Hello everyone,

here is my project. Nearly 2 years ago I bought a very good 72 CS bare shell that sitting in a barn for like 20+ years with a bunch of parts. I had no idea what I want to build.

My first idea was a complete restomod with M62b44 engine, zf s5d gearbox from e36m3, ITB setup, standalone ecu, MK60 abs, R&P steering, custom rear suspension with strut towers, e24/e28 rear end, LSD, rear bracing, some underside bracing, stitch welded chassis and some other goodies.

Engine and gearbox was already adapted to the Car, engine mounts fabricated, transmission tunnel enlarged and custom brake linkage for E32 Brake booster.

Then after driving a v8 swapped e30 I found this engine not so suitable for e9 chassis. So I removed it and sold it.

Also get away from custom rear strut towers (don’t want to cut out all of the perfect parts, if I had rust i would consider this more). So I went back to oem rear end but with rear coilovers and some bracing inside trunk to support towers and add stiffness also to differential area.

Now I will continue with some straight 6 engine. S54 and S38 was in the selection. At the end, I found the s38 a little more interesting, because I already had previous 2 e46 m3s with the s54 (a piece of finest engineering btw!, but had never a car with m88 or s38.

So I bought a S38 3.6 with getrag 5 speed from E34m5 last week.

Engine is already in. Straight drop in without any issues. Only small cut at the framerail for the thermostat housing. Made the M62 installation look like a real nightmare.

The transmission bracket I had fabricated for the M62+zf s5d does also fit by surprise this gearbox.

Radiator is a Mishimoto e36 m3 (famous in e30 scene for engine swaps), I cut out a part of the left box, welded 2 brackets to hold in place and it fits very nice with maximum cooling area.

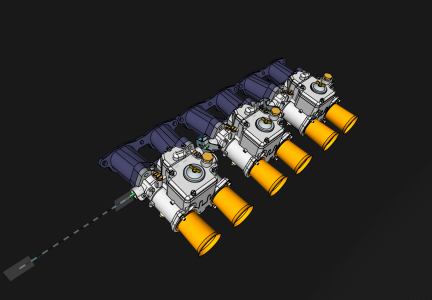

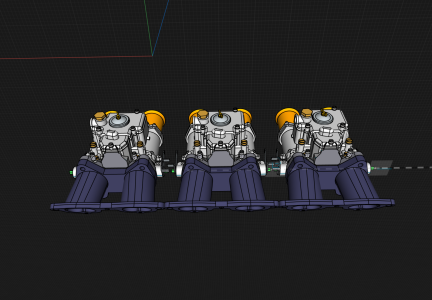

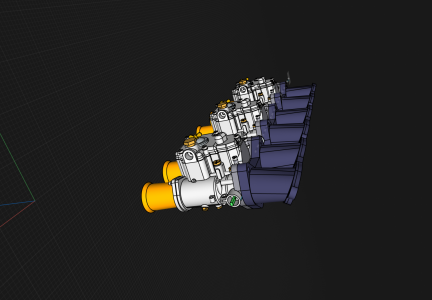

not sure about the plenum, i think i will add some nice looking (and sounding) CNC’d velocity stacks.

will do a full engine rebuild when the car is at the paintshop in a later step of the project. Some parts for this engine are a pain to buy for a reasonable price.

also made a brake setup.

I will complete everything engine related, until August when the KW custom suspension(1 year waiting time) should arrive and I can continue with rear end installation and R&P geometry,

Very very much to do and the progress is so slow. Motivation is also a problem from time to time, when you see no “results”. This is my first project that is nut to bolt.

here is my project. Nearly 2 years ago I bought a very good 72 CS bare shell that sitting in a barn for like 20+ years with a bunch of parts. I had no idea what I want to build.

My first idea was a complete restomod with M62b44 engine, zf s5d gearbox from e36m3, ITB setup, standalone ecu, MK60 abs, R&P steering, custom rear suspension with strut towers, e24/e28 rear end, LSD, rear bracing, some underside bracing, stitch welded chassis and some other goodies.

Engine and gearbox was already adapted to the Car, engine mounts fabricated, transmission tunnel enlarged and custom brake linkage for E32 Brake booster.

Then after driving a v8 swapped e30 I found this engine not so suitable for e9 chassis. So I removed it and sold it.

Also get away from custom rear strut towers (don’t want to cut out all of the perfect parts, if I had rust i would consider this more). So I went back to oem rear end but with rear coilovers and some bracing inside trunk to support towers and add stiffness also to differential area.

Now I will continue with some straight 6 engine. S54 and S38 was in the selection. At the end, I found the s38 a little more interesting, because I already had previous 2 e46 m3s with the s54 (a piece of finest engineering btw!, but had never a car with m88 or s38.

So I bought a S38 3.6 with getrag 5 speed from E34m5 last week.

Engine is already in. Straight drop in without any issues. Only small cut at the framerail for the thermostat housing. Made the M62 installation look like a real nightmare.

The transmission bracket I had fabricated for the M62+zf s5d does also fit by surprise this gearbox.

Radiator is a Mishimoto e36 m3 (famous in e30 scene for engine swaps), I cut out a part of the left box, welded 2 brackets to hold in place and it fits very nice with maximum cooling area.

not sure about the plenum, i think i will add some nice looking (and sounding) CNC’d velocity stacks.

will do a full engine rebuild when the car is at the paintshop in a later step of the project. Some parts for this engine are a pain to buy for a reasonable price.

also made a brake setup.

I will complete everything engine related, until August when the KW custom suspension(1 year waiting time) should arrive and I can continue with rear end installation and R&P geometry,

Very very much to do and the progress is so slow. Motivation is also a problem from time to time, when you see no “results”. This is my first project that is nut to bolt.