Vintage56

Active Member

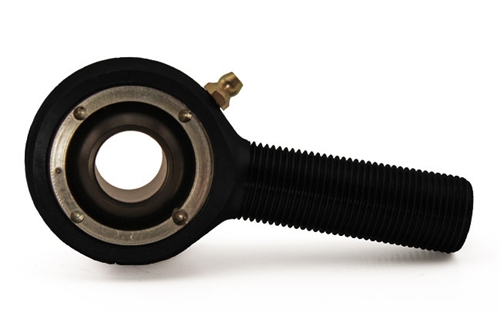

Hello Everyone. I had a simple question (but maybe there's no simple answer): since the E9's ball joints and tie rod ends do not have grease fittings, I am thinking about adding 6 of them to the front end components of my 1971 3.0cs. I wanted to ask if others have done this and if there are others who think that this is not a good step to take.

My thoughts are that the grease fittings, if there, would extend the life of the suspension components, as opposed to leaving them as they are knowing the grease will eventually harden and quicken their demise. I plan to drill small holes in the ball joints and tie rods and then cut some threads into the holes with correctly-sized taps.

I have seen others use needle extensions on the tips of their grease gun to pierce the boots and insert grease into the joint. But, using this method, I don't see how the grease would be put into the exact place where the joints meet. Plus the boot would be pierced exposing the joint to the elements/dirt/etc. I also thought of sealing the holes made with weatherstripping cement, but still don't see how the grease would get to the exact place where it should be and just fill up the boot.

Has anyone done the grease fitting modification I am suggesting and has it made any difference?

Thanks for the feedback.

My thoughts are that the grease fittings, if there, would extend the life of the suspension components, as opposed to leaving them as they are knowing the grease will eventually harden and quicken their demise. I plan to drill small holes in the ball joints and tie rods and then cut some threads into the holes with correctly-sized taps.

I have seen others use needle extensions on the tips of their grease gun to pierce the boots and insert grease into the joint. But, using this method, I don't see how the grease would be put into the exact place where the joints meet. Plus the boot would be pierced exposing the joint to the elements/dirt/etc. I also thought of sealing the holes made with weatherstripping cement, but still don't see how the grease would get to the exact place where it should be and just fill up the boot.

Has anyone done the grease fitting modification I am suggesting and has it made any difference?

Thanks for the feedback.