Paul Wegweiser

Well-Known Member

I've seen this mentioned, but no link or explanation for it anywhere, EVEN using the search function here.

Anyone care to elaborate on exactly what the "Jim Rowe Power Valve modification" IS????

I've finally hooked a wideband / AFR gauge into my 3.0 with 38/38 Webers and have decent fuel mixtures until going for 3/4 or greater throttle position....then things get WAY rich like I'm dumping raw fuel into the manifolds. Car runs reasonably well (even with those nasty rich mixtures), but I know I can get more top end if I can dial in the mixtures above 4000 rpm. My goal is 12.9 at WOT / high rpm.

I'm going to re-check float levels AGAIN... but curious about this modification - and if it has benefits for my situation.

Yes: Checked for fully opened choke plates - so all good there.

Currently going with this set-up (after hours upon hours of trial and error and endless test drives)

3.0 motor (stock)

135 mains

200 airs (was running 185s... before that, running 170s)

60 idles

Fuel mixtures expressed in AFR (93 Octane street fuel w some Ethanol):

idle 13.3-14.9 (I've found my 2002s and tiis like 12.9 exactly... no more... no less)

transition 11.8-13.0 (smooth, seamless...finally!)

cruise (interstate, light load, 70 mph) 13.0-15.8

3/4 or more throttle: 10.0 or less (!!!)

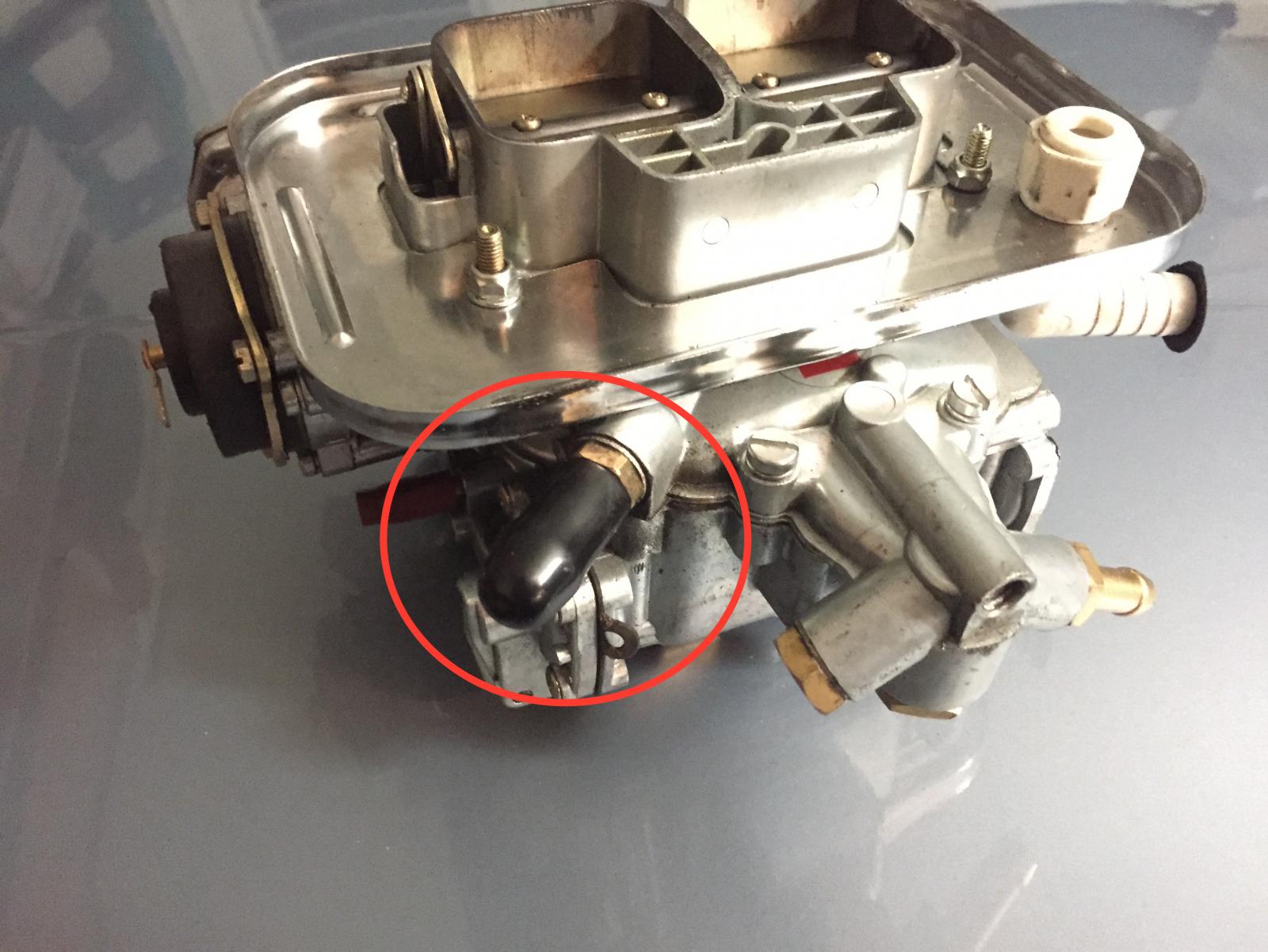

I'm thinking either unmetered fuel (power valve or float level) is dumping into the motor.

Carbs are brand new and genuine Weber... so I have little reason to suspect float or Power valve "malfunction"...though it's possible, of course.

I'm well versed in Weber things after 35+ years of tinkering.... but this one Mystifies me.

Thanks in advance!

Paul

Anyone care to elaborate on exactly what the "Jim Rowe Power Valve modification" IS????

I've finally hooked a wideband / AFR gauge into my 3.0 with 38/38 Webers and have decent fuel mixtures until going for 3/4 or greater throttle position....then things get WAY rich like I'm dumping raw fuel into the manifolds. Car runs reasonably well (even with those nasty rich mixtures), but I know I can get more top end if I can dial in the mixtures above 4000 rpm. My goal is 12.9 at WOT / high rpm.

I'm going to re-check float levels AGAIN... but curious about this modification - and if it has benefits for my situation.

Yes: Checked for fully opened choke plates - so all good there.

Currently going with this set-up (after hours upon hours of trial and error and endless test drives)

3.0 motor (stock)

135 mains

200 airs (was running 185s... before that, running 170s)

60 idles

Fuel mixtures expressed in AFR (93 Octane street fuel w some Ethanol):

idle 13.3-14.9 (I've found my 2002s and tiis like 12.9 exactly... no more... no less)

transition 11.8-13.0 (smooth, seamless...finally!)

cruise (interstate, light load, 70 mph) 13.0-15.8

3/4 or more throttle: 10.0 or less (!!!)

I'm thinking either unmetered fuel (power valve or float level) is dumping into the motor.

Carbs are brand new and genuine Weber... so I have little reason to suspect float or Power valve "malfunction"...though it's possible, of course.

I'm well versed in Weber things after 35+ years of tinkering.... but this one Mystifies me.

Thanks in advance!

Paul