I have finished my under carraige projects (a/c drain hole upgrade, new tranny seals, new center bearing, caliper/exhaust/manifold painting, and some frame/differential detailing) and want to clean up the clutch slave before tranny reinstall but it is frozen on the bell housing - what's the trick here - wood piece and hammer or some other barbaric technique? It didn't respond to my first overtures with the hammer so before I pull out bigger weapons I ask here. Also, the rod that pushes the clutch fork came out, is this supposed to happen or does it mean it's shot inside? Thanks.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

stuck clutch slave cylinder

- Thread starter Stevehose

- Start date

JhwShark

Well-Known Member

Steve,

Try spraying PB Blaster on it at the join from both sides. Let it soak overnight and spray again and wait a couple of hours. Did you remove the retainer??

I believe, if the rod came out you need to rebuild. What came out with it?

Jon

Try spraying PB Blaster on it at the join from both sides. Let it soak overnight and spray again and wait a couple of hours. Did you remove the retainer??

I believe, if the rod came out you need to rebuild. What came out with it?

Jon

It's been soaking in penetrant since sunday with daily blasts. The retaining ring is off as is the boot. Some brake fluid was in the boot but it doesnt appear to be leaking. Is a rebuild kit available? I saw a post where Double 02 might have something? The usual sites tell me NLA which means I am SOL as new ones are $$$.

Steve,

Try spraying PB Blaster on it at the join from both sides. Let it soak overnight and spray again and wait a couple of hours. Did you remove the retainer??

I believe, if the rod came out you need to rebuild. What came out with it?

Jon

I can't get the circlips in a place to rotate that and get it off, will try to again. Meanwhile I have found this part number:

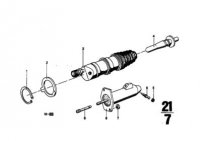

21521103191 which appears to be a rebuild kit NLA, is this easy to repair - Looks like a couple seals and washers. Mine looks like the top one in the attached pic which I believe is 22mm

21521103191 which appears to be a rebuild kit NLA, is this easy to repair - Looks like a couple seals and washers. Mine looks like the top one in the attached pic which I believe is 22mm

Did you pull the little plug- the anti- rotational device in the key way? then try rotating till it's free?

Measure the bore- 22mm?

Attachments

Last edited:

The circlips are just locks. They have to come off. Stick a screwdriver in between the circlip tangs and twist to loosen a bit.if you don't have circlip pliers then you've got to get creative with finish nails stuck in the holes, a screwdriver, and a pair of needle nose. Then take it off. Then it should rotate a bit to break the rust.

A rebuild kit is easy. Check the bore. Use a VW brake hone tool in brake fluid if not clean.

22MM- If need be, cross reference to inches. A parts store ought to be able to cross reference or let me know. That's what I had to do to a Porsche when the kits weren't available just then.

A rebuild kit is easy. Check the bore. Use a VW brake hone tool in brake fluid if not clean.

22MM- If need be, cross reference to inches. A parts store ought to be able to cross reference or let me know. That's what I had to do to a Porsche when the kits weren't available just then.

I have circlip pliers and still couldn't get the front ring off but now that it has soaked for a while i will go back at it tonight with a little more authority. After I get it apart I will measure the seals and get back to you. Thanks much.

The circlips are just locks. They have to come off. Stick a screwdriver in between the circlip tangs and twist to loosen a bit.if you don't have circlip pliers then you've got to get creative with finish nails stuck in the holes, a screwdriver, and a pair of needle nose. Then take it off. Then it should rotate a bit to break the rust.

A rebuild kit is easy. Check the bore. Use a VW brake hone tool in brake fluid if not clean.

22MM- If need be, cross reference to inches. A parts store ought to be able to cross reference or let me know. That's what I had to do to a Porsche when the kits weren't available just then.

Stick a screwdriver between the ears and twist slightly to free the stuck circlip. ( Easy does it here.) Then you can use the circlip pliers.

I've dug them out before with a screwdriver as a last resort. Or preferably broke the rust.

I've dug them out before with a screwdriver as a last resort. Or preferably broke the rust.

jmackro

Well-Known Member

....the clutch slave before tranny reinstall but it is frozen on the bell housing - what's the trick here - wood piece and hammer or some other barbaric technique? It didn't respond to my first overtures with the hammer....

Uh, I wouldn't use any "barbaric technique" at all - you don't want to fracture the loop on the bellhousing. As others recommend (and it sounds like you have already done), use penetrant. Also heat the bellhousing a bit with a torch - the aluminum will expand more than the iron cylinder, increasing the clearance. Try getting it to rotate before trying to press it out. I have used big C clamps to apply consistent pressure, but don't recall if a clamp will fit into an assembled car.

But, go easy with the hammers!

That's why this forum is the best - i didn't think of that. Still working on previous suggestions and will explore the clamp idea. Thanks.

you don't want to fracture the loop on the bellhousing.

The 2002 has the same issue. Destroy the circlips and buy new ones when replacing. Tap on the slave housing on each side with a large flat punch to help release the bonding with the housing. Some have success with large channel lock pliers rotating the slave cylinder, and I like Jay's idea of a really big C clamp.

I've got the same prob right now on my 71 Touring, worst I've encountered in 20 years!

The circlips are there to prevent fore/aft movement, but as you've learned the steel cylinder and alloy housing bore interact with each other and essentially become welded to each other (its called electrolytic action of dissimilar metals) Your discussion here has me somewhat motivated to trying to get the sucker out re-using the tips given here...and the torch heat one as well...I really enjoy that little hauler!

https://s-hphotos-snc4.fbcdn.net/149454_1581409647807_1012677219_31579443_8140064_n.jpg

The circlips are there to prevent fore/aft movement, but as you've learned the steel cylinder and alloy housing bore interact with each other and essentially become welded to each other (its called electrolytic action of dissimilar metals) Your discussion here has me somewhat motivated to trying to get the sucker out re-using the tips given here...and the torch heat one as well...I really enjoy that little hauler!

https://s-hphotos-snc4.fbcdn.net/149454_1581409647807_1012677219_31579443_8140064_n.jpg

P.S. Really, Really, Stuck

Courtesy of the 2002 Boys,

"Date: 5-12-07 07:41

From: Carlos

Subject: Re: Slave cylinder really stuck, grrrrrrrrrrrr

I performed this task on a 6cyl over a very cold March weekend. I banged with a small sledge and a punch to no avail. I ultimately succeeded by using a version of JonA's suggested method: I oiled and twisted with a medium pair of channel lock pliers and a large pair of vice grips. Hit Vice Grips with hammer and off she slid! I rebuild the slave and took a file to all the raised teeth marks and she has been working fine ever since.

I think both of the earlier suggestions are good, although I was afraid of using heat from a flame because of the strong aroma of petrol under the car. (Turned out to be a split fuel line!)

Good luck."

Personal approach- get the circlips off. In that groove on the engine side, wedge a screwdriver or suitable instrument of war and wedge it out.( Like a pickle fork action)

Courtesy of the 2002 Boys,

"Date: 5-12-07 07:41

From: Carlos

Subject: Re: Slave cylinder really stuck, grrrrrrrrrrrr

I performed this task on a 6cyl over a very cold March weekend. I banged with a small sledge and a punch to no avail. I ultimately succeeded by using a version of JonA's suggested method: I oiled and twisted with a medium pair of channel lock pliers and a large pair of vice grips. Hit Vice Grips with hammer and off she slid! I rebuild the slave and took a file to all the raised teeth marks and she has been working fine ever since.

I think both of the earlier suggestions are good, although I was afraid of using heat from a flame because of the strong aroma of petrol under the car. (Turned out to be a split fuel line!)

Good luck."

Personal approach- get the circlips off. In that groove on the engine side, wedge a screwdriver or suitable instrument of war and wedge it out.( Like a pickle fork action)

dp,

Where was the photo of your Touring taken?

Where was the photo of your Touring taken?

dp,

Where was the photo of your Touring taken?

East of Banning on Highway 10....California San Jacinto Mountains

Thx, thought I recognized that couloir in the background.

Chris

Chris

Stunning - looks like the Alps. What's in the back seat, boxes of parts? :mrgreen:

East of Banning on Highway 10....California San Jacinto Mountains

YUP...boxes o' spares that came with the car when I bought it.Stunning - looks like the Alps. What's in the back seat, boxes of parts? :mrgreen:

It was a LOVELY drive through CA starting in Sacramento, hung out for a week or so in the yay area, then down to SoCal for a few days before heading out to West Phoenix (lovely in February) and eventually heading east to Albuquerque before heading north up to Boulder County Colorado. Trips like that can include gorgeous scenery with a little planning and are one of my favorite parts of scoring a new toy...and that 1800 mile trip with some around town time at each stop was a great opportunity to shake the car out and marvel at just how different a touring can be!

now...I just need to get that damn slave cylinder out....well, maybe its time for a 5-spd....

I'm still trying. Last night I managed to get the vice grips on it and after much pounding, freed it from its time-weld. But it only will turn now and is not wanting to come out, it feels like it is pressed in there like a bearing - serious metal to metal bond over 40 years. I juiced it with more penetrant and literally worked it back and forth for 20 min before calling it a night. So i left it to soak more.

Sidenote and future warning: Judging by how stuck this is, like Jay M said earlier, if I hit it hard enough the bell housing ear definitely would have broken before this was free.

Sidenote and future warning: Judging by how stuck this is, like Jay M said earlier, if I hit it hard enough the bell housing ear definitely would have broken before this was free.

now...I just need to get that damn slave cylinder out....well, maybe its time for a 5-spd....

Last edited:

JhwShark

Well-Known Member

Steve,

Given the issue of getting the slave out...Have you considered trying to just rebuild the inner components of it. Replacing the seals and clips on the rod while the rod is out and trying to hone the cylinder then installing the rod and clips...then the boot??

I seem to recall doing something like that on a 2002 in the 80's...memory is not that good, might have had the tranny out...would the release lever be in the way of the hone, if tranny is out can you move the release lever??

Given the issue of getting the slave out...Have you considered trying to just rebuild the inner components of it. Replacing the seals and clips on the rod while the rod is out and trying to hone the cylinder then installing the rod and clips...then the boot??

I seem to recall doing something like that on a 2002 in the 80's...memory is not that good, might have had the tranny out...would the release lever be in the way of the hone, if tranny is out can you move the release lever??