(I think I'll build a DIY from it in due time, but I first want to check some things + I still need one thing solved - see questions to the group below

‐--------

My car came to me with 4 different keys. Which worked for me; my car was a real drivers car. But I always wanted to have less hassle, so I actually rekeyed my driver's doorlock to the (original) ignition and glovebox.

Each lock has a code on it. On the door locks they are stamped onto the little actuator. (See pic)

Lock basics:

The locks have 2 rows of 3 pins each. The pins come in 3 different lengths:

4.95 mm, 5.45 mm and 5.98 mm.

(Sorry about the mm's).

Each pin has a corresponding cup; a short pin is matched to a long cup. Thus the cups also come in 3 different lengths: 3.09 mm 2.58 mm and 2.11 mm.

So, the 4.95 pin is matched to the 3.09 cup.

(The measurements of the pins and cups could well be just steps of 0.5 mm eg pins are nominal 5.0 mm 5.5mm and 6.0 mm. Perhaps my pins have worn?)

The pin and cup are pressed into the key with small springs.

A row of 3 holes is beneath each silver pressed plate.

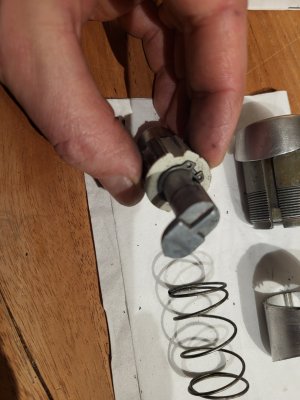

Below a pic of the individual parts.

If you want to re key (rekey?) a lock, it means you have to start by prying off the stainless steel plate with a tiny screwdriver. In a clean and tidy place, where you can easily find the small parts on the floor. Because they will want to jump out. If you keep some pressure on the plate, you can let it pop up a few mm's and release the spring pressure.

The pins have a sharp point that fit into the dimples of the key. The other end of the pin is smooth, and should lie flat with the barrel outer surface. In that way, the pins rotate, while the cups with springs remain in their slot when the lock (the inner barrel) is rotated.

Once you have all the pins, cups, and springs out, you need to figure out what code you need, and then count if you have enough pins and cups of the correct lengths.

The assembly: start with one side.

Insert the 3 pins their respective cups, 3 springs, and place the lid. Bend back whatever is left of the small metal tabs that are left to keep the plate down.

Repeat on the other side.

All locks use the same principle.

to you all:

Question 1: My DIY attempt, about 7 years ago, worked nicely for 4 years. Now, somewhere during the past, one of the stainless steel plates fell off, spilling springs, cups and pins inside the door. So my attempt to lock the stainless plate back by bending the minute edges flat wasn't 100% OK.

- what do other people (keys4classics?) use to reseal these stainless plates? Glue? Metal circular clamp (but must be very thin, as the M24 nut needs to slide over it)?

Question 2: i think i read on the forum somewhere this: who can confirm:

- valet key has 7 dimples, normal keys have 6 dimples. The valet key open all, but not trunk nor glovebox.

Seems counterintuitive to me, as I'd expect the valet key to have one less dimple, thus not activating (opening) pin#7 of the glovebox.

‐--------

My car came to me with 4 different keys. Which worked for me; my car was a real drivers car. But I always wanted to have less hassle, so I actually rekeyed my driver's doorlock to the (original) ignition and glovebox.

Each lock has a code on it. On the door locks they are stamped onto the little actuator. (See pic)

Lock basics:

The locks have 2 rows of 3 pins each. The pins come in 3 different lengths:

4.95 mm, 5.45 mm and 5.98 mm.

(Sorry about the mm's).

Each pin has a corresponding cup; a short pin is matched to a long cup. Thus the cups also come in 3 different lengths: 3.09 mm 2.58 mm and 2.11 mm.

So, the 4.95 pin is matched to the 3.09 cup.

(The measurements of the pins and cups could well be just steps of 0.5 mm eg pins are nominal 5.0 mm 5.5mm and 6.0 mm. Perhaps my pins have worn?)

The pin and cup are pressed into the key with small springs.

A row of 3 holes is beneath each silver pressed plate.

Below a pic of the individual parts.

If you want to re key (rekey?) a lock, it means you have to start by prying off the stainless steel plate with a tiny screwdriver. In a clean and tidy place, where you can easily find the small parts on the floor. Because they will want to jump out. If you keep some pressure on the plate, you can let it pop up a few mm's and release the spring pressure.

The pins have a sharp point that fit into the dimples of the key. The other end of the pin is smooth, and should lie flat with the barrel outer surface. In that way, the pins rotate, while the cups with springs remain in their slot when the lock (the inner barrel) is rotated.

Once you have all the pins, cups, and springs out, you need to figure out what code you need, and then count if you have enough pins and cups of the correct lengths.

The assembly: start with one side.

Insert the 3 pins their respective cups, 3 springs, and place the lid. Bend back whatever is left of the small metal tabs that are left to keep the plate down.

Repeat on the other side.

All locks use the same principle.

to you all:

Question 1: My DIY attempt, about 7 years ago, worked nicely for 4 years. Now, somewhere during the past, one of the stainless steel plates fell off, spilling springs, cups and pins inside the door. So my attempt to lock the stainless plate back by bending the minute edges flat wasn't 100% OK.

- what do other people (keys4classics?) use to reseal these stainless plates? Glue? Metal circular clamp (but must be very thin, as the M24 nut needs to slide over it)?

Question 2: i think i read on the forum somewhere this: who can confirm:

- valet key has 7 dimples, normal keys have 6 dimples. The valet key open all, but not trunk nor glovebox.

Seems counterintuitive to me, as I'd expect the valet key to have one less dimple, thus not activating (opening) pin#7 of the glovebox.

Attachments

Last edited: