I am moving this thread out of the Classifieds section now that it has turned into more of a project than a WTB.

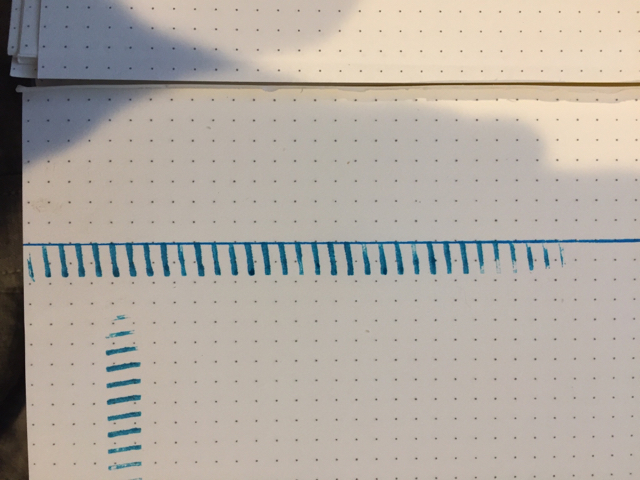

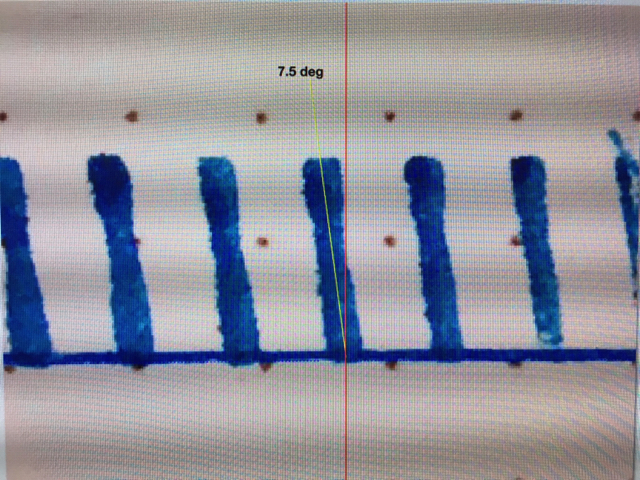

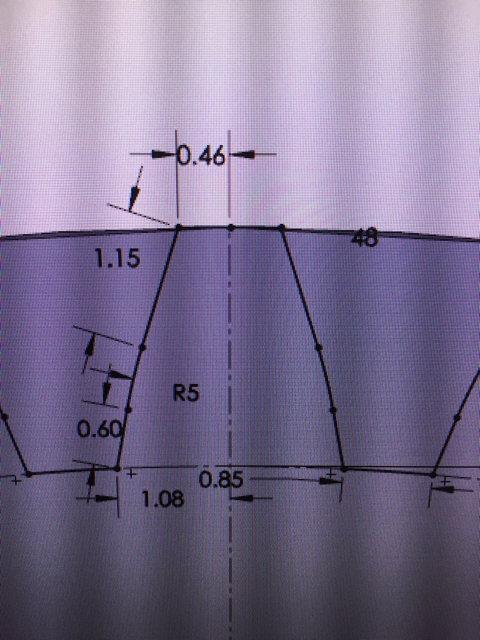

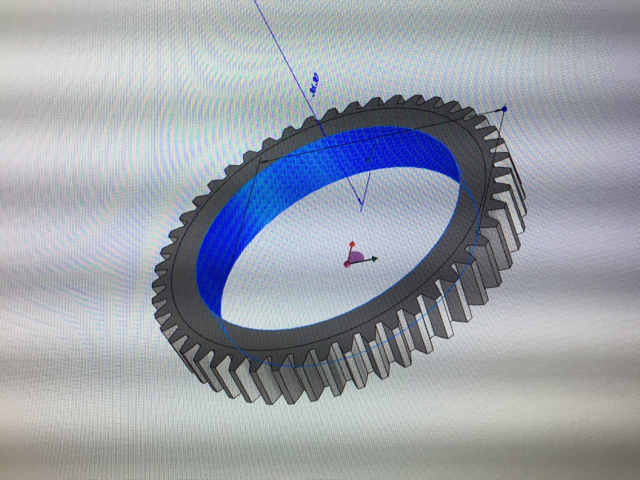

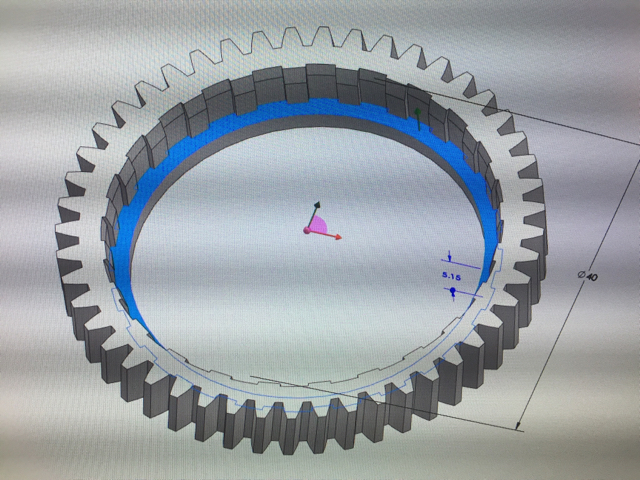

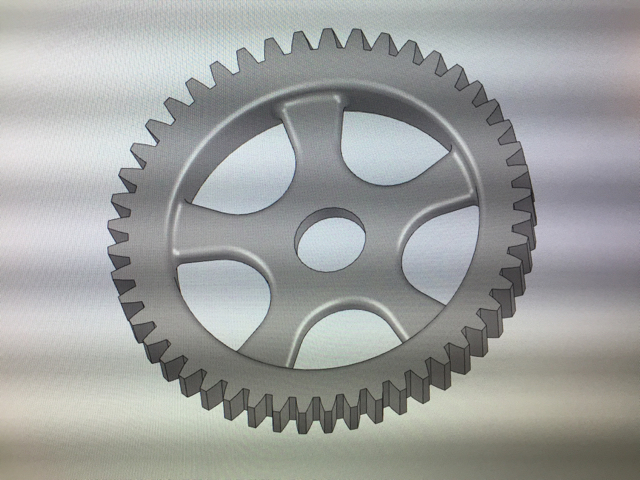

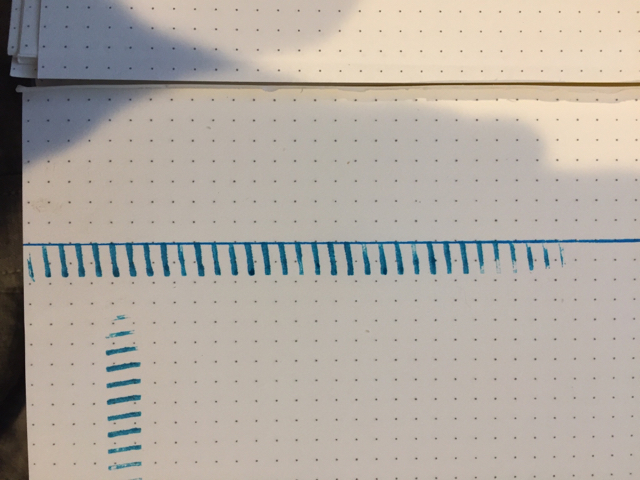

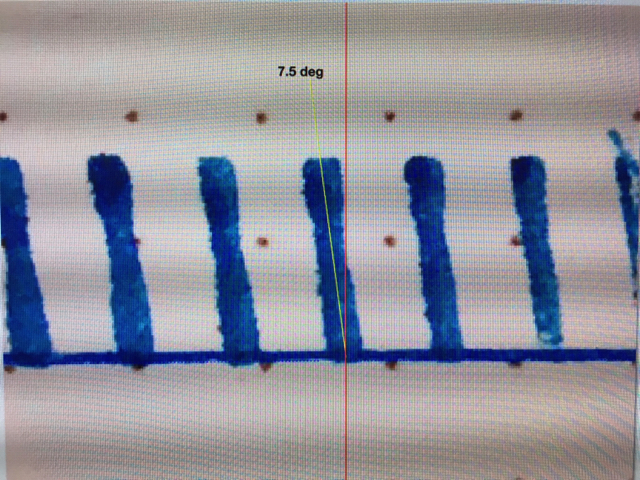

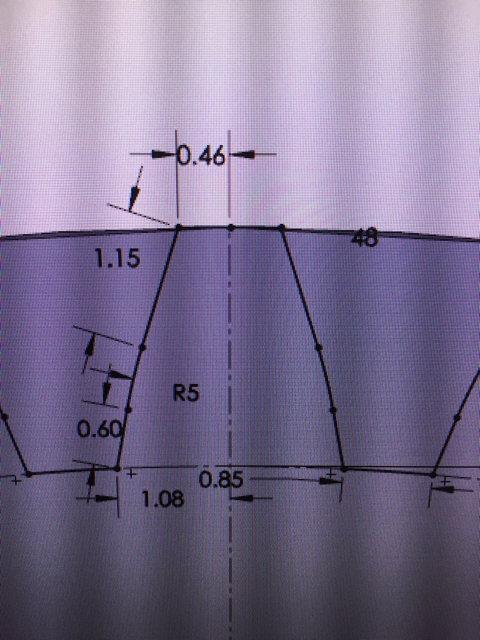

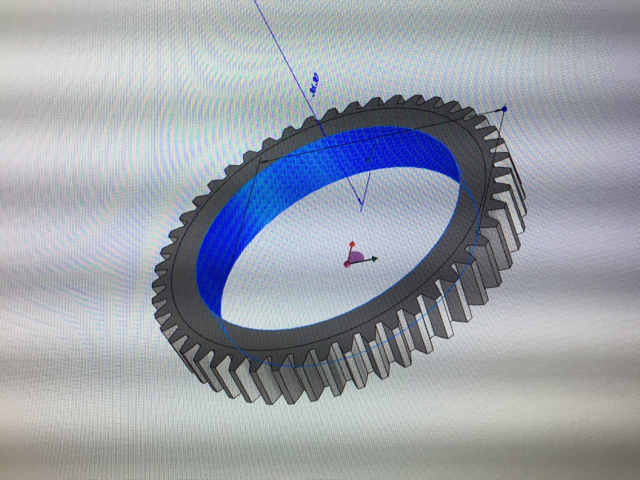

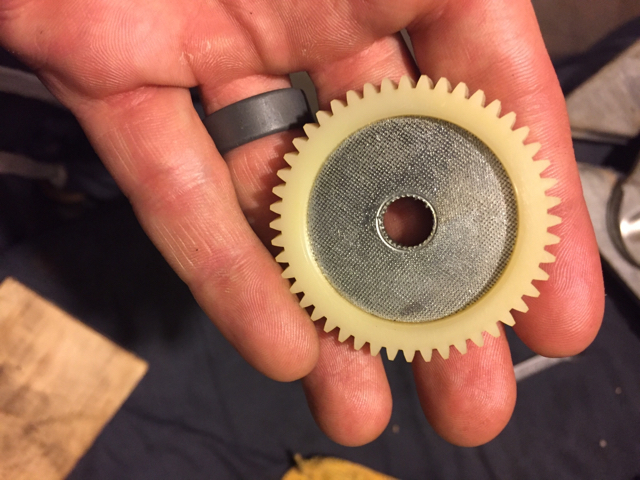

I got the gear out of the transmission last night and started modeling it in SolidWorks this morning.

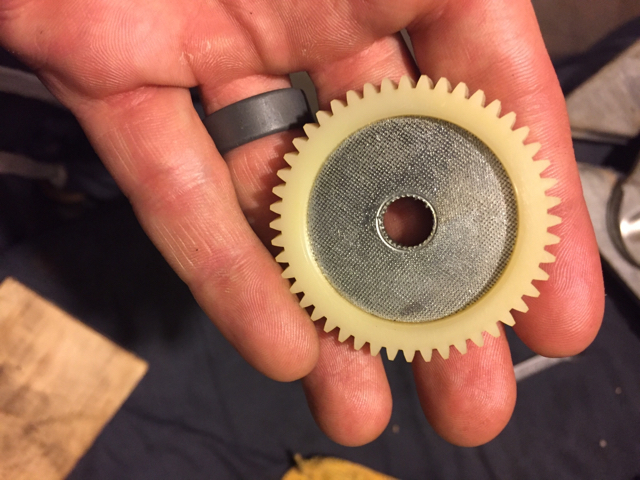

I had though this gear was going to be stripped, but it turned out to be perfectly fine.

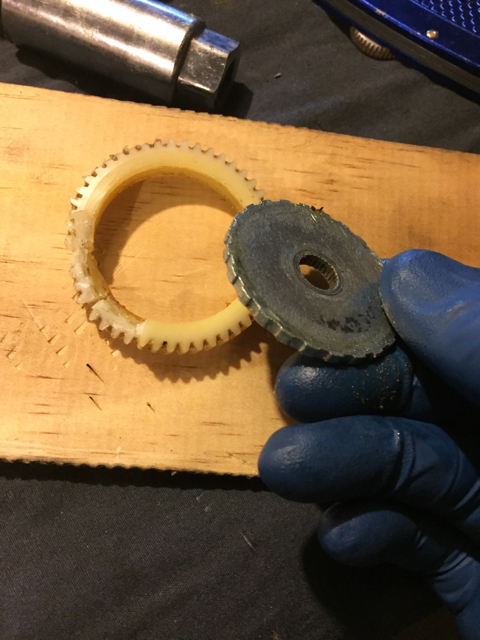

That allowed me to get accurate measurements from a good part, but now I don't want to cut the plastic off of the metal core it is overmolded to. Once I get my hands on a stripped part, (Andrew W. is very kindly sending one) I can cut it apart and measure the features on the inner part. Then I'll cut the reverse of those out of my 3-D model so the two parts can be mated together.

Here's some of the process and where I stand with the 3D model:

I got the gear out of the transmission last night and started modeling it in SolidWorks this morning.

I had though this gear was going to be stripped, but it turned out to be perfectly fine.

That allowed me to get accurate measurements from a good part, but now I don't want to cut the plastic off of the metal core it is overmolded to. Once I get my hands on a stripped part, (Andrew W. is very kindly sending one) I can cut it apart and measure the features on the inner part. Then I'll cut the reverse of those out of my 3-D model so the two parts can be mated together.

Here's some of the process and where I stand with the 3D model: