MMercury

Well-Known Member

- Messages

- 481

- Reaction score

- 6

Nomenclature observations and a couple of related questions.

A recent question about the availability of a giubo with a seemingly experienced BMW parts man resulted in a frustrating exercise. In fact, despite using the language found in the shop manual, none of the people on the other side of the counter understood what I was describing until I said "black licorice-colored rubber doughnut."

FWIW, the shop manual agrees AND disagrees with TonyVelocewestS' take on the correct spelling of Giubo. The "3.75 amendment" uses the "GIUBO" spelling. The 3.75 amendment also describes the same part as "Giubo coupling/joint disc." However, the "1.76 amendment" lists Torque specifications for "GUIBO" coupling. Page 26-11/1 (10.73 Alteration") seems to describe the same part as a "rubber clutch."

For even more variety, the same manual refers to the reinforced driveshaft coupling - typically used with automatics - as a "Jurid joint." Should it matter (when ordering parts), the coupling has also been referred to as a "universal joint" and driveline "connector."

As I am currently concerned with a 1973 model, I will stick (probably to my detriment with parts personnel) with "giubo" and "Jurid joint." :wink:

___________________________

On a distantly related subject, using different nomenclature, E9'er-Steve asked about replacing the stock solid rubber giubo with a "thinner" Jurid joint. http://www.e9coupe.com/forum/showthread.php?t=1032 BMW P/N 26111107832 (giubo) versus BMW P/N 26111109603 (a.k.a. "Jurid joint").

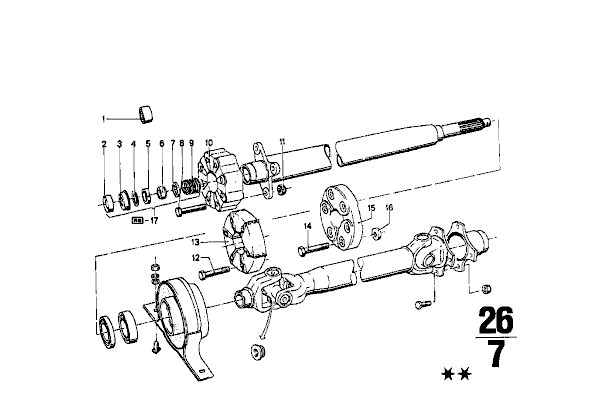

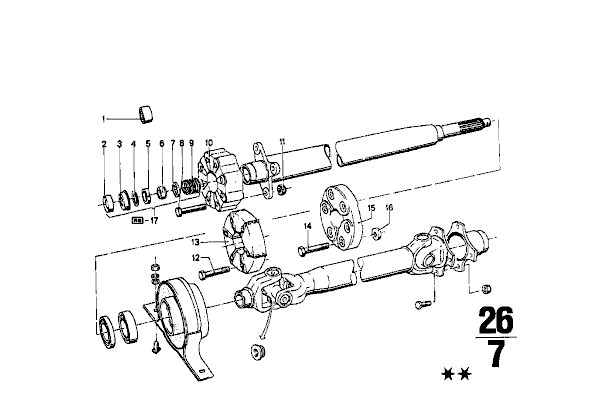

Short of sticking with the original part, as suggested by a Pacific-based E9'er, the Jurid joint can be used with individual 7.5mm (.295") shims or spacers - per the factory. BMW P/N 26111109626 and 26111109907. The former is described as a spacer "ring" while the latter is merely described as a spacer. I am unfamiliar with the difference. See No. 16 below:

Some have described this as a common upgrade. The stiffer, reinforced-Jurid joint may transmit more driveline vibration (although I have never noticed any). Anecdotally (since I have never measured the parts), it appears far more tolerant of rough treatment and long lived. The benefit of OEM giubo’s extra vibration absorption seems minor when used with the inherently smooth running inline M30. Contrariwise, a buzzy M10 might benefit from the solid rubber donut.

Two questions:

1. Has anyone found a readily available and less expensive substitute for these spacers? I had a box of surplus aircraft-grade spacers (0.295" long) that worked well, but managed to misplace them. (Grainger? Make my own?)

2. Jurid joints came in several sizes with bolt patterns identical to the OEM giubo. The outside diameters can differ by about 35mm. Apart from reduced clearance, additional weight/mass, and possibly extra stiffness for the larger diameter joint - both fit. Anyone using the larger joint, experience any issues suggesting the smaller joint is the preferred choice? (I have used the smaller OD joint, but happen to have a couple of larger diameter Joints collecting dust.)

Thanks

A recent question about the availability of a giubo with a seemingly experienced BMW parts man resulted in a frustrating exercise. In fact, despite using the language found in the shop manual, none of the people on the other side of the counter understood what I was describing until I said "black licorice-colored rubber doughnut."

FWIW, the shop manual agrees AND disagrees with TonyVelocewestS' take on the correct spelling of Giubo. The "3.75 amendment" uses the "GIUBO" spelling. The 3.75 amendment also describes the same part as "Giubo coupling/joint disc." However, the "1.76 amendment" lists Torque specifications for "GUIBO" coupling. Page 26-11/1 (10.73 Alteration") seems to describe the same part as a "rubber clutch."

For even more variety, the same manual refers to the reinforced driveshaft coupling - typically used with automatics - as a "Jurid joint." Should it matter (when ordering parts), the coupling has also been referred to as a "universal joint" and driveline "connector."

As I am currently concerned with a 1973 model, I will stick (probably to my detriment with parts personnel) with "giubo" and "Jurid joint." :wink:

___________________________

On a distantly related subject, using different nomenclature, E9'er-Steve asked about replacing the stock solid rubber giubo with a "thinner" Jurid joint. http://www.e9coupe.com/forum/showthread.php?t=1032 BMW P/N 26111107832 (giubo) versus BMW P/N 26111109603 (a.k.a. "Jurid joint").

Short of sticking with the original part, as suggested by a Pacific-based E9'er, the Jurid joint can be used with individual 7.5mm (.295") shims or spacers - per the factory. BMW P/N 26111109626 and 26111109907. The former is described as a spacer "ring" while the latter is merely described as a spacer. I am unfamiliar with the difference. See No. 16 below:

Some have described this as a common upgrade. The stiffer, reinforced-Jurid joint may transmit more driveline vibration (although I have never noticed any). Anecdotally (since I have never measured the parts), it appears far more tolerant of rough treatment and long lived. The benefit of OEM giubo’s extra vibration absorption seems minor when used with the inherently smooth running inline M30. Contrariwise, a buzzy M10 might benefit from the solid rubber donut.

Two questions:

1. Has anyone found a readily available and less expensive substitute for these spacers? I had a box of surplus aircraft-grade spacers (0.295" long) that worked well, but managed to misplace them. (Grainger? Make my own?)

2. Jurid joints came in several sizes with bolt patterns identical to the OEM giubo. The outside diameters can differ by about 35mm. Apart from reduced clearance, additional weight/mass, and possibly extra stiffness for the larger diameter joint - both fit. Anyone using the larger joint, experience any issues suggesting the smaller joint is the preferred choice? (I have used the smaller OD joint, but happen to have a couple of larger diameter Joints collecting dust.)

Thanks

Last edited: