I'm embarking into new territory regarding the potential of the 123 distributor that I think is being overlooked. I am no engine expert but from my research on the web (dangerous I know), that old school tuners used to set initial timing with a vacuum gauge and/or a "highest idle" procedure. From what I have determined, engines typically like more initial or static advance than the owner's manual suggests (for emissions and/or erring on conservative), all you have to do is twist your distributor counter clockwise and see for yourself just how much. This indicates a more efficient fuel burn at idle. Free power. The racer discussions are in favor of setting the idle advance as high as the engine likes, until adding more no longer results in a higher vacuum or idle rpm, then back off a little to compensate for fuel quality etc. Especially if you have a bigger cam like I do. The issue that always comes up is that if you do that, then total advance (when you add in the mechanical advance spec'd in the distributor) you'll have too much all-in and your engine will ping at best or grenade at worst. However this argument is moot with the 123 because you can control the "mechanical" portion with a computer or iphone.

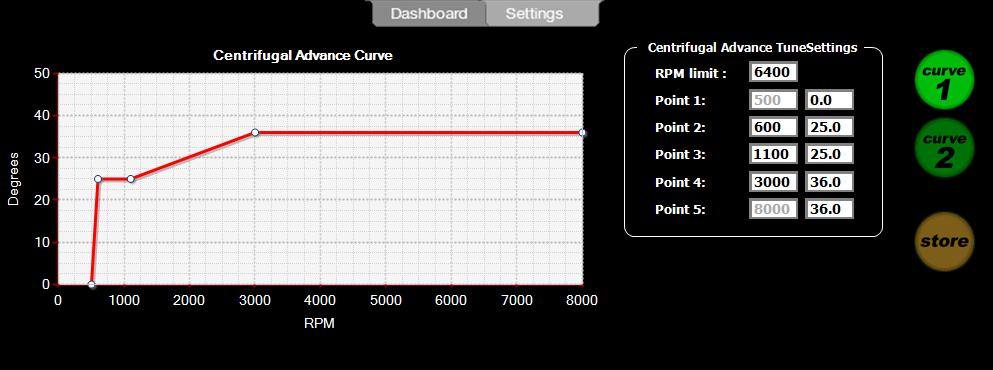

I have said before that one of the great things about the 123 with Weber sidedrafts is that you can adjust the throttle plates to the perfect position in regards to the first progression hole (a critical adjustment for off-idle performance) by compensating either up or down with the static timing to achieve proper idle rpm. This was not possible back in the day so people compensated by opening up the throttle at idle or putting in less than ideal jetting. I have proven this to myself too many times. So this has led me to the next step down the rabbit hole in that now I am experimanting with an even higher static advance because recently, just for kicks I bumped my initial timing up to where the idle responded to the max which turned out to be about 25 degrees btdc. Every engine is different based on age, compression ratio, cam etc and it will tell you when you've gone too far when the idle or vacuum drops off. I then programmed the distributor curve for 11 more degrees from idle to all in 3000 rpm so total advance is still 36 btdc which is in line with spec. No vacuum advance. The only way to do this with a traditional distributor is to have it physically rebuilt, it can be done any number of times and configurations on the 123 in 5 minutes and of course is reversible. So why not said the curious cat.

The "snap" off idle and initial acceleration took me by surprise, it's amazing. One race builder site says this is how they build their engines - a lot of initial advance and only a little mechanical. I've read that Webers "like" a lot of advance. As does a bigger cam. However my Webers at 25 btdc required the throttles to be closed quite a bit in order to keep the idle at or below 1000rpm and so was hard to get the right smooth idle mixture. So my goal is to see what the point is where I can maximize static advace and still keep the throttle plates in an optimal posiiton for idle quality/AFR and will post my findings here for any others interested (if any ).

).

In the meantime I'd appreciate any opinions or other precautions by heading in this direction. The off-the-line acceleration is most defintiely better than my stock timing specs. Here is the curve I'll be tweaking, I suspect it will end up somewhere between 25 and the 15 initial advance I am using now:

I have said before that one of the great things about the 123 with Weber sidedrafts is that you can adjust the throttle plates to the perfect position in regards to the first progression hole (a critical adjustment for off-idle performance) by compensating either up or down with the static timing to achieve proper idle rpm. This was not possible back in the day so people compensated by opening up the throttle at idle or putting in less than ideal jetting. I have proven this to myself too many times. So this has led me to the next step down the rabbit hole in that now I am experimanting with an even higher static advance because recently, just for kicks I bumped my initial timing up to where the idle responded to the max which turned out to be about 25 degrees btdc. Every engine is different based on age, compression ratio, cam etc and it will tell you when you've gone too far when the idle or vacuum drops off. I then programmed the distributor curve for 11 more degrees from idle to all in 3000 rpm so total advance is still 36 btdc which is in line with spec. No vacuum advance. The only way to do this with a traditional distributor is to have it physically rebuilt, it can be done any number of times and configurations on the 123 in 5 minutes and of course is reversible. So why not said the curious cat.

The "snap" off idle and initial acceleration took me by surprise, it's amazing. One race builder site says this is how they build their engines - a lot of initial advance and only a little mechanical. I've read that Webers "like" a lot of advance. As does a bigger cam. However my Webers at 25 btdc required the throttles to be closed quite a bit in order to keep the idle at or below 1000rpm and so was hard to get the right smooth idle mixture. So my goal is to see what the point is where I can maximize static advace and still keep the throttle plates in an optimal posiiton for idle quality/AFR and will post my findings here for any others interested (if any

In the meantime I'd appreciate any opinions or other precautions by heading in this direction. The off-the-line acceleration is most defintiely better than my stock timing specs. Here is the curve I'll be tweaking, I suspect it will end up somewhere between 25 and the 15 initial advance I am using now:

Last edited: