Hi All - I had a gut-wrenching discovery last week as I reached a major milestone on my restoration, and could use some help understanding what could have gone wrong and what to do next. Long story short, my basically new, fully-built engine (by Korman) appears to have bent valves and contact dents on several of the pistons with correlated low compression, and I cannot understand why.

Here is the longer version: Back in 2020, Korman completed a complete top to bottom build replacing almost every part in the engine and fully building as new. Here are the relevant build details:

Once complete, the engine was shipped back, where it was (relatively) promptly set in the car with the peripherals and filled with oil, but ultimately not progressed much past that point for a few years

Flash forward to current time. I finally got in the electrical system, completed the fuel system, and finished off all the other bits around the engine. Before attempting to start, I changed and checked the oil, removing the valve cover to make sure there was oil across the entire head and chain tensioner. From there I followed Korman’s start procedures first rotating the engine manually, then cranking by starter with fuel and ignition deactivated till the oil was properly pressurized. After that, hooked everything back up, and it fired up pretty easily, but with a notable miss that did not improve after letting it run for a short period.

At this point, I did a compression test, noting four cylinders that are low (100-130), two are zero. To look into the issue, I bought a bore scope, which is where I discovered the obvious valve marks (pics below) - some worse than others, a couple with no mark that I can see. I can however only see one side of the piston, so not sure if the other valve hit on the other side of the piston

Even though I believe the engine should still be non-interference, my first thought was to check the cam timing. I checked the alignment of the cam gear and cam lobes on two rotations (pics below showing #1 lobes up and down at TDC), and from what I can tell, it looks dead on.

And so I am left with the question of what happened? The engine is basically new, always properly lubed (still has assembly lube on it), timing appears correct, carefully went through start procedures, and the damage is not consistent across all cylinders. The one theory I have is that the valve clearances may have been incorrectly set during the build, but would love some advice from others here that know more than I if this is the answer and where to go from here.

UPDATE (2025): After a long time of trying to figure this out with no answer, I simply called up Carl@Korman. After a short conversation, they let me know this was mostly likely an issue that took place during the build and quickly took the engine back and fixed at no cost! Kudos to Korman for standing behind their work and taking care of me despite the fact that it had been nearly four years already since I had the engine built before I got it in the car.

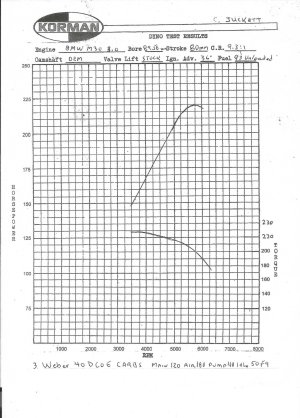

Here is the longer version: Back in 2020, Korman completed a complete top to bottom build replacing almost every part in the engine and fully building as new. Here are the relevant build details:

- Original ‘73 Block w/later ‘78 head (as recommended by Korman, my original had micro cracks)

- Nearly every part is new except the original stock crank, cam and a few other bits. All new valvetrain, pistons, rods, bearings, seals, etc

- Higher euro spec compression 9.5:1 forged pistons, slightly overbore

- Pics of build included

Once complete, the engine was shipped back, where it was (relatively) promptly set in the car with the peripherals and filled with oil, but ultimately not progressed much past that point for a few years

Flash forward to current time. I finally got in the electrical system, completed the fuel system, and finished off all the other bits around the engine. Before attempting to start, I changed and checked the oil, removing the valve cover to make sure there was oil across the entire head and chain tensioner. From there I followed Korman’s start procedures first rotating the engine manually, then cranking by starter with fuel and ignition deactivated till the oil was properly pressurized. After that, hooked everything back up, and it fired up pretty easily, but with a notable miss that did not improve after letting it run for a short period.

At this point, I did a compression test, noting four cylinders that are low (100-130), two are zero. To look into the issue, I bought a bore scope, which is where I discovered the obvious valve marks (pics below) - some worse than others, a couple with no mark that I can see. I can however only see one side of the piston, so not sure if the other valve hit on the other side of the piston

Even though I believe the engine should still be non-interference, my first thought was to check the cam timing. I checked the alignment of the cam gear and cam lobes on two rotations (pics below showing #1 lobes up and down at TDC), and from what I can tell, it looks dead on.

And so I am left with the question of what happened? The engine is basically new, always properly lubed (still has assembly lube on it), timing appears correct, carefully went through start procedures, and the damage is not consistent across all cylinders. The one theory I have is that the valve clearances may have been incorrectly set during the build, but would love some advice from others here that know more than I if this is the answer and where to go from here.

UPDATE (2025): After a long time of trying to figure this out with no answer, I simply called up Carl@Korman. After a short conversation, they let me know this was mostly likely an issue that took place during the build and quickly took the engine back and fixed at no cost! Kudos to Korman for standing behind their work and taking care of me despite the fact that it had been nearly four years already since I had the engine built before I got it in the car.

Last edited: