Rear lifting points; how too part 2

To 61 Porsche, Peter and others; thanks for your tips.

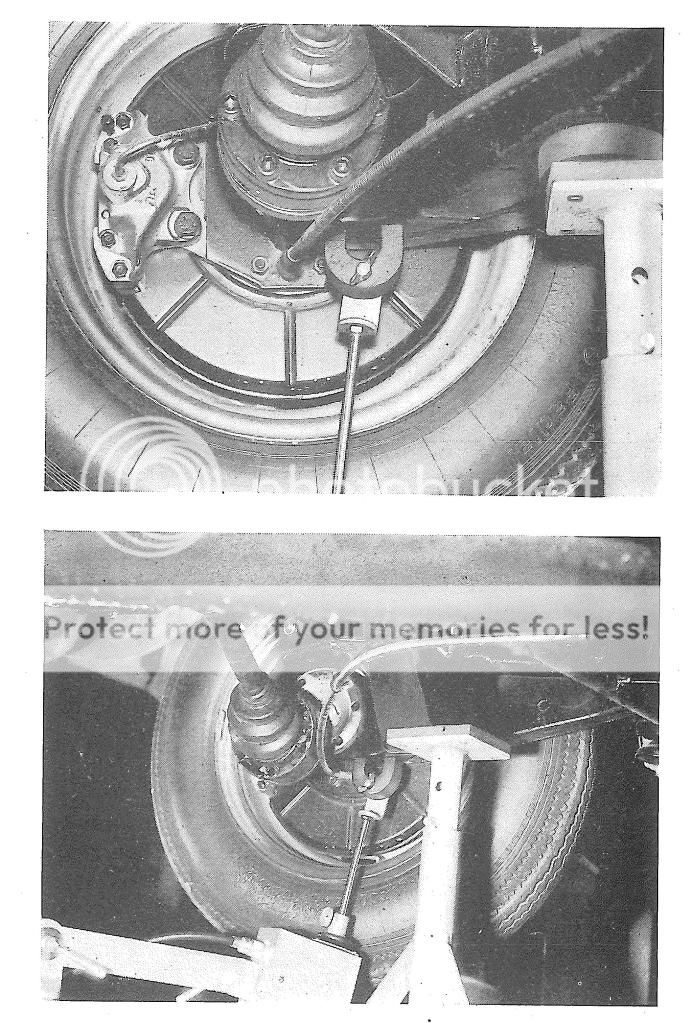

Here some pics of the lifting i'm conducting with your advise (rear right wheel pictured), and a shot of the underside (looking up) at the rear subframe mounting points where the floor under the rear seat is disappearing as we speak.

The lifting device keeps the car nicely horizontal, so no body torque. Thanks Porsche 61; I did not think about the negative effect of body twist during welding, but luckily my 4-point lifting device keeps it straight; the doors open although a bigger pull is needed.

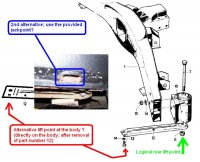

As you can see, i have been challenged by the advise of 61Porsche. I could not fit a hardwood block to stradle the inside and outside rocker, as the inside rocker at the rear goes straight up, having no edge to rest on.

So having no better idea :-?, i shaped a wood block to fill the jacking point, and lifted it up from there. It's been up now for a few days, and it's still holding up.

Why should we preferably not use the provided jacking points? Are these designed too weak, or are they prone to rust through and then become too weak? My rockers appear to be solid, the car was ovehauled some 10 years ago, and has been driven without the add-on sills since.

Porsche 61, 2 questions;

- you mention the "body repair section". What document is that / where to find it? I have the feeling that your comment is like a rainbow...at the end is a pot with...instructions! Always helpfull for a novice as me.

- you mention to reinforce the area under the rear seats. I indeed have removed all from the rear of the car, so it's accessible. What type(s) of reinforcement do you mean? I assume for lateral stifness, but how should i execute that?

Hoping to have him/her back on the road for the spring. I'm finding some other rust spots, i assume typical:

- in the trunk on the flange where the fueltank rests on (a may 1973 car)

- in the corners where the wheelhouse meets the bootfloor and the rearquarter skin; there seems to be a OEM puch through type hole there..Why for godsake? This is probably the reason why my luggage compartment was full of muddy water; spray from the rear wheel. This won't be easy to fix i think, as it's a joint of 3 panels. i suppose i have to cut open the wheelhouse from the side of the wheel to get good access.

- between the rear window and the bootlid is 2 cm of body visible, there are some small holes, about 3 mm diameter. Strange, because the metal around it is solid, and the holes are straight through. It almost seems they are drilled.

- I am also planning to reroute the water drain from the c-pillar badge and have it exit somewhere in the trunk

i'll probaby be posting some pics and questions as i progress, to get some feedback on how things should be done.

Regards,

Erik, The Netherlands.