You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Oooohhhh, too far gone maybe?

- Thread starter mr bump

- Start date

This will be interesting.

I'd say the chassis is rotten to the core. Suspect front screen been out a while so lots of rain ingress into the cabin.

Could be quite a few good parts on there though.

I'd say the chassis is rotten to the core. Suspect front screen been out a while so lots of rain ingress into the cabin.

Could be quite a few good parts on there though.

Philippe db

Well-Known Member

Poor E9

Rek

Well-Known Member

Strange that it says no identity. The owner might not know it, but it should be available from the chassis number. Its a brave person who takes this on.

Whew - I am always shocked to see that this happens to these cars (and other specific makes and models). I would bet there are numbers on the car somewhere (firewall, door sticker, engine block). But at the very least, seems to be a handful of parts that might be usable for a needy chassis?

ya think?

Ya, you can pour $150k into it, but one would be crazy.

Ya, you can pour $150k into it, but one would be crazy.

Rek

Well-Known Member

Just what is restoring a car now?

Does it involve handing the car over to a business, throwing money at them, visiting now and again to moan about stuff and then pick the colours? If that's the case then you're no more 'restoring a car' any more than your are 'making a suit' if you commision one from a tailor.

That is also how you would throw $150,000 at this car.

My car has cost me £40-£45k including the purchase price of it and the donor car for the engine and some other parts. It's not perfect but anything wrong will be corrected over time, and on a cost efficient business. When I first posted on this forum, the number of posts from members saying that I was mad and should sell it for parts was intense. That made me more determined and I used a good body shop guy and a host of other suppliers as well as doing a lot of the work myself.

Someone should bite the bullet and be determined enough to bring this back from the dead. If so, don't spend $150,000 but be brave and do the planning and some of the work yourself. Source the parts as cleverly as you can and be part of the project, not just the "money". That way you will pay less and enjoy the reward of being fully involved.

Does it involve handing the car over to a business, throwing money at them, visiting now and again to moan about stuff and then pick the colours? If that's the case then you're no more 'restoring a car' any more than your are 'making a suit' if you commision one from a tailor.

That is also how you would throw $150,000 at this car.

My car has cost me £40-£45k including the purchase price of it and the donor car for the engine and some other parts. It's not perfect but anything wrong will be corrected over time, and on a cost efficient business. When I first posted on this forum, the number of posts from members saying that I was mad and should sell it for parts was intense. That made me more determined and I used a good body shop guy and a host of other suppliers as well as doing a lot of the work myself.

Someone should bite the bullet and be determined enough to bring this back from the dead. If so, don't spend $150,000 but be brave and do the planning and some of the work yourself. Source the parts as cleverly as you can and be part of the project, not just the "money". That way you will pay less and enjoy the reward of being fully involved.

Hi @Rek,

I would love to see and hear some of the updates on your car. I know that you dropped the B9 motor in, but where did you land with metal work? Your purchase thread was quite doom and gloom and you mentioned that you would post pictures once complete. I know that we are never done but I presume that with the figures and references above - you have made some progress. Anything you want or are willing to share? I need to do quite a bit of metal work on my car, and plan to start just after the holidays.

I would love to see and hear some of the updates on your car. I know that you dropped the B9 motor in, but where did you land with metal work? Your purchase thread was quite doom and gloom and you mentioned that you would post pictures once complete. I know that we are never done but I presume that with the figures and references above - you have made some progress. Anything you want or are willing to share? I need to do quite a bit of metal work on my car, and plan to start just after the holidays.

Last edited:

Rek

Well-Known Member

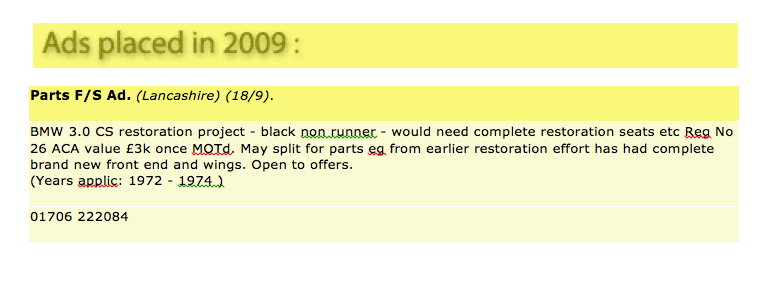

Before buying the car, I searched the web for the registration number. I found this, and an inspection with a camera confirmed it. This was not the current owner so he might not have known about it. Not a great front end rebuild though, but something I could use until I could have a better job done.

Rek

Well-Known Member

Hi @Rek,

I would love to see and hear some of the updates on your car. I know that you dropped the B9 motor in, but where did you land with metal work? Your purchase thread was quite doom and gloom and you mentioned that you would post pictures once complete. I know that we are never done but I presume that with the figures and references above - you have made some progress. Anything you want or are willing to share? I need to do quite a bit of metal work on my car, and plan to start just after the holidays.

My car currently looks like this. If anyone would like to know what was done and how, I am happy to share but there are so many pictures of the same rebuild here I did not want to post yet another picture of sills/rockers being replaced. I know its not perfect as the front wheels sit slightly further back in the wheels wells than they should but it's hardly noticeable nd the whole thing is straight.

mr bump

Well-Known Member

Very nice rims, 17” staggered?My car currently looks like this. If anyone would like to know what was done and how, I am happy to share but there are so many pictures of the same rebuild here I did not want to post yet another picture of sills/rockers being replaced. I know its not perfect as the front wheels sit slightly further back in the wheels wells than they should but it's hardly noticeable nd the whole thing is straight.

View attachment 57188

Rek

Well-Known Member

Metalwork completed:

Still to do:

Inspection around windows. This will happen when screens replaced and before second spraying.

At some point a new boot/trunk lid.

Thats just the metalwork though. There is still lots to do but my bodywork guy lost his shop and is emigrating to Cyprus.

The wheels are from the Alpina donor, or at least the rears are - 9.5" and the fronts are B10 Alpina winter wheels at 8" for the correct ET and clearance.

Staggered? Yes - by the price of the front wheels from Alpina.

- Wings/fenders off and blasted to inspect the rebuild - no rust but a small hole. Shoddy welding but stable and correct measurements, so rustproofed and replaced wings.

- New floors both sides, front and back

- New inner, middle and outer sills, both sides (rockers?)

- New frame rails both sides - extended to rear and tied to rear subframe mounts. Original design stopped half way to the rear of the car.

- Replace metal on lower parts of A pillar, B pillar and between the rear wheel well and the B pillar.

- Bonnet/hood blasted, rustproofed and re fitted.

- Boot/trunk lid blasted rust proofed and re fitted.

- Doors removed and blasted - one door skin replaced - dubious measurements or workmanship.

- Replaced rear seat mount sheet steel with 1" 2.5mm thickness steel section; much stiffer.

- Repair section around inner rear wheel arch and outer section.

- ALL outer surface paint/underseal flayed clear to bare metal and surface prepped for paint.

Still to do:

Inspection around windows. This will happen when screens replaced and before second spraying.

At some point a new boot/trunk lid.

Thats just the metalwork though. There is still lots to do but my bodywork guy lost his shop and is emigrating to Cyprus.

The wheels are from the Alpina donor, or at least the rears are - 9.5" and the fronts are B10 Alpina winter wheels at 8" for the correct ET and clearance.

Staggered? Yes - by the price of the front wheels from Alpina.

Love your play on the word "staggered." Something we have all been experiencing on the price of e9 parts.Metalwork completed:

I used flaying rather than blasting or acid dipping. I tried dry ice blasting for one day but it was not effective, expensive and the operator needed to dress up as an astronaut.

- Wings/fenders off and blasted to inspect the rebuild - no rust but a small hole. Shoddy welding but stable and correct measurements, so rustproofed and replaced wings.

- New floors both sides, front and back

- New inner, middle and outer sills, both sides (rockers?)

- New frame rails both sides - extended to rear and tied to rear subframe mounts. Original design stopped half way to the rear of the car.

- Replace metal on lower parts of A pillar, B pillar and between the rear wheel well and the B pillar.

- Bonnet/hood blasted, rustproofed and re fitted.

- Boot/trunk lid blasted rust proofed and re fitted.

- Doors removed and blasted - one door skin replaced - dubious measurements or workmanship.

- Replaced rear seat mount sheet steel with 1" 2.5mm thickness steel section; much stiffer.

- Repair section around inner rear wheel arch and outer section.

- ALL outer surface paint/underseal flayed clear to bare metal and surface prepped for paint.

Still to do:

Inspection around windows. This will happen when screens replaced and before second spraying.

At some point a new boot/trunk lid.

Thats just the metalwork though. There is still lots to do but my bodywork guy lost his shop and is emigrating to Cyprus.

The wheels are from the Alpina donor, or at least the rears are - 9.5" and the fronts are B10 Alpina winter wheels at 8" for the correct ET and clearance.

Staggered? Yes - by the price of the front wheels from Alpina.

Rek

Well-Known Member

If the values of the car go up, then so do the spares. I have half a garage full but I am waiting until I can buy a Faberge Egg with the proceeds.

mr bump

Well-Known Member

Rek, we use the term staggered for sizes, 8.5” & 9.5” for example is the original rims on my E34 B10 so a staggered set. You’ve never heard the term?

Mr. Bump, not since my drag racing, hot rod, 57 Chevy days in my errant youth. the late 50s, early 60s. And let us not forget the unforgettable "Stagger Lee" by the late, great Lloyd Price.Rek, we use the term staggered for sizes, 8.5” & 9.5” for example is the original rims on my E34 B10 so a staggered set. You’ve never heard the term?

Steve

Rek

Well-Known Member

Rek, we use the term staggered for sizes, 8.5” & 9.5” for example is the original rims on my E34 B10 so a staggered set. You’ve never heard the term?

Yes. It was a play on the word.

My 8.5” would not fit so I needed 8” snow wheels from Alpina. Different ET so that snow chains could fit. They made them especially for the E34 B10 and it took me a while to work out what was needed and then to locate a pair.