You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

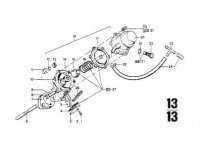

Mechanical fuel pump compatibility

- Thread starter Stevehose

- Start date

Mechanical Fuel Pumps

Same pump. First design, if with screen. Second, no provision for screen, and yours is the last- can't be rebuilt. (Pressed Cap)

There was one on ebay recently - might still be there. If I recall about $50 there. Bought one a while back- paid about $100. Autohauz when BMW wanted $200, I guess because Pierburg's stock was low at the time.

Buy the gasket and the bushes for the bolts.:-D

Same pump. First design, if with screen. Second, no provision for screen, and yours is the last- can't be rebuilt. (Pressed Cap)

There was one on ebay recently - might still be there. If I recall about $50 there. Bought one a while back- paid about $100. Autohauz when BMW wanted $200, I guess because Pierburg's stock was low at the time.

Buy the gasket and the bushes for the bolts.:-D

Guys,

You helped me with a 74 3.0 I was getting running for a friend last week. Running but still needs some tweaking. Thanks

My new purchase 5/10/12 72 3.0 CS had a new mech pump from autohausaz. purchased 6/15/11. It has failed?

Previous owner would have to send back.

I've tried everything to test it and it just doesn't pump. Even replaced the fuel line from the hard line pipe at the firewall to the filter (which I checked) as per a post on here about the lines sucking air.

Would you replace mech pump or just switch to low pressure electric?

Thanks,

Gary

You helped me with a 74 3.0 I was getting running for a friend last week. Running but still needs some tweaking. Thanks

My new purchase 5/10/12 72 3.0 CS had a new mech pump from autohausaz. purchased 6/15/11. It has failed?

Previous owner would have to send back.

I've tried everything to test it and it just doesn't pump. Even replaced the fuel line from the hard line pipe at the firewall to the filter (which I checked) as per a post on here about the lines sucking air.

Would you replace mech pump or just switch to low pressure electric?

Thanks,

Gary

jmackro

Well-Known Member

My new purchase 5/10/12 72 3.0 CS had a new mech pump from autohausaz. purchased 6/15/11. It has failed?

Previous owner would have to send back. I've tried everything to test it and it just doesn't pump. Even replaced the fuel line from the hard line pipe at the firewall to the filter (which I checked) as per a post on here about the lines sucking air.

Kind of surprising that a pump < 1 year old would fail. Are you sure it was installed properly? Did it ever work? Have you tried testing it off the car, with the inlet hose stuck in a gas can, and working the plunger by hand?

Would you replace mech pump or just switch to low pressure electric?

Lots has been written here on the e9 Forum about the pros & cons of converting to electric. If your coupe will be driven only occasionally, it is nice to have an elec. pump as you can prime the carbs without cranking the engine excessively.

Before

you junk it, back flush it with some solvent. Maybe WD40 but it's got to be the Chip Foose commemorative can.:roll:

There's a chance...... that debris has gotten under the check valve which must work in order to pump. Do not use air. The operating pressure of the pump is 2,1/2 lbs.

I would replace the pump. New ones can be had for less than $50 bucks with some shopping around. You can pay over $200 if you don't.

If you have the type that has a screwed flange rather than pressed- kits are available. Further, you can get to the check valves as described in the repair manual. Don't throw that type away.

you junk it, back flush it with some solvent. Maybe WD40 but it's got to be the Chip Foose commemorative can.:roll:

There's a chance...... that debris has gotten under the check valve which must work in order to pump. Do not use air. The operating pressure of the pump is 2,1/2 lbs.

I would replace the pump. New ones can be had for less than $50 bucks with some shopping around. You can pay over $200 if you don't.

If you have the type that has a screwed flange rather than pressed- kits are available. Further, you can get to the check valves as described in the repair manual. Don't throw that type away.

Tony_V

Active Member

Check the length of insulating flange and pushrod.Guys,

You helped me with a 74 3.0 I was getting running for a friend last week. Running but still needs some tweaking. Thanks

My new purchase 5/10/12 72 3.0 CS had a new mech pump from autohausaz. purchased 6/15/11. It has failed?

Previous owner would have to send back.

I've tried everything to test it and it just doesn't pump. Even replaced the fuel line from the hard line pipe at the firewall to the filter (which I checked) as per a post on here about the lines sucking air.

Would you replace mech pump or just switch to low pressure electric?

Thanks,

Gary

http://www.e9coupe.com/tech/autobooks/chapter2/autobooks_manual_035.htm

The pushrods and insulating block is only an issue with 2002s I believe. As this one worked for a year it should be fine. If the new pump is different, e.g. has a round spring instead of a finger to actuate, then rod must be changed.

The latest..........

I checked with a friend today and decided to pull the valve cover and check the eccentric lobe.

Everything seems normal there. Lobe is not worn abnormally and shaft seems to be in the proper place.

In messing with the pump the other day I found that I could take a screwdriver or my finger and with the fuel line hooked up I could press down farther on the rocker shaft in the pump and get volumes of gas.

Install on car and get little or nothing. There is some play where the pump arm moves and nothing happens.

I don't understand why but it seems that the shaft is too short to operate the pump where the actual travel starts? I think the shafts are all the same length???

Anyway decided since the spacers are cheap and easy to get I would put one on the belt sander and make it thinner therefor lengthening the shaft to exert more movement on the pump taking up the slack in the pump arm.

Sure doesn't explain the why but may work.

I'll let you know.

Thanks,

Gary

I checked with a friend today and decided to pull the valve cover and check the eccentric lobe.

Everything seems normal there. Lobe is not worn abnormally and shaft seems to be in the proper place.

In messing with the pump the other day I found that I could take a screwdriver or my finger and with the fuel line hooked up I could press down farther on the rocker shaft in the pump and get volumes of gas.

Install on car and get little or nothing. There is some play where the pump arm moves and nothing happens.

I don't understand why but it seems that the shaft is too short to operate the pump where the actual travel starts? I think the shafts are all the same length???

Anyway decided since the spacers are cheap and easy to get I would put one on the belt sander and make it thinner therefor lengthening the shaft to exert more movement on the pump taking up the slack in the pump arm.

Sure doesn't explain the why but may work.

I'll let you know.

Thanks,

Gary

How long is your pushrod? I have a spare with my emergency pump I can measure for comparison if you'd like.

Here is some info on rod lengths for the 2002 in case lengths are same for e9:

http://www.bmw2002faq.com/component...hlight,/sid,a150b8aeae2c5cae7a18649a53450d18/

http://www.bmw2002faq.com/component/option,com_forum/Itemid,57/page,viewtopic/t,294242

I had this issue on my 2002, the insulator and rod didn't work with newer pump, it was too short. I could get plenty of fuel by moving by hand. But if your pump was working and now it isn't I don't see how this could be the cause.

Chris

http://www.bmw2002faq.com/component...hlight,/sid,a150b8aeae2c5cae7a18649a53450d18/

http://www.bmw2002faq.com/component/option,com_forum/Itemid,57/page,viewtopic/t,294242

I had this issue on my 2002, the insulator and rod didn't work with newer pump, it was too short. I could get plenty of fuel by moving by hand. But if your pump was working and now it isn't I don't see how this could be the cause.

Chris

Warning! Will Robinson

The pump is capable of more pressure than your carbs can handle when the spacer is altered.

I once had the opposite problem where a PO altered the spacer thickness and a new replacement pump was putting out 10 psi. (Porsche)

It's more likely the "arms" ( actually a plate of sorts), are/ is bent or bowed or somehow not sitting right in place. That would explain the short stroke.

You can access those parts through the rectangular plate.

Better to only alter the plate only enough to get the required psi. Slowly.

Stock rod length- 107.2 mm +- 1mm

Stock spacer-20mm.

The pump is capable of more pressure than your carbs can handle when the spacer is altered.

I once had the opposite problem where a PO altered the spacer thickness and a new replacement pump was putting out 10 psi. (Porsche)

It's more likely the "arms" ( actually a plate of sorts), are/ is bent or bowed or somehow not sitting right in place. That would explain the short stroke.

You can access those parts through the rectangular plate.

Better to only alter the plate only enough to get the required psi. Slowly.

Stock rod length- 107.2 mm +- 1mm

Stock spacer-20mm.

How long is your pushrod? I have a spare with my emergency pump I can measure for comparison if you'd like.

Careful what you ask for?

It's 106mm's.

The pump is capable of more pressure than your carbs can handle when the spacer is altered.

I once had the opposite problem where a PO altered the spacer thickness and a new replacement pump was putting out 10 psi. (Porsche)

It's more likely the "arms" ( actually a plate of sorts), are/ is bent or bowed or somehow not sitting right in place. That would explain the short stroke.

You can access those parts through the rectangular plate.

Better to only alter the plate only enough to get the required psi. Slowly.

Stock rod length- 107.2 mm +- 1mm

Stock spacer-20mm.

This pump is less than a year old. A Pierburg.

I have had it apart a couple times trying to understand how and why it is not working. I even drove the pin out that the arm pivots on.

It is a pump that has screws around the flange and I would assume it could be rebuilt?

BTW this engine has downdraft Webers.

Yes,

screws around the daiphram cover indicates a rebuildable type. BMW sells the kits.

Take the pin back out and see if the arm ( a little bent plate) is in correctly, bent, or worn abnormally. The plate should have a split on the end with two tangs. Those are arms and should be parallel or even.

If you can measure the stroke, the rule of thumb is 42-36 mm.

I wouldn't shave more than 4 mm.

Downdraft webers or Zeniths; it doesn't matter until triple side drafts or racing when volume becomes an issue over psi.

screws around the daiphram cover indicates a rebuildable type. BMW sells the kits.

Take the pin back out and see if the arm ( a little bent plate) is in correctly, bent, or worn abnormally. The plate should have a split on the end with two tangs. Those are arms and should be parallel or even.

If you can measure the stroke, the rule of thumb is 42-36 mm.

I wouldn't shave more than 4 mm.

Downdraft webers or Zeniths; it doesn't matter until triple side drafts or racing when volume becomes an issue over psi.

I'll measure the rod. If you have opened the pump and removed the diaphragm, when you tighten the screws during reassembly you have to press the pivot arm down about halfway so that the membrane is in the middle of it's "stretch," then close it up. Otherwise it will be flat on one part of the pump cycle and overstretched on the other. I get all the screws almost tight then press it onto a piece of wood to actuate the lever while simultaneously tightening the screws the last bit.

This pump is less than a year old. A Pierburg.

I have had it apart a couple times trying to understand how and why it is not working. I even drove the pin out that the arm pivots on.

It is a pump that has screws around the flange and I would assume it could be rebuilt?

BTW this engine has downdraft Webers.

I'll measure the rod. If you have opened the pump and removed the diaphragm, when you tighten the screws during reassembly you have to press the pivot arm down about halfway so that the membrane is in the middle of it's "stretch," then close it up. Otherwise it will be flat on one part of the pump cycle and overstretched on the other. I get all the screws almost tight then press it onto a piece of wood to actuate the lever while simultaneously tightening the screws the last bit.

Great tip Steve. I will do that. Going to try again later this afternoon.

Yea, it's running!

This is a result of reducing the thickness of the spacer by 4-5 mm.

I drove around the block and it ran fine.

A little jerky but that may be me getting used to a different clutch.

I put new points,rotor and cap on as well.

Idle is too high so probably need to sync adjust the carbs.

I own a carb tune gauge for my M5 so should be easy to even carbs out. Also want to check timing? Got to read up on that. First time I have run a timing light in 10+ years.

Definitely a weird one. Something about the pump is not right?

Thanks for the help everyone.

Sure there will be something else.

Gary

This is a result of reducing the thickness of the spacer by 4-5 mm.

I drove around the block and it ran fine.

A little jerky but that may be me getting used to a different clutch.

I put new points,rotor and cap on as well.

Idle is too high so probably need to sync adjust the carbs.

I own a carb tune gauge for my M5 so should be easy to even carbs out. Also want to check timing? Got to read up on that. First time I have run a timing light in 10+ years.

Definitely a weird one. Something about the pump is not right?

Thanks for the help everyone.

Sure there will be something else.

Gary

Probably worth 60 bux or so to get a new pump and keep that one in the spare wheel well as a backup.