Ok this may seem obvious to some people, but it was my first time getting parts zinc plated and I overlooked the fact that some of the parts I dropped off were not only made from steel...

As you can see I had these windshield wiper mechanisms plated. They came back looking good as new, except that the tiny drive gear must be made of some soft metal and has melted in the process..

Let this serve as a warning to anyone getting parts plated to make sure exactly what metal you are dropping off.

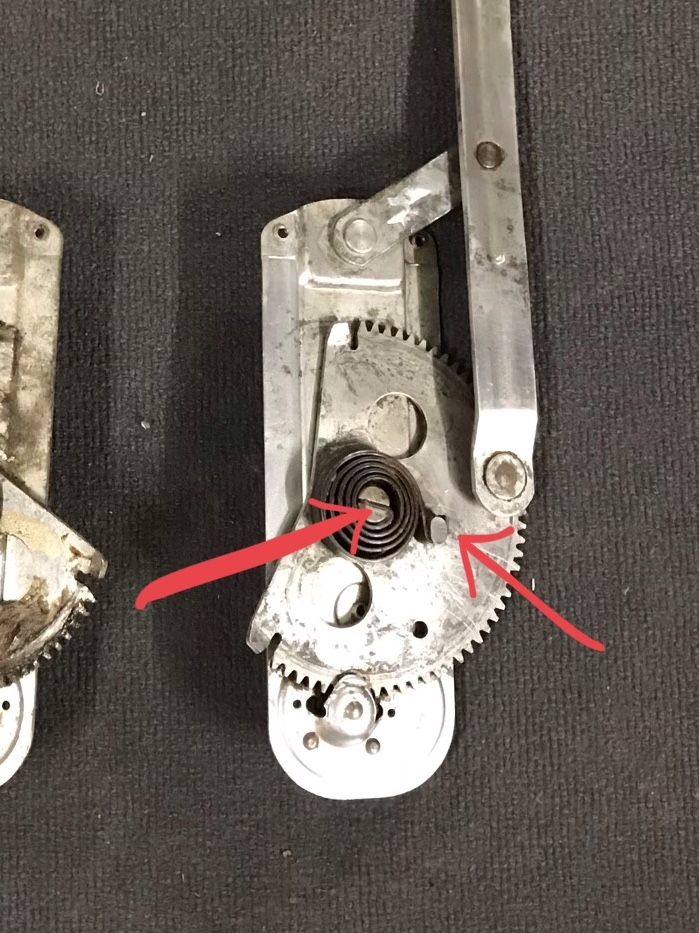

I also lost some pins from my window winder mech mechanism which i will have to fabricate. This picture was before plating, the spring was removed but the pins not.. now they are gone.

Now, I was lucky enough to find some replacement parts for a reasonable price. But as you can see they’re not so petty..

Is it possible to remove the little gear off the replacement and transfer it to my already plated parts?

If not, how should I go about restoring these parts without plating them?

As you can see I had these windshield wiper mechanisms plated. They came back looking good as new, except that the tiny drive gear must be made of some soft metal and has melted in the process..

Let this serve as a warning to anyone getting parts plated to make sure exactly what metal you are dropping off.

I also lost some pins from my window winder mech mechanism which i will have to fabricate. This picture was before plating, the spring was removed but the pins not.. now they are gone.

Now, I was lucky enough to find some replacement parts for a reasonable price. But as you can see they’re not so petty..

Is it possible to remove the little gear off the replacement and transfer it to my already plated parts?

If not, how should I go about restoring these parts without plating them?