sreams

Well-Known Member

Wondering what the experts thoughts are on this.

I have a 1991 M30B35 with dual Weber DGEV carbs on the old Zenith intake manifolds. I have port matched the manifolds to the intake ports on the head (B35 ports are larger). Carbs were jetted using a wideband O2 sensor and AFR Gauge. The motor pulls brilliantly.

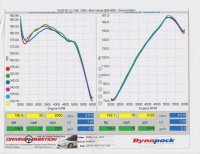

I have noticed, and a dyno test confirms, that while the motor will go all the way to the redline, power stops increasing at about 5100-5200rpm. I have a 165rwhp peak at 5148rpm, and a 185lbft rw torque peak at about 3400rpm.

According to BMW specs, a stock, injected M30B35 has a horsepower peak at 5800rpm. If I extrapolate the hp curve from my dyno run out to 5800rpm, the rwhp peak should approach 180.

Obviously, my motor is different from a stock M30B35 since I have carbs on it.

So here is the question for the experts: What do you think is limiting power after 5100rpm?

Is it the DGAVs (which suggests Weber DGES 38s might be worth the investment)?

Or is it the old Zenith manifolds (which suggests Weber 38s would do nothing other than change throttle response)?

Edit: Forgot to mention I am running M30B35 exhaust manifolds and a custom 2.5" exhaust with free-flowing mufflers and obviously no cat.

I have a 1991 M30B35 with dual Weber DGEV carbs on the old Zenith intake manifolds. I have port matched the manifolds to the intake ports on the head (B35 ports are larger). Carbs were jetted using a wideband O2 sensor and AFR Gauge. The motor pulls brilliantly.

I have noticed, and a dyno test confirms, that while the motor will go all the way to the redline, power stops increasing at about 5100-5200rpm. I have a 165rwhp peak at 5148rpm, and a 185lbft rw torque peak at about 3400rpm.

According to BMW specs, a stock, injected M30B35 has a horsepower peak at 5800rpm. If I extrapolate the hp curve from my dyno run out to 5800rpm, the rwhp peak should approach 180.

Obviously, my motor is different from a stock M30B35 since I have carbs on it.

So here is the question for the experts: What do you think is limiting power after 5100rpm?

Is it the DGAVs (which suggests Weber DGES 38s might be worth the investment)?

Or is it the old Zenith manifolds (which suggests Weber 38s would do nothing other than change throttle response)?

Edit: Forgot to mention I am running M30B35 exhaust manifolds and a custom 2.5" exhaust with free-flowing mufflers and obviously no cat.

Attachments

Last edited: