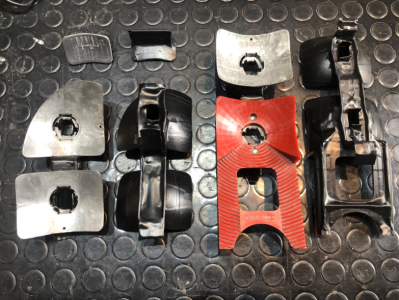

Reviewed what's salvageable on my hood torsion mechanism....

Disassembled the system from the car, in the upright position there is no tension on the system.

- Chopped 1 of the welded and broken again arm. Cleaned it to see what I had to work with; it's not missing much, but has a tear in the arm itself. I may choose to strengthen the arms as well. I left the other arm still attached to the tube, so i can copy the exact placement onto a new, thicker tube.

- Cleaned the bracket that holds the soft metal block to the hood. It was (unintentionally?) touched with an angle grinder and welded upon. removing the corroded remains left quite a hole to patch a new piece of 2,5 mm thick steel in.

- cleaned the torsion twist rods. They have not suffered anything over the past 50 years. Will have them electrolytically zinc treated before 2k painting them black (they are originally black from factory) .

Ordered a new 1062x26x22 mm steel tube. I hope to weld the arms to it, and have it re-zinced as well.

One open question to the gruppe: does anyone have experience with setting placing a new rivet like the ones used in the hinge of the arms?

The hinge point is made with a rivet, the two arm sections, and a ring between the two arms.

As Ii would like to re-zinc the system, I think the inside surfaces of the hinge , the rivet and the ring do not coated very well with Zinc due to the electric fields being very weak around these narrow openings. So one option is to drill out the hinge, and place a new rivet.

But I've never seen anyone do that at home - does it needs special equipment to press it to give it it's nice, round head shape? I guess one would also have to have the rivet custom made.