Wladek

Well-Known Member

Hello Guys,

this is my first post on this forum, so at first i just want shortly introduce myself - my name is Wladek, i'm from Poland, i have 1972 Fjord CSI for about 1,5 years (in full renovation process).

I'm here with you on forum for about half year - I am very happy that I could join you, because you are great community of very nice and helpful people; and what i think is most important, people who are not expecting anything in return.

I was thinking maybe it will be better to introduce myself with some helpful thread instead of just writing in „Intro”.

So here we are...

I've already made cleaning/disassembling of 4x different sets of E9 rear windows mechanism's. All of them where more or less stucked, because of old grease, after years this grease is more like plastic, than lube, so mechanisms just stucked, thats why pretty often also gear rubbers are broken.

this is my first post on this forum, so at first i just want shortly introduce myself - my name is Wladek, i'm from Poland, i have 1972 Fjord CSI for about 1,5 years (in full renovation process).

I'm here with you on forum for about half year - I am very happy that I could join you, because you are great community of very nice and helpful people; and what i think is most important, people who are not expecting anything in return.

I was thinking maybe it will be better to introduce myself with some helpful thread instead of just writing in „Intro”.

So here we are...

I've already made cleaning/disassembling of 4x different sets of E9 rear windows mechanism's. All of them where more or less stucked, because of old grease, after years this grease is more like plastic, than lube, so mechanisms just stucked, thats why pretty often also gear rubbers are broken.

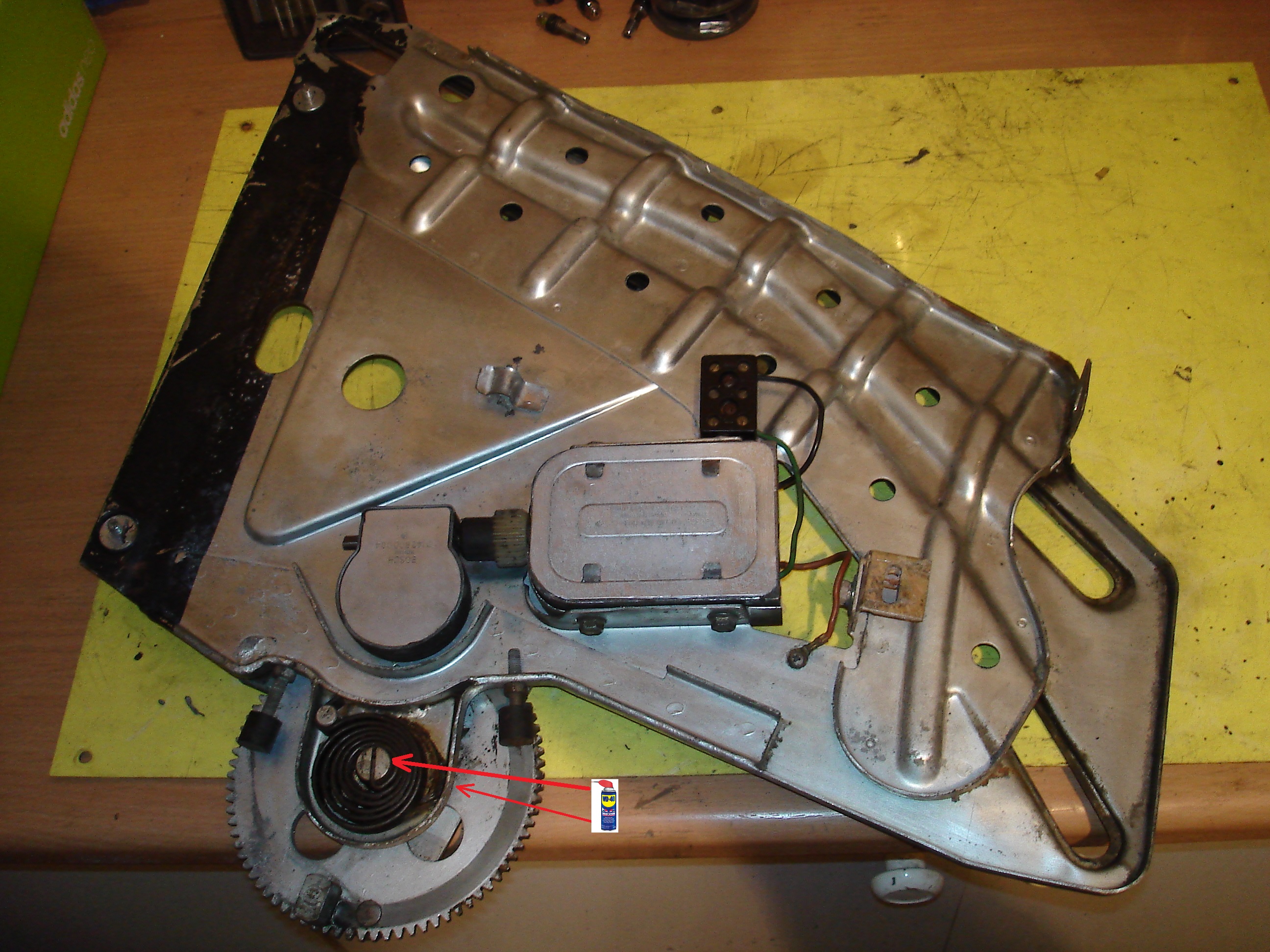

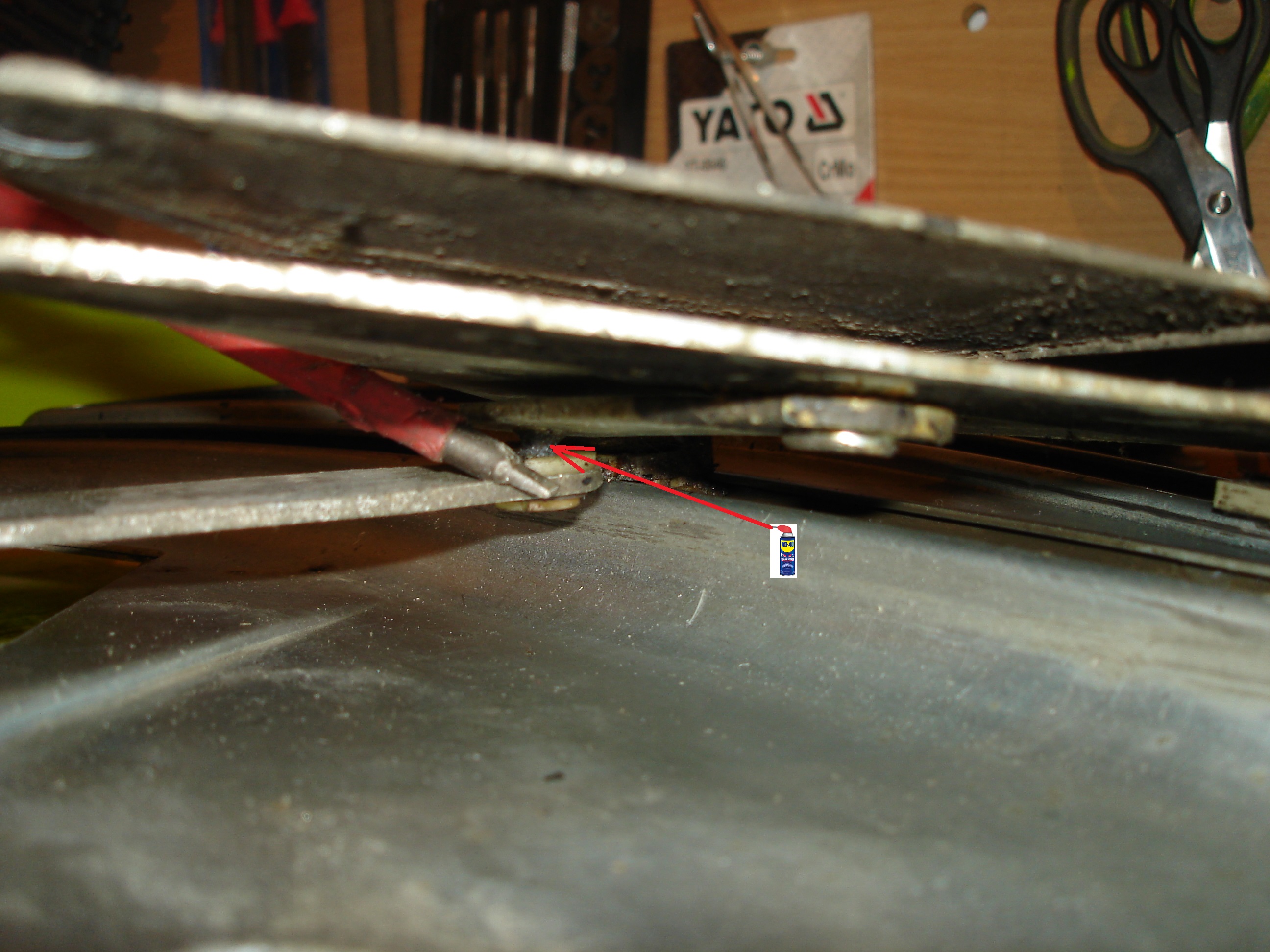

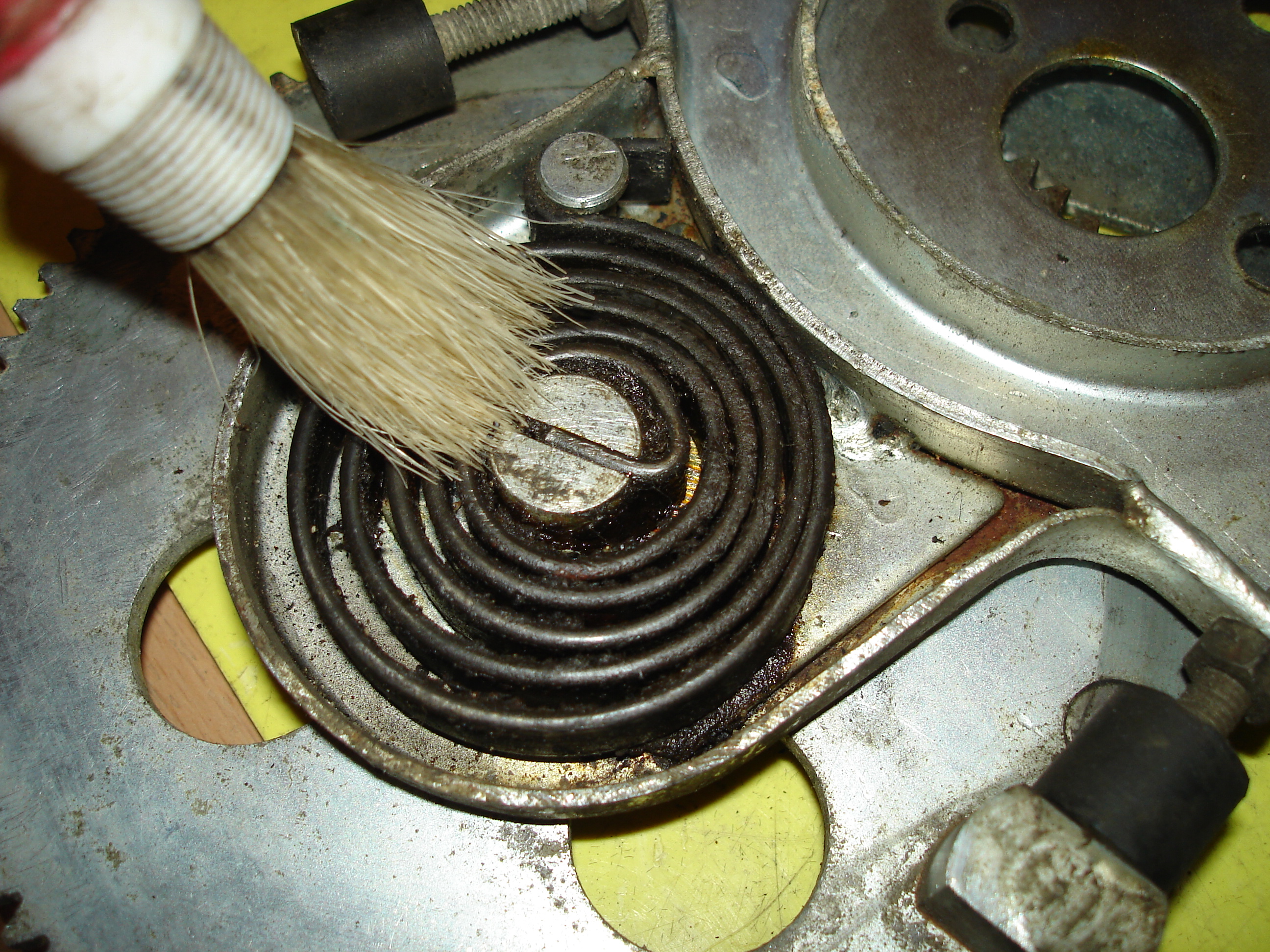

- On the photo below i showed some tools that might be helpful, i didn't show this on photo, but you will also need something like WD40 (because some parts might be stuck like a „rock”, so at first step you just want to soften them).

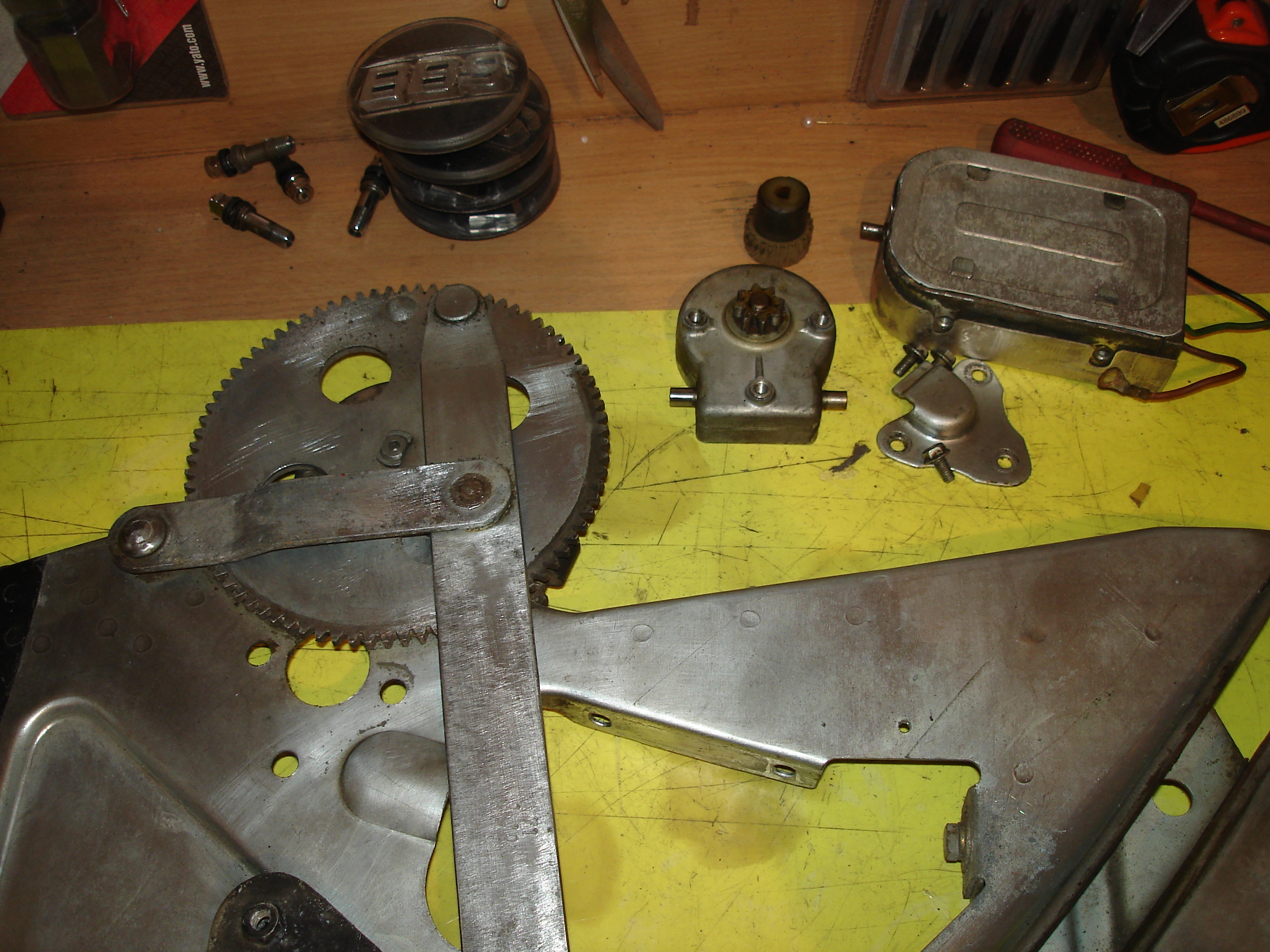

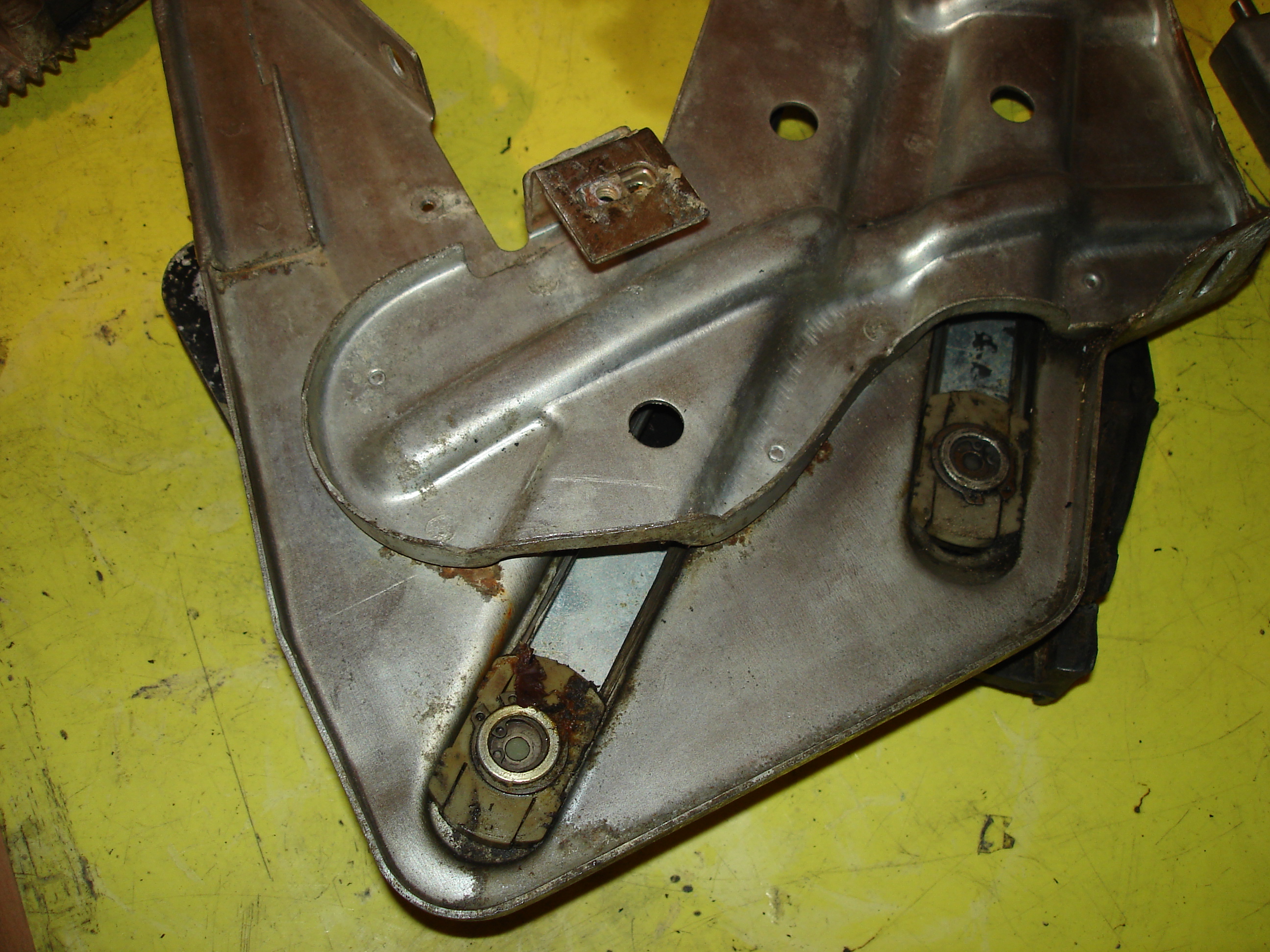

- At this case i showed old type mechanism used till 1973, but the same manual can be use on later style mechanism, the only difference is motor mount (that is even more simple).

- FIRST THING BEFORE YOU START DISASSEMBLY – if you can try to make mechanism go down for at least half way (if outside the car using 12V battery ((+) plus is green or black depends on direction; (-) minus is brown), it will make your work easier on the next levels). If you can't, don't worry it can also be made whithout it, but it will require more work and patience (made it on one of the sets, was fully stucked). You also want to put some WD40 on places i marked on photo's.

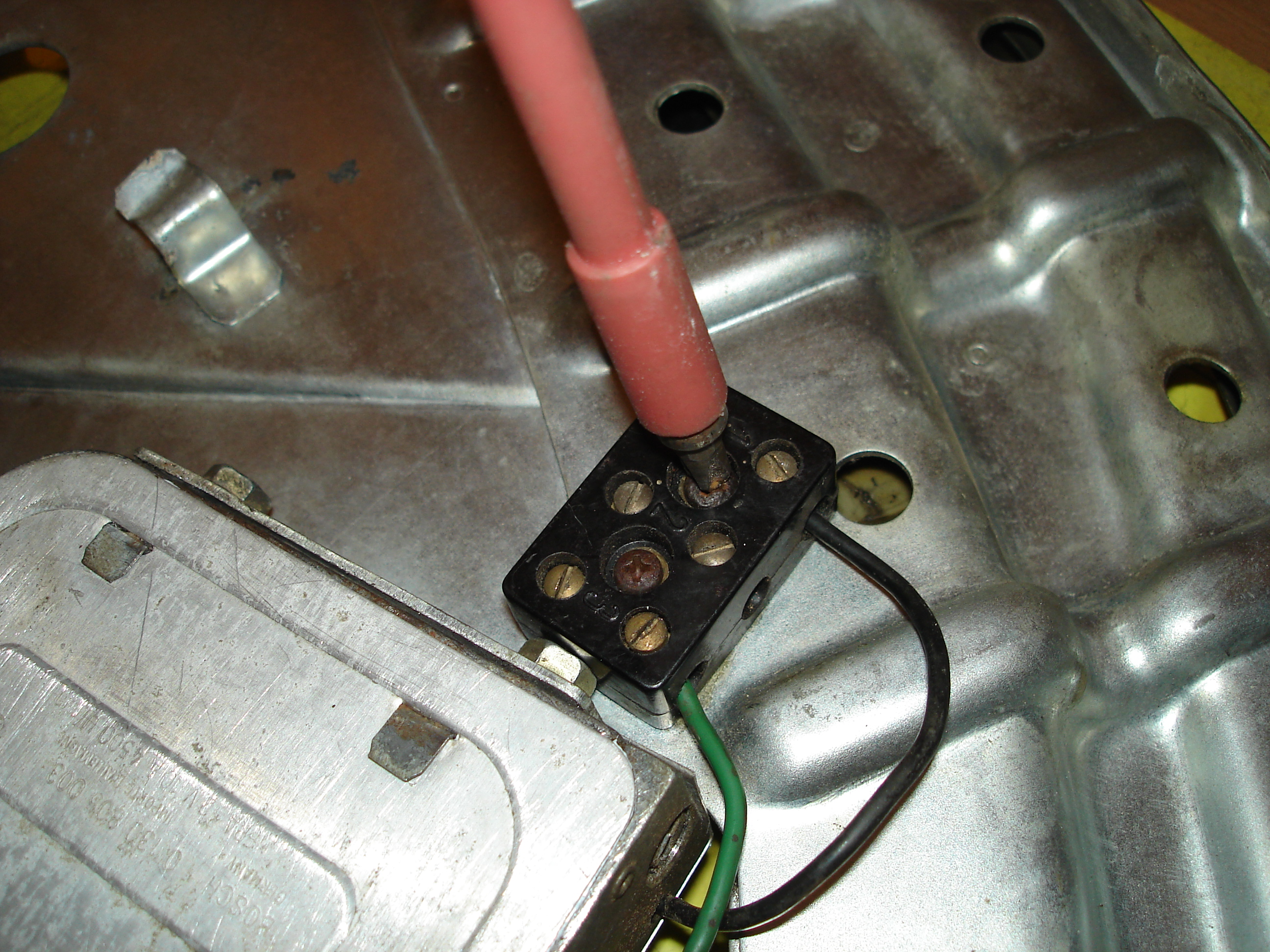

- At first you have to unscrew cable socket (two philips type bolts)

- Unscrew ground wire

- Unscrew four 10mm motor mounting bolts.

- Gently push motor down (as shown on photos), be careful not to brake gear rubber.

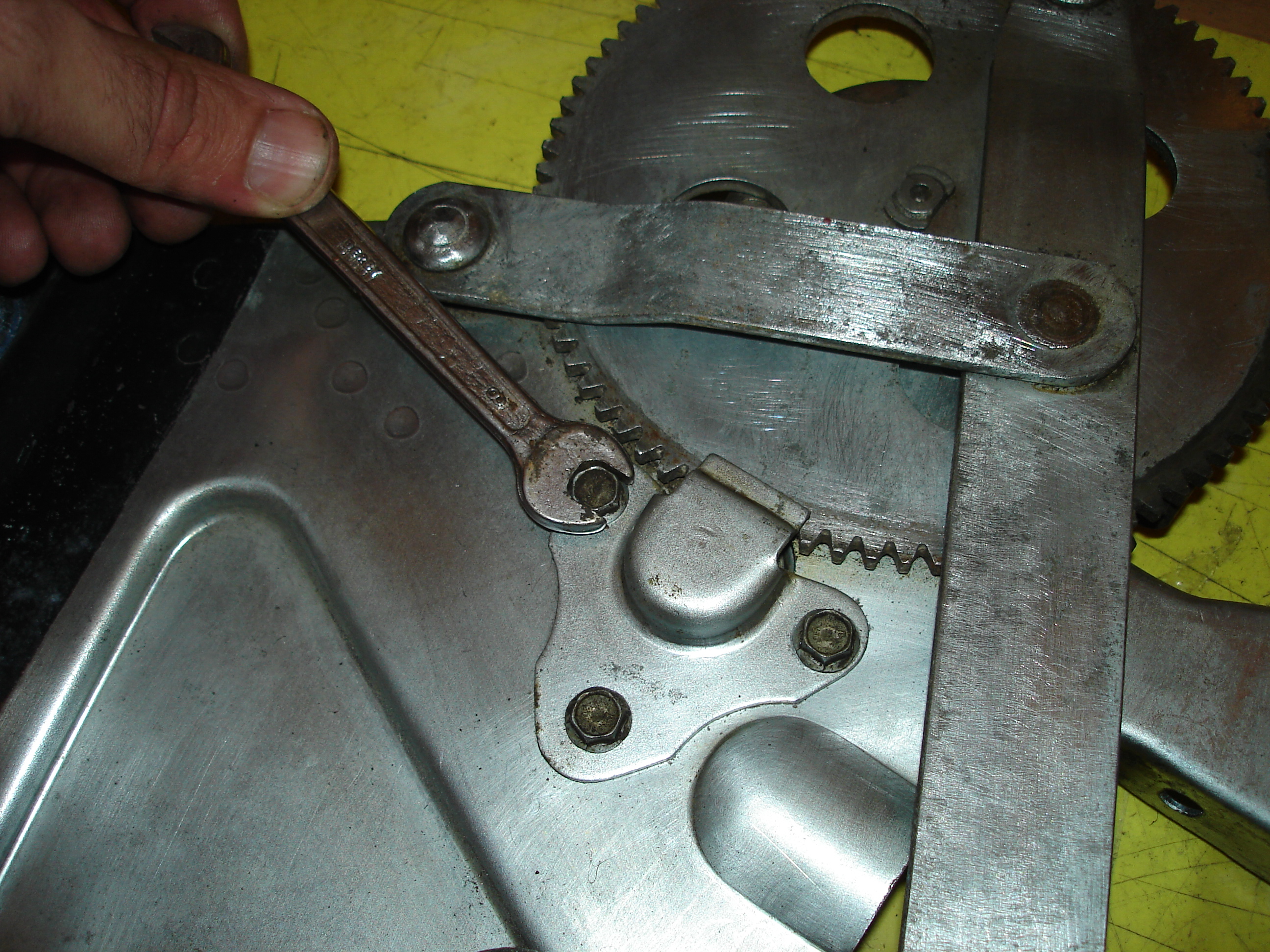

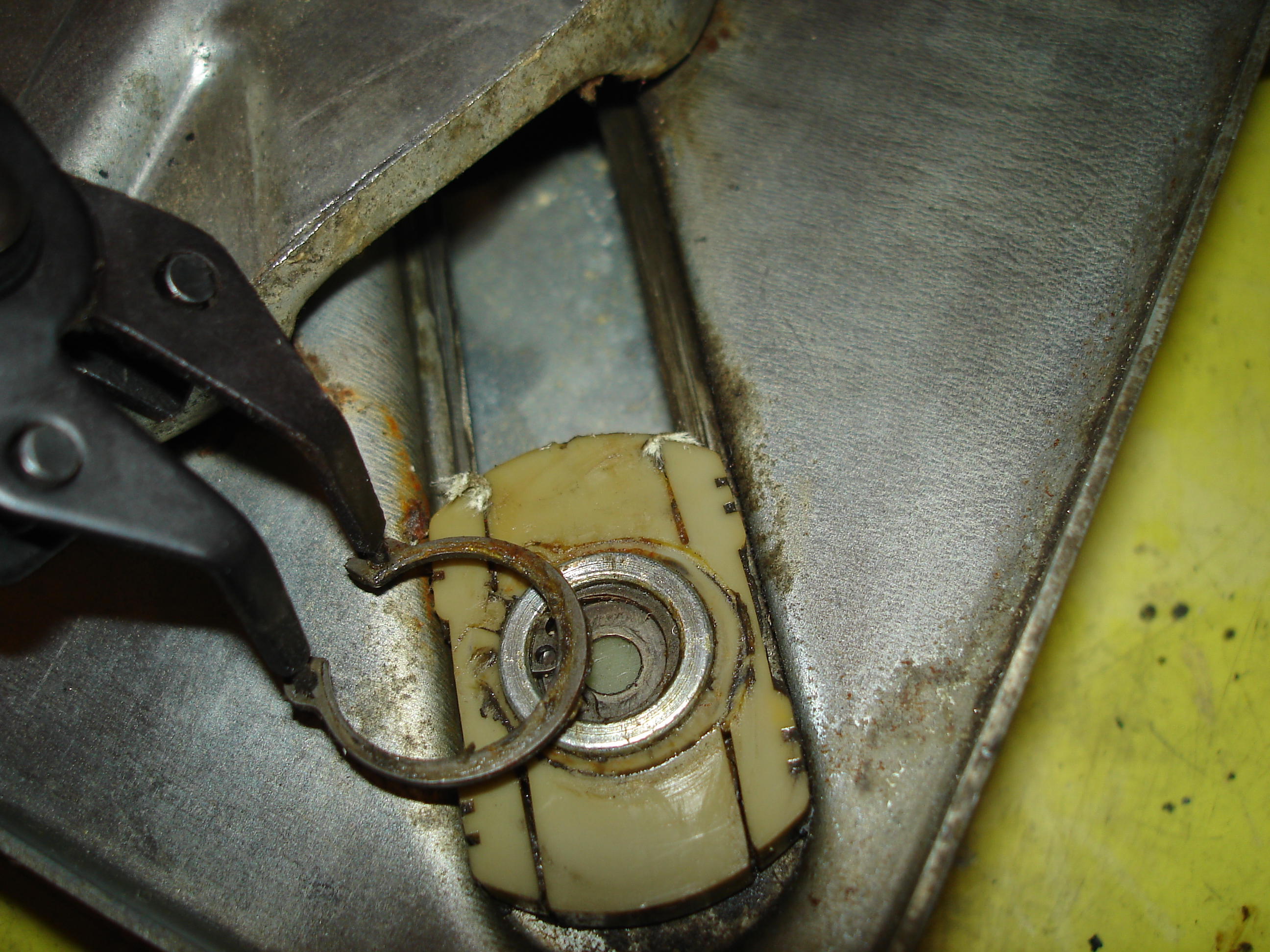

- Now it's time for gear disassembly 3x 8mm bolts – if you pushed down your window as on 3 step, than you just make like me; If not you will need fully flat, short, thin 8mm key, because if window is up - lever will cover the 8mm screws and you will have to unscrew them from above or below with a very small movements to unscrew (but it can be done believe me).

- After gear disassembly time to disassemble window mount from lever. Use big/massive flat screwdriver (bigger is better in this particular situation) – scrape and press as shown on photo, it have just metal ball mount.

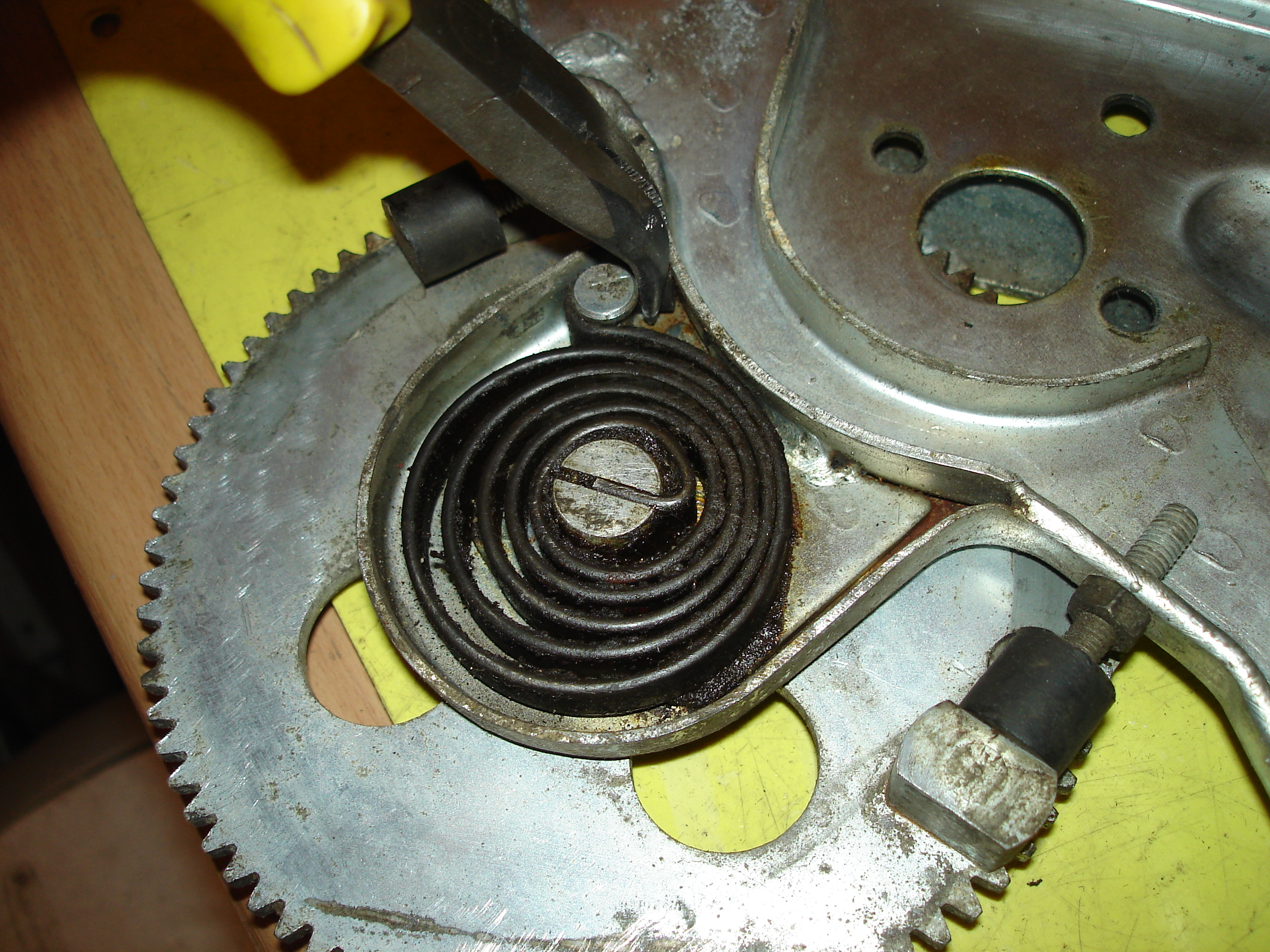

- Lever is free now and can be moved up & down (so you can feel the resistance). On this step you can disassemble spring for perfect cleaning, but if you can't or don't want you don't have to do this and just go for next step.

- After puting extra WD40 on marked places and additional 20-30 up & down movements lever should work a lot more fluent wihout much resistance, if not repeat WD40 and UP & DOWN movements.

Attachments

Last edited: