So, this happened:

www.youtube.com

www.youtube.com

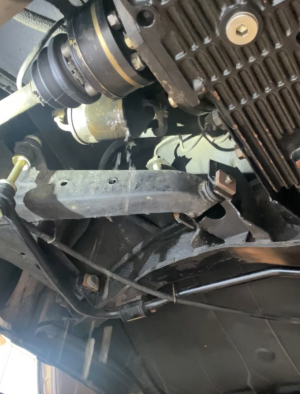

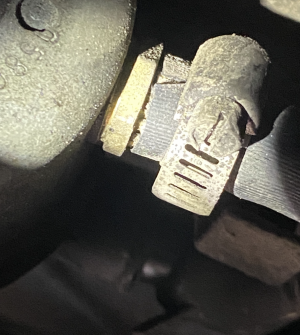

While my garage airs out, and before I stick my head up there, any armchair diagnosticians have an opinion on whether a fuel pump itself would leak this badly, or is this just a loose line?

Thanks in advance...

- YouTube

Enjoy the videos and music you love, upload original content, and share it all with friends, family, and the world on YouTube.

While my garage airs out, and before I stick my head up there, any armchair diagnosticians have an opinion on whether a fuel pump itself would leak this badly, or is this just a loose line?

Thanks in advance...