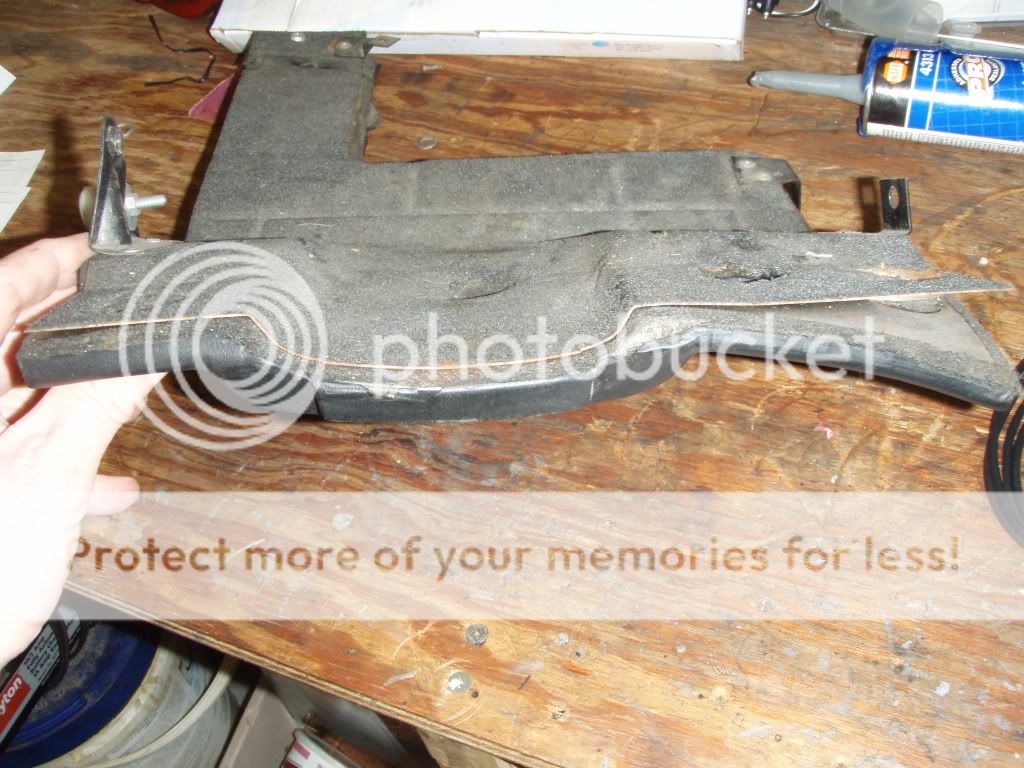

Any good way of glueing this back together? It's the panel under the instruments and steering column. I don't think just spraying in the upholstery contact glue will work as both sides are probably both dirty and rusty.

Remove the whole panel from the metal backing, clean, and then use what? Or do I have to make a whole new section of whatever this thing is made of?

Remove the whole panel from the metal backing, clean, and then use what? Or do I have to make a whole new section of whatever this thing is made of?