Just removed flywheel as part of 5-speed conversion on 70 2800CS. Attached is photo of flywheel and it is worn. The friction wear surface is scarred. Estimate the wear from the bolt surface where pressure plate attaches is .030" to .040" down.

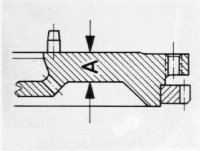

Can we have the wear surface smoothed by a shop as long as we do not go beyond the .532" distance shown from the factory manual diagram which is attached?

The question is the manual diagram actually shows the friction surface raised from the pressure plate bolting surface whereas mine is recessed the .030" plus..

Is mine worn that much or am I missing something here?

It appears that my distance "A" from the diagram will be just a few thousands less that the minuimum .532" specified after the friction surface is machined.

Also does the surface that the pressure plate bolts to also gets shaved along with the friction surface?

If mine is shot where can I get a good used one?

Thanks

jjs2800CS

Can we have the wear surface smoothed by a shop as long as we do not go beyond the .532" distance shown from the factory manual diagram which is attached?

The question is the manual diagram actually shows the friction surface raised from the pressure plate bolting surface whereas mine is recessed the .030" plus..

Is mine worn that much or am I missing something here?

It appears that my distance "A" from the diagram will be just a few thousands less that the minuimum .532" specified after the friction surface is machined.

Also does the surface that the pressure plate bolts to also gets shaved along with the friction surface?

If mine is shot where can I get a good used one?

Thanks

jjs2800CS