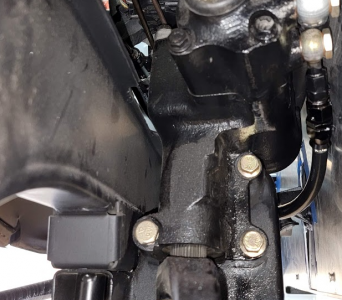

We are thankfully getting close to installing the engine/tranny assembly. We have a lift so the entire assembly came out from the bottom of course with the front suspension carrier.

When we removed it, all the accessories, ps pump, alternator, AC compressor, etc had already been removed, Plus both intake and exhaust manifolds were off. So other than the trick of uncoupling the steering from the box, it was fairly straight forward, albeit a little scary, well maybe more than a little scary when first lifting the car body.

However, going back in we would like to install as much "stuff" as possible before hand. Reasoning is with fresh paint, why risk any damage say installing the exhaust manifold, etc. lift over the fenders plus the ease of installing components on the floor.

So what experiences and gotchas have others had in doing so. We did watch Peter's video and it looked like he pretty much had everything already on, save the carbs.

jjs2800cs

When we removed it, all the accessories, ps pump, alternator, AC compressor, etc had already been removed, Plus both intake and exhaust manifolds were off. So other than the trick of uncoupling the steering from the box, it was fairly straight forward, albeit a little scary, well maybe more than a little scary when first lifting the car body.

However, going back in we would like to install as much "stuff" as possible before hand. Reasoning is with fresh paint, why risk any damage say installing the exhaust manifold, etc. lift over the fenders plus the ease of installing components on the floor.

So what experiences and gotchas have others had in doing so. We did watch Peter's video and it looked like he pretty much had everything already on, save the carbs.

jjs2800cs