gazzol

Well-Known Member

Hi guys, don't post as often as I should however I thought I'd update you on my coupe.

About 10 years ago (yes really) I bought another engine for my coupe, the idea was that I would do a full overhaul with a few mods whilst keeping the car driveable. Sadly a few years ago a hard drive failure meant that most of the photos of the work I did on the engine were lost so a mostly written account will have to suffice.

Internally the motor has had the crank journals polished, new big end and main bearings, new oil pump ordered from BMW (couldn't sit down for a week) longer H beam rods, shorter forged pistons, stronger but still cast alloy cam followers, stronger valve springs, 290 degree cam and home made rocker locks instead of the springs and washers normally used to locate the cam followers. The whole rotating mass was sent to be balanced.

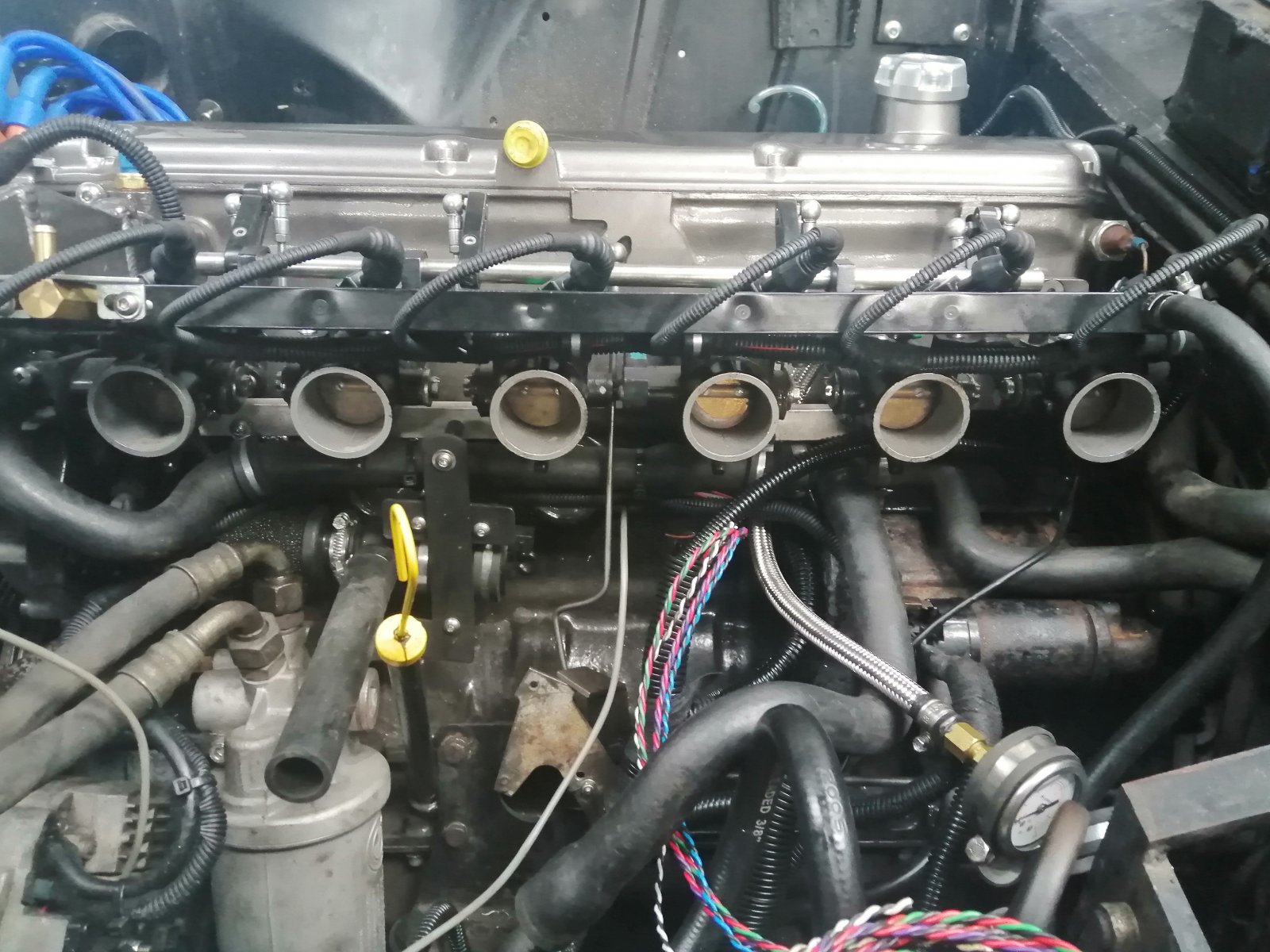

The cylinder head was ported by yours truly with new guides fitted and seats recut. Induction is via Triumph 959 individual throttle bodies mounted to an adapter plate which bolts directly to the cylinder head. There are home made ram pipes and an ITG air filter. Finally an Emerald K6 ecu controls the fuelling and ignition.

The old engine coming out

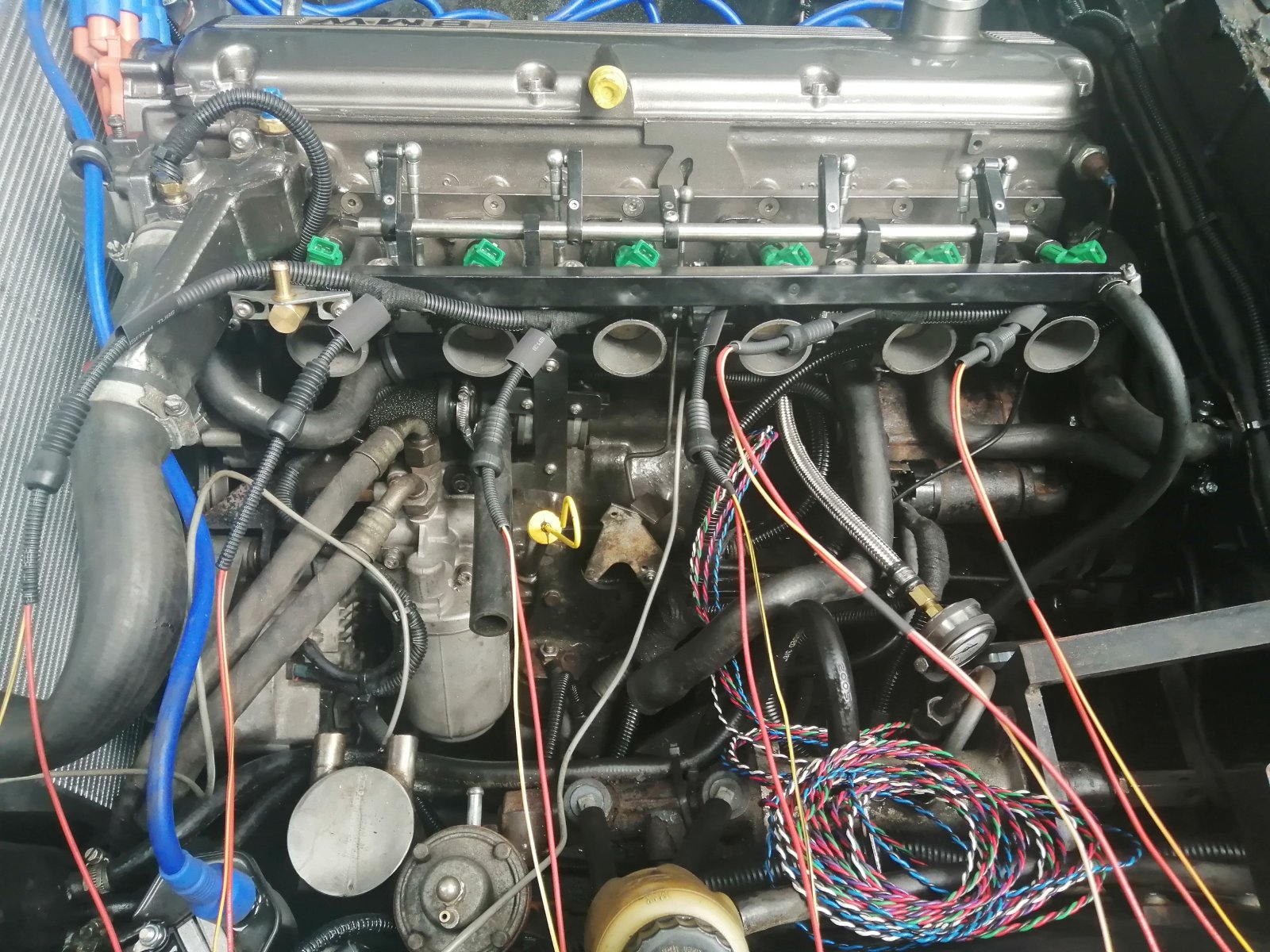

New engine in, work on the management harness begins.

Hmmm, I could be here a while.

Amongst many other adhock and unforseen modifications I had to move the coolant header tank which meant I had to order some longer hose to connect the tank to the cooling system which delayed progress by a week due to Easter and corona. On running the engine it was really rough and spitting back, it transpired that it was only running on the back 3 cylinders, lots of investigation later it was found that the injectors on cylinder 1 & 2 were stuck and started working after they'd been given a tap with the edge of a spanner but injector 3 still refused to play ball (or at least I thought) manually feeding the injector with 12V on the bench showed it to be working this was confirmed by blowing through it. Be careful if you try this ad they aren't designed to be run at 100% duty cycle without fuel flowing through them to cool them. Further investigation showed that injector 3 has no 12V feed which means I've made a mistake in the harness.

A job for tomorrow!

About 10 years ago (yes really) I bought another engine for my coupe, the idea was that I would do a full overhaul with a few mods whilst keeping the car driveable. Sadly a few years ago a hard drive failure meant that most of the photos of the work I did on the engine were lost so a mostly written account will have to suffice.

Internally the motor has had the crank journals polished, new big end and main bearings, new oil pump ordered from BMW (couldn't sit down for a week) longer H beam rods, shorter forged pistons, stronger but still cast alloy cam followers, stronger valve springs, 290 degree cam and home made rocker locks instead of the springs and washers normally used to locate the cam followers. The whole rotating mass was sent to be balanced.

The cylinder head was ported by yours truly with new guides fitted and seats recut. Induction is via Triumph 959 individual throttle bodies mounted to an adapter plate which bolts directly to the cylinder head. There are home made ram pipes and an ITG air filter. Finally an Emerald K6 ecu controls the fuelling and ignition.

The old engine coming out

New engine in, work on the management harness begins.

Hmmm, I could be here a while.

Amongst many other adhock and unforseen modifications I had to move the coolant header tank which meant I had to order some longer hose to connect the tank to the cooling system which delayed progress by a week due to Easter and corona. On running the engine it was really rough and spitting back, it transpired that it was only running on the back 3 cylinders, lots of investigation later it was found that the injectors on cylinder 1 & 2 were stuck and started working after they'd been given a tap with the edge of a spanner but injector 3 still refused to play ball (or at least I thought) manually feeding the injector with 12V on the bench showed it to be working this was confirmed by blowing through it. Be careful if you try this ad they aren't designed to be run at 100% duty cycle without fuel flowing through them to cool them. Further investigation showed that injector 3 has no 12V feed which means I've made a mistake in the harness.

A job for tomorrow!