I am restoring my harness, I replaced the broken and missing wires but I want to check if the old wires are working properly.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

How to know if a wire is working properly?

- Thread starter alprada70

- Start date

In general you want to test wire harnesses for opens, shorts, and resistance when they are meant to carry DC only.

You want to measure other things when they carry signals with their own frequency spectrum (attenuation, crosstalk, etc.) and that takes you into the area of cable testers.

I think all cables in my E9 carry DC, maybe a fuel injected car carries true signals to/from the ECU through cables.

To measure resistance you use the ohmmeter across the ends of the cable and look for something very close to zero ohms. You repeat the test including now the connectors and look for a small addition of perhaps 0.1 ohms. Now you jiggle the cable and make sure the resistance is steady rather than intermittent phenomena.

Now you keep one ohmmeter end on the wire and check for resistance to every other end of the harness, and to ground if the harness is already in place. If any show finite resistance you have a short. Jiggle and repeat to find intermittent shorts.

For AC signals things get more interesting, in general you measure cables in pairs that carry a signal, where my preferred method for seeing what a channel is, is TDR, namely send a pulse from one side and observe the reflection...

You want to measure other things when they carry signals with their own frequency spectrum (attenuation, crosstalk, etc.) and that takes you into the area of cable testers.

I think all cables in my E9 carry DC, maybe a fuel injected car carries true signals to/from the ECU through cables.

To measure resistance you use the ohmmeter across the ends of the cable and look for something very close to zero ohms. You repeat the test including now the connectors and look for a small addition of perhaps 0.1 ohms. Now you jiggle the cable and make sure the resistance is steady rather than intermittent phenomena.

Now you keep one ohmmeter end on the wire and check for resistance to every other end of the harness, and to ground if the harness is already in place. If any show finite resistance you have a short. Jiggle and repeat to find intermittent shorts.

For AC signals things get more interesting, in general you measure cables in pairs that carry a signal, where my preferred method for seeing what a channel is, is TDR, namely send a pulse from one side and observe the reflection...

thank you !!

explanation for dummies? the harness are in the table...

explanation for dummies? the harness are in the table...

I hope you are making the harness respecting the original color codes. Yes you can test on the bench but ideally with a set of connectors as the contact resistance is a major concern. Hope you will offer harnesses for sale eventually.

Arde is correct, if not maybe a bit over complicated for a car harness.

In an E9, no signal is high enough frequency to require any special handling (i.e with a coaxial cable). The closest thing to a special wire might be the signal from the distributor to the coil (or from an ignition box the the distributor if you have a separate ignition box.

Everything else is DC. So, the primary test of a wire is to see that it has electrical continunity (i.e. very low resistance) from one end to the other(s). The "other(s)" being plural since one wire may split and go to multiple places.

So Test #1 is to confirm that the contact on one end of a wire has low resistance to the contact(s) on the other end of any wires it is supposed to connect to.

The second test is to confirm that the wire isn't accidentally connected to anything else. In a new harness, this would be a wiring error. In an old harness it would be a short circuit. You do this by measuring the continuity between that contact and every other contact that is not supposed to be connected to it (a time consuming, but important activity).

IMO any wires that may or may not short by "jiggling" or shifting the harness should be replaced. Easy to do, and cheap insurance against a fire, or damaging some component.

If you have a really long wire, and want to know where it is broken, then , yes, as Arde describes, you can use a time domain reflectometer (TDR) to determine where the wire is broken. this test basically sends a pulse down the wire. If the wire has a break, the pulse will bounce back (reflect), and this can be observed using the TDR. The time it takes to reflect test you how far away the break is. Remember the pulse travels at the speed of light, which is 1 nanosecond per foot, So using this technique in a car harness would require a very fast TDR, since most wires are likely to be less than about 10-15 feet long (round trip travel time 20-30 sec)...

In an E9, no signal is high enough frequency to require any special handling (i.e with a coaxial cable). The closest thing to a special wire might be the signal from the distributor to the coil (or from an ignition box the the distributor if you have a separate ignition box.

Everything else is DC. So, the primary test of a wire is to see that it has electrical continunity (i.e. very low resistance) from one end to the other(s). The "other(s)" being plural since one wire may split and go to multiple places.

So Test #1 is to confirm that the contact on one end of a wire has low resistance to the contact(s) on the other end of any wires it is supposed to connect to.

The second test is to confirm that the wire isn't accidentally connected to anything else. In a new harness, this would be a wiring error. In an old harness it would be a short circuit. You do this by measuring the continuity between that contact and every other contact that is not supposed to be connected to it (a time consuming, but important activity).

IMO any wires that may or may not short by "jiggling" or shifting the harness should be replaced. Easy to do, and cheap insurance against a fire, or damaging some component.

If you have a really long wire, and want to know where it is broken, then , yes, as Arde describes, you can use a time domain reflectometer (TDR) to determine where the wire is broken. this test basically sends a pulse down the wire. If the wire has a break, the pulse will bounce back (reflect), and this can be observed using the TDR. The time it takes to reflect test you how far away the break is. Remember the pulse travels at the speed of light, which is 1 nanosecond per foot, So using this technique in a car harness would require a very fast TDR, since most wires are likely to be less than about 10-15 feet long (round trip travel time 20-30 sec)...

I am a bit of a newbie/nitwit on electrical stuff, so I brought my harness to my PhD electrical dad who insisted to test the wires under load, so with a bright burning headlight bulb at the other end.

This way he explained, you can not only find a fully broken wire, but also identify when a wire has a significant bunch of broken strands.

You have to feel by hand if any connector and/or wire turns hot.

In my case we found a few broken wires, + a few spade connectors and earth points where the crimped wire partly separated at the crimp. ( vibrations?)

So the conductivity with a voltmeter showed perfect readings, but it got hot when loading it up.

Resistance testing a 3/4 broken wire without the headlight bulb in the loop will show it conducts just fine: the few intact strands will be adequate for the low flow.

But when pumping higher volumes of current (amps? I always mix it up) through it, it'll get hot and burn.

This way he explained, you can not only find a fully broken wire, but also identify when a wire has a significant bunch of broken strands.

You have to feel by hand if any connector and/or wire turns hot.

In my case we found a few broken wires, + a few spade connectors and earth points where the crimped wire partly separated at the crimp. ( vibrations?)

So the conductivity with a voltmeter showed perfect readings, but it got hot when loading it up.

Resistance testing a 3/4 broken wire without the headlight bulb in the loop will show it conducts just fine: the few intact strands will be adequate for the low flow.

But when pumping higher volumes of current (amps? I always mix it up) through it, it'll get hot and burn.

Last edited:

great tip!

VERY good point!!I am a bit of a newbie/nitwit on electrical stuff, so I brought my harness to my PhD electrical dad who insisted to test the wires under load, so with a bright burning headlight bulb at the other end.

This way he explained, you can not only find a fully broken wire, but also identify when a wire has a significant bunch of broken strands.

You have to feel by hand if any connector and/or wire turns hot.

In my case we found a few broken wires, + a few spade connectors and earth points where the crimped wire partly separated at the crimp.

So the conductivity with a voltmeter showed perfect readings, but it got hot when loading it up.

( vibrations?)

Resistance testing it without the headlight bulb will show it conducts just fine: the few intact strands will be adequate for the low flow.

But when pumping higher volumes of current (amps? I always mix it up) through it, it'll get hot and burn.

Power (measured in Watts) in an electrical circuit is the combination of current and resistance. Since the wires are not physically moving anything the power is dissipated as heat. The mathematical relationship is P=I^2R, where the I^2 means current (in Amperes) squared. R is the resistance in Ohms.

So, you can see if R increases, as @eriknetherlands has described (because the current is flowing through less and less wire as the strands break), then the power increases for the same current. In some cases we see this interms of reduced performance of the part being powered (slow stater, dim lamp, etc). However, since the relation is I^2 and not just I, there is generally always added power dissipation from this situation, and that means heat. Heat then causes more degradation in the wires and the process accelerates. *

The strands break from vibration, and in some cases from corrosion. Where the copper is exposed 9lie at a crimp connection) it will corrode over time, and eventually the strands break, one by one.

In marine electrical applications they usually use tin plated copper wire to minimize this. Each wire in the strand is tin plated, so the wire looks like a twisted set of silver strands. The same will happen if the insulation cracks. Insulation cracks either from long term heat, or just age. If any of you have not read @BarneyT 's account of his small electrical fire, that is a good lesson in what can happen with old cracked insulation...

I think I am going to just re-make the entire harness, either that, or splurge and buy the replacement.

* For those not familiar with basic electricity, the voltage, current and resistance in a circuit have a very well-defined relationship, which is described by a relations known as Ohm's Law. This states V=IR, where V is the voltage (Volts), I is the current (Amperes, or usually just called Amps) and R is the resistance in Ohms. You can see the effects we often observe by looking at a simple circuit using Ohm's Law. Below is a pair of resistors. One (Rl) is the "load", which is the thing that we are trying to power (lamp, starter motor, wiper motor, etc). Rw is the resistance of the wire feeding that load. The resistance might be distributed along the entire wire (true for a small wire), or more likely, it is found at certain points, such as a splice, a near-brake, or a frayed crimp connection. The location of the resistance is not super critical.

In the figure below we can see tat we have a 12 Volt battery feeding current to the load, but the load is connected via a wire with resistance R(wire). What this means is that with fixed voltage (12 Volts in a car) the current through the load will be I=V/(R(lamp)+R(wire). This is Ohms law re-arranged to give current as a function of voltage and (total) resistance. Since we also know, from Ohm's Law that the voltage drop across any given resistance is Vd=IR, we can determine the voltage at the load by simply multiplying the current I=V/(R(lamp)+R(wire)) times the load resistance R(lamp).

Here we get V(lamp)=V(R(lamp))/(R(wire)+R(lamp)).

So, if the load is, a 12 Watt lamp, the resistance of the lamp, with a perfect zero resistance wire and a 12 Volt battery would be 12=I^R=(V/R)^2R=V^2/R=144/R.

Or, R=12 Ohms.

Now put that same lamp in a circuit fed by a wire with 2 Ohms of resistance. Using the relation above (in the diagram) the voltage on the lamp is now

V(lamp)=12(12)/(2+12)=144/14=10.29 Volts, and the power output of the lamp will go down from 12 watts to V^2/R=(10.29)^2/12=8.824 Watts... So the lamp will dim.

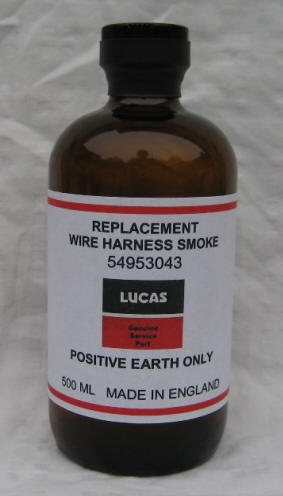

We use an extension cord with the outlet cut off and stripped to bare wire. 120v will show shorts and broken wires in 1 second.

Just watch for the smoke….

Just watch for the smoke….

YIKES!!!We use an extension cord with the outlet cut off and stripped to bare wire. 120v will show shorts and broken wires in 1 second.

Just watch for the smoke….

Probably best to not use that method when checking the gas gauge connection!!

We use an extension cord with the outlet cut off and stripped to bare wire. 120v will show shorts and broken wires in 1 second.

Just watch for the smoke….

PhD approach vs hands-on (like me...)

VERY good point!!

Power (measured in Watts) in an electrical circuit is the combination of current and resistance. Since the wires are not physically moving anything the power is dissipated as heat. The mathematical relationship is P=I^2R, where the I^2 means current (in Amperes) squared. R is the resistance in Ohms.

.......

more difficult stuff

.......

So the lamp will dim.

Yeah, If i actually paid attention in physics class i should have been able to write that.

I'm happy you listened ...

Always put the smoke back in…YIKES!!!

Probably best to not use that method when checking the gas gauge connection!!

Attachments

Well, my take is slightly different, though the method is the same.

If you had 1/2 the number of strands damaged or removed, the wire resistance would double and the ohmmeter test would show that. After all resistance is constant vs. current in general for a wire.

You would see the best wires have resistance R and the bad ones 2R. You may see dimmer lights but I do not believe this would burn the wire as the increase in wire resistance would halve the current under high load, and the moment heat develops the wire resistance increases again further limiting the current.

The more realistic and problematic scenario is that you have half the strands at a specific pressure point. The reason the ohmmeter will not catch it is that the strands touch each other for the entire length of the wire, and thus continue to have the same parallel resistance with a tiny increase of the few mms where it is crimped. The problem is not that the wire resistance changed, it did not, the problem is high current density per strand at the crimped point. The current is not limited under load, so the heat develops locally at that small crimped point.

Net-net, you have to stress test it to find that type of problem, as Erik's father suggests.

If you had 1/2 the number of strands damaged or removed, the wire resistance would double and the ohmmeter test would show that. After all resistance is constant vs. current in general for a wire.

You would see the best wires have resistance R and the bad ones 2R. You may see dimmer lights but I do not believe this would burn the wire as the increase in wire resistance would halve the current under high load, and the moment heat develops the wire resistance increases again further limiting the current.

The more realistic and problematic scenario is that you have half the strands at a specific pressure point. The reason the ohmmeter will not catch it is that the strands touch each other for the entire length of the wire, and thus continue to have the same parallel resistance with a tiny increase of the few mms where it is crimped. The problem is not that the wire resistance changed, it did not, the problem is high current density per strand at the crimped point. The current is not limited under load, so the heat develops locally at that small crimped point.

Net-net, you have to stress test it to find that type of problem, as Erik's father suggests.

This works, except most ohm meters are not super accurate down at low resistances, and many folks may use the "continuity" tester instead, which really can't differentiate these small resistances.Well, my take is slightly different, though the method is the same.

If you had 1/2 the number of strands damaged or removed, the wire resistance would double and the ohmmeter test would show that. After all resistance is constant vs. current in general for a wire.

You would see the best wires have resistance R and the bad ones 2R. You may see dimmer lights but I do not believe this would burn the wire as the increase in wire resistance would halve the current under high load, and the moment heat develops the wire resistance increases again further limiting the current.

The more realistic and problematic scenario is that you have half the strands at a specific pressure point. The reason the ohmmeter will not catch it is that the strands touch each other for the entire length of the wire, and thus continue to have the same parallel resistance with a tiny increase of the few mms where it is crimped. The problem is not that the wire resistance changed, it did not, the problem is high current density per strand at the crimped point. The current is not limited under load, so the heat develops locally at that small crimped point.

Net-net, you have to stress test it to find that type of problem, as Erik's father suggests.

Good point about a point break...The resistance is related to the length of wire, so if there is a frayed connection point, but the rest of the wire is good, then you might not catch this, even with the bulb test. So Don's arc welding approach might actually make sense!!

I think testing with a headlight load is an excellent idea, but Iʻd use my accessory thermal camera on my phone to look for warm spots in the length and at the connectors of the harness. It takes longer to see the results than Donʻs 120v example but has the advantage of being nondestructive. Not cheap, but useful for many things such as finding a water leak in your house or car or spots of missing insulation in your walls or attic. I think itʻs a tool well worth the money. Notice the far terminal clamp charging the battery looks hotter than the near one. I should look at that one to make sure the wire is firmly contacting the clamp. Battery charging uses a lot of current, so itʻs normal for the wires and battery to warm up during charging. In this exercise we are looking for abnormally hot spots.

TOPDON TC002C Thermal Camera, 256 x 192 IR Resolution

Amazon 249.00

TOPDON TC002C Thermal Camera, 256 x 192 IR Resolution

Amazon 249.00