Basic maintenance time. Front discs!

(Writing this down bc it had been a long time since I had done it and I had forgotten several steps)

Items needed:

- New discs BMW # 34 11 1 108 131

- New pads ATE # 609030

- Brake cleaning fluid

- Wheel bearing grease

- Blue Loctite

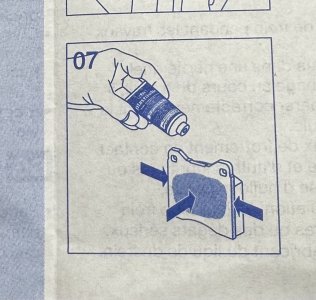

- Copper grease or equivalent brake pad lubrication

- Possibly new brake fluid if you do a top up or bleed

Tools needed:

- Sturdy jackstands

- Breaker bar with short 19 mm socket for caliper bolts

- Ratchet and deep 13 mm socket for the break line bracket

- 24 mm socket for the castellated nut

- 8 mm hex key to attach the disc onto the hub

- Needle nose pliers for the cotter pin

- A brake pad spreader will make inserting the new pads much easier. ($40 on Amazon) If not you can use a C clamp but it is pretty hard because you have to hold that caliper in one hand while trying to tighten that dangling C clamp with another

- Torque wrench

- Chisel and mallet for prying the wheel bearing dust cup out

- Disposable gloves

- Coat hanger or similar to hold the caliper while it is out

- Lights. I use 2 kinds: One magnet I can stick inside the wheel well pointed at the work. And one flexible headband type that lights where I am looking

- Nylon bristle brush to clean up the parts

- Brass bristle "pipe cleaner" type of tool to clean bolt holes

- A couple of different small containers to hold the parts that are being taken out gloves because things are going to get dirty

- Lots of shop towels

(Writing this down bc it had been a long time since I had done it and I had forgotten several steps)

Items needed:

- New discs BMW # 34 11 1 108 131

- New pads ATE # 609030

- Brake cleaning fluid

- Wheel bearing grease

- Blue Loctite

- Copper grease or equivalent brake pad lubrication

- Possibly new brake fluid if you do a top up or bleed

Tools needed:

- Sturdy jackstands

- Breaker bar with short 19 mm socket for caliper bolts

- Ratchet and deep 13 mm socket for the break line bracket

- 24 mm socket for the castellated nut

- 8 mm hex key to attach the disc onto the hub

- Needle nose pliers for the cotter pin

- A brake pad spreader will make inserting the new pads much easier. ($40 on Amazon) If not you can use a C clamp but it is pretty hard because you have to hold that caliper in one hand while trying to tighten that dangling C clamp with another

- Torque wrench

- Chisel and mallet for prying the wheel bearing dust cup out

- Disposable gloves

- Coat hanger or similar to hold the caliper while it is out

- Lights. I use 2 kinds: One magnet I can stick inside the wheel well pointed at the work. And one flexible headband type that lights where I am looking

- Nylon bristle brush to clean up the parts

- Brass bristle "pipe cleaner" type of tool to clean bolt holes

- A couple of different small containers to hold the parts that are being taken out gloves because things are going to get dirty

- Lots of shop towels

Last edited: