hi

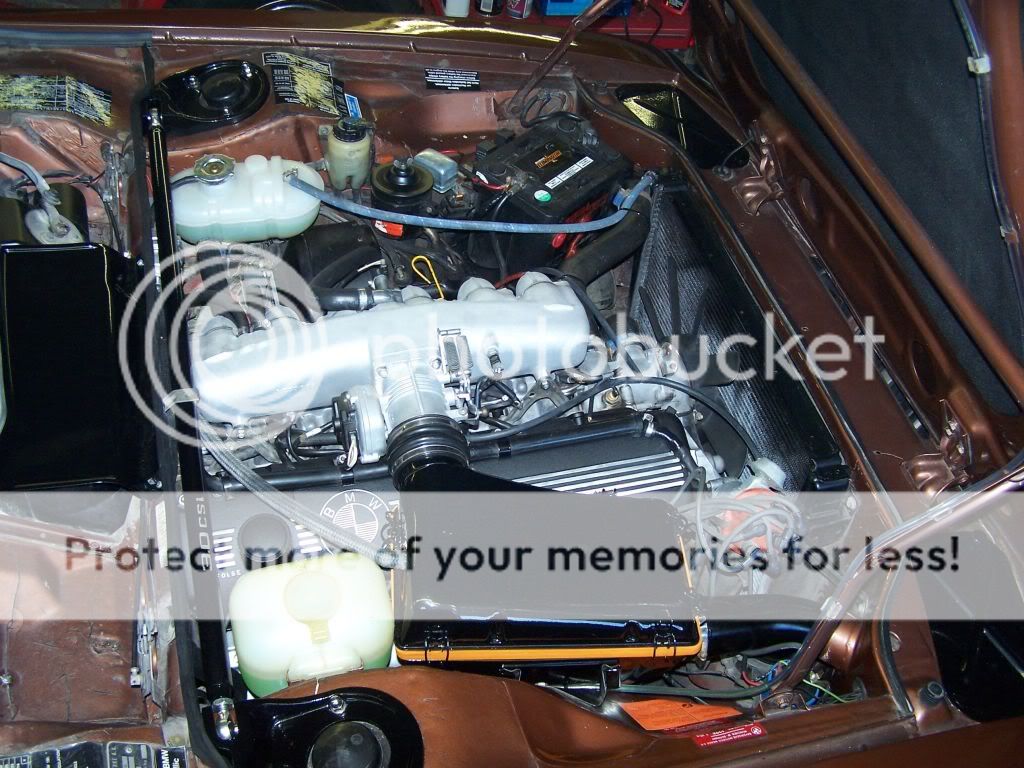

i am sharing with you a minor detailed work of the sheet metal covers that close the hole that give access to the headlamps from the engine compartment

i found those ones in germany, they were very rusty, but considering that they are not structural parts, i will do the following:

start

rust on the backside

take away the old paint with chemicals

white paint under the red one, repeat process

machine sanding, and rust converter

first paint: primer, see the holes, not very big

considering i am not an expert in welding or other skills to do it in a professional way, and also taken into account the size of the holes, i decided to put adhesive tape as a "moulding" to give the needed continuity to the shape, in order to pour special metallic compount (epoxi based), from the other side

to be continued

i am sharing with you a minor detailed work of the sheet metal covers that close the hole that give access to the headlamps from the engine compartment

i found those ones in germany, they were very rusty, but considering that they are not structural parts, i will do the following:

start

rust on the backside

take away the old paint with chemicals

white paint under the red one, repeat process

machine sanding, and rust converter

first paint: primer, see the holes, not very big

considering i am not an expert in welding or other skills to do it in a professional way, and also taken into account the size of the holes, i decided to put adhesive tape as a "moulding" to give the needed continuity to the shape, in order to pour special metallic compount (epoxi based), from the other side

to be continued