Moved this over from the E3 discussion hoping for more visibility:

Originally thought I had a problem with new fuel pump and regulator, however pressure is solid at 2.7 psi.

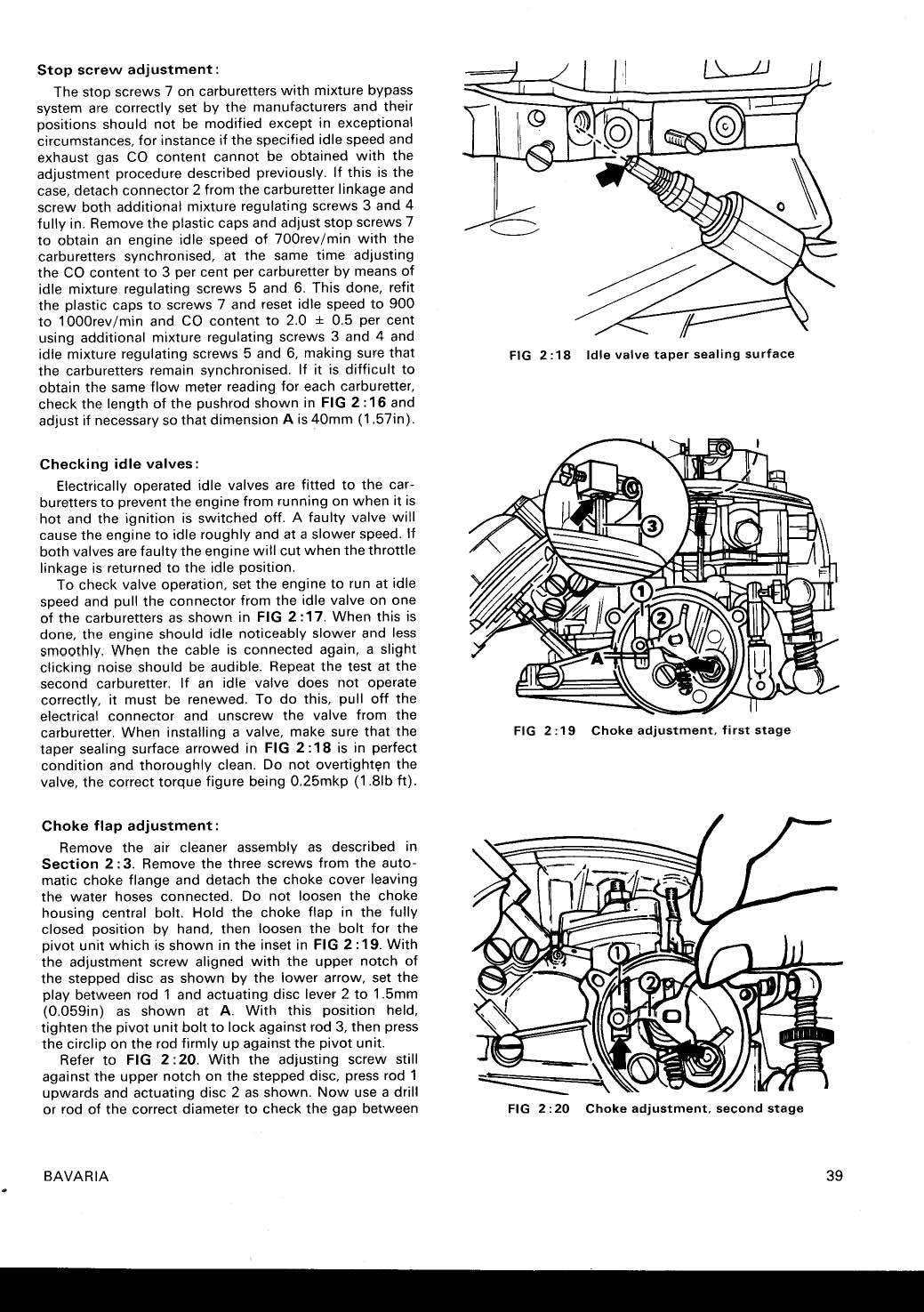

Installed Fuel Shut-off Solenoids in a pair of Weber 38's with electric choke. Car does not want to idle with them installed.

Solenoids appear to function properly (retract) when bench tested with 12 V.

On the car, having ZERO luck with both installed, tried to just tinker with one at a time. Now have the car properly tuned and idling just fine without the solenoids installed. Then I installed the front solenoid and restart the car. Idle is poor and low. Then hook up 12V directly from battery to solenoid and no change. Always blip the throttle inbetween to reset the idle but still no joy with the solenoid installed. Then swap the solenoid back out and restart and car runs fine.

On the bench, solenoids appear to function normally when power applied.

Does not make sense that they dont work when installed. Checked that carb provides a proper ground for solenoids as well. The solenoids are new units, I actually have 4 of them.

Am I supposed to change the size of the small brass jet-like object that fits in the end to accomodate the solenoid plunger?

Any thoughts or assistance appreciated.

Seems the problems in the original post were actually caused by the solenoids and not the fuel pump (forgot to mention that I had also made that change at the same time as the install). Should have stuck to the practice of not changing more than one part at a time.

__________________

Originally thought I had a problem with new fuel pump and regulator, however pressure is solid at 2.7 psi.

Installed Fuel Shut-off Solenoids in a pair of Weber 38's with electric choke. Car does not want to idle with them installed.

Solenoids appear to function properly (retract) when bench tested with 12 V.

On the car, having ZERO luck with both installed, tried to just tinker with one at a time. Now have the car properly tuned and idling just fine without the solenoids installed. Then I installed the front solenoid and restart the car. Idle is poor and low. Then hook up 12V directly from battery to solenoid and no change. Always blip the throttle inbetween to reset the idle but still no joy with the solenoid installed. Then swap the solenoid back out and restart and car runs fine.

On the bench, solenoids appear to function normally when power applied.

Does not make sense that they dont work when installed. Checked that carb provides a proper ground for solenoids as well. The solenoids are new units, I actually have 4 of them.

Am I supposed to change the size of the small brass jet-like object that fits in the end to accomodate the solenoid plunger?

Any thoughts or assistance appreciated.

Seems the problems in the original post were actually caused by the solenoids and not the fuel pump (forgot to mention that I had also made that change at the same time as the install). Should have stuck to the practice of not changing more than one part at a time.

__________________