First, you might want to review this thread that discusses excessive engine movement.

https://e9coupe.com/forum/threads/excessive-engine-movement.29378/

Unclear exactly what or how or why you reinforced the prop shaft bearing with polyurethane. Since you reference "bearing," does that mean you added polyurethane around the rubber center support bearing? Perhaps you over did it, so that the support has become so stiff as to defeat the very purpose of the compliant/flexible rubber support? Curious whether you installed the original equipment donut giubo, the later/thinner laminated frisbee version or an ultra-stiff aftermarket urethane version.

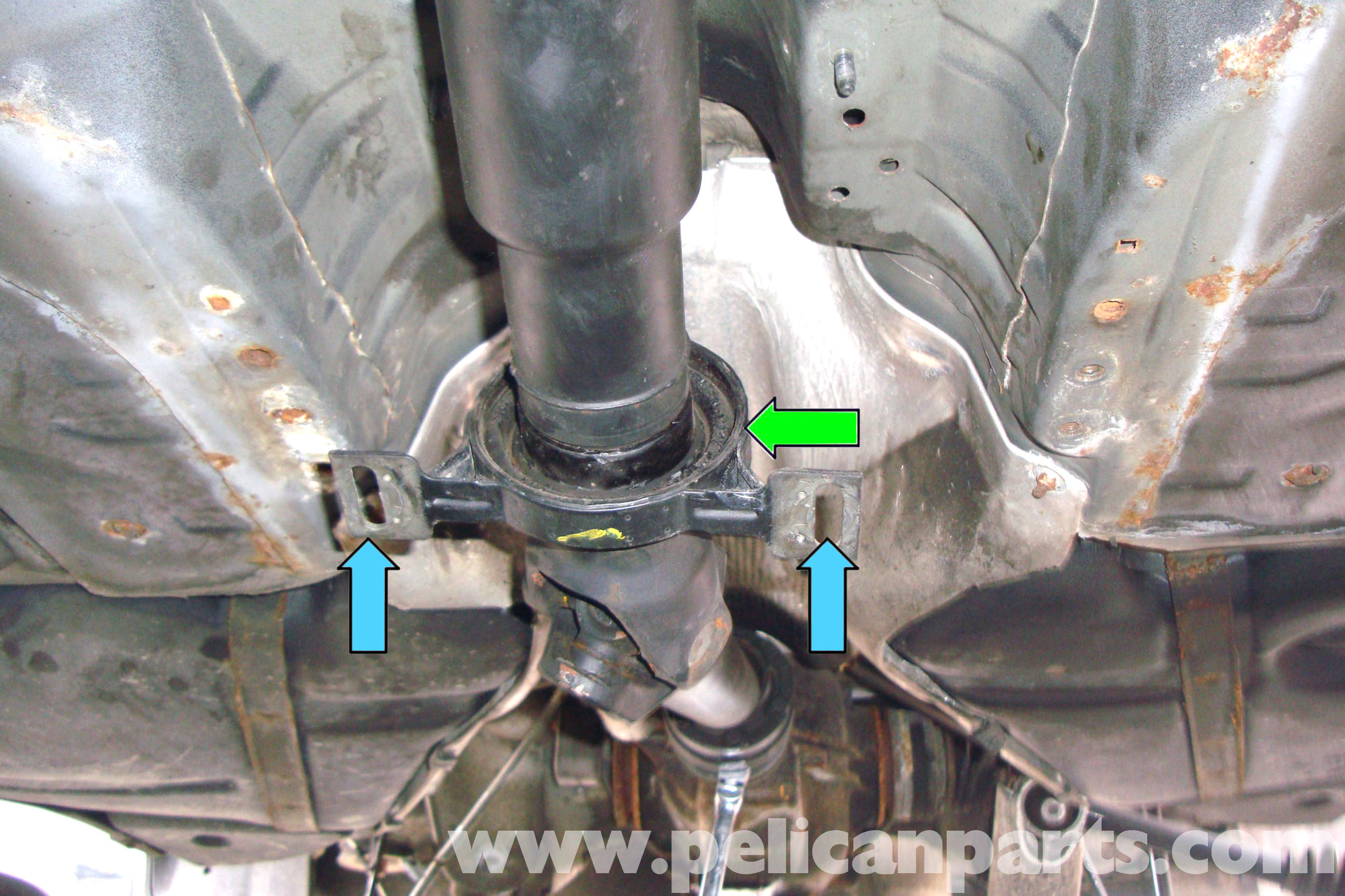

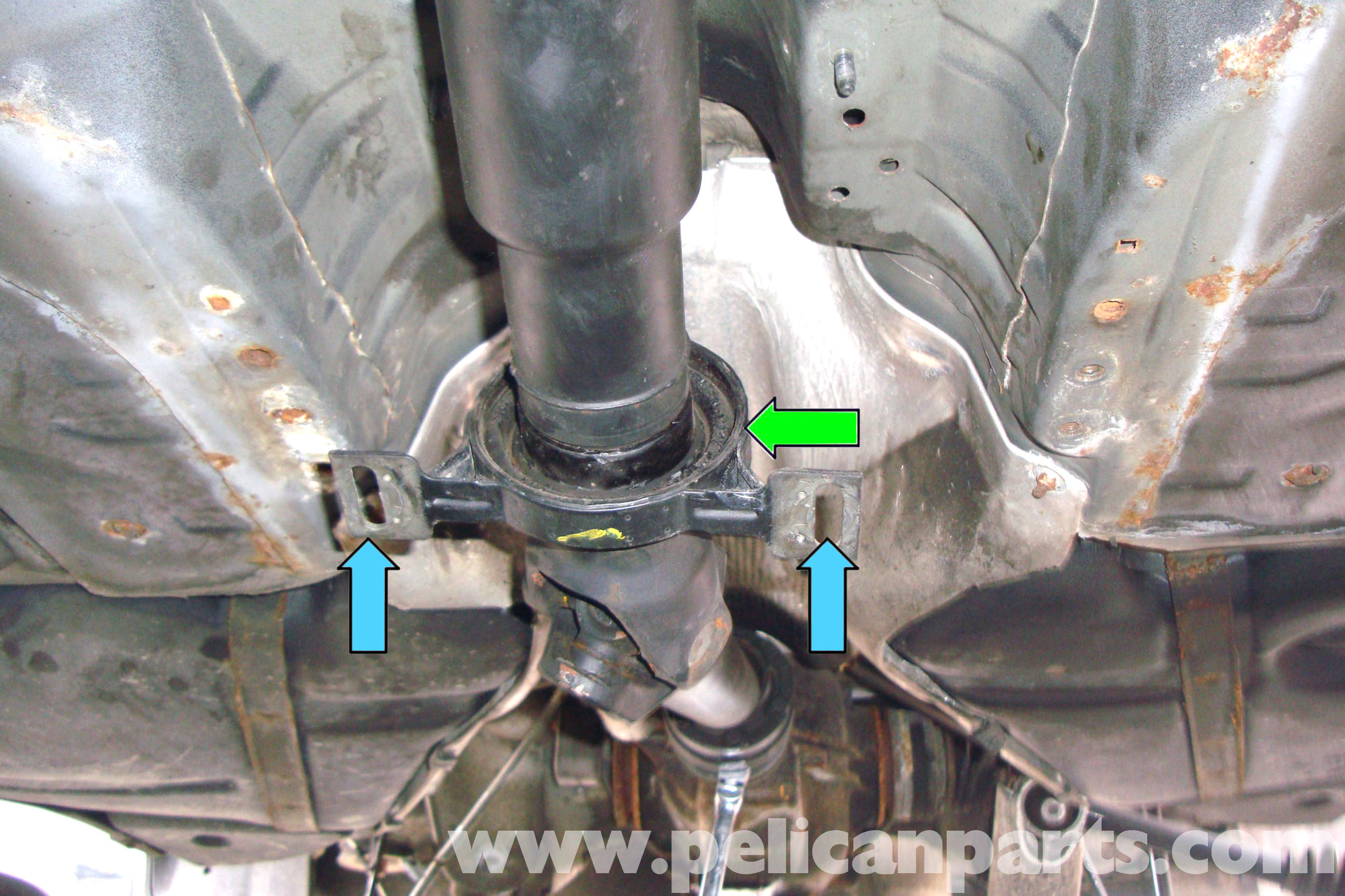

My experience with polyurethane/delrin motor mounts is limited. While they were originally chosen to limit engine movement, they transmitted too much vibration to the cabin for a street-driven vehicle. This was on standard unmodified 4speed equipment. In addition to being uncomfortable for vehicle occupants, the unwanted vibration created a concern for overstressing various body welds - potentially causing more problems/noises than avoiding them. One supposes that the results might have been different if the engine mounts were rubber and the cross member/transmission support was polyurethane or vice versa. Urethane mounts have been available in different stress-strain properties, but I do not recall which versions we tried. Further, regarding the transmission support cross member, I have observed a number of situations where the rubber transmission mount had deteriorated but vehicle occupants might not notice this except for when the vehicle is driven vigorously: "Thump" "Bang"

Other than the driveshaft alterations to accommodate the five speed's extra length, the one thing that typically differs between original four speed installations and five speed after market installations is the cross member supporting the five speed and its installation. If, for example, the new/modified cross member involves a series of home brewed cantilevered connections, it only takes one or two loose connections to make an unexpected/abnormal noise under stress. Noise might also occur if the cross member is not properly secured to the body. "Thump "Bang" Also, if the gear shifter/platform bushes are sloppy, this may result in unwanted contact with the vehicle's body, especially when the drive train is stressed under significant acceleration/deceleration. Your description of a "big noise" could not only indicate a broken weld, a loose transmission support cross member/worn transmission support bearing - but something as seemingly unrelated as a loose exhaust system contacting the vehicle undercarriage.