Been a while since an update, so will break it up into a few posts.

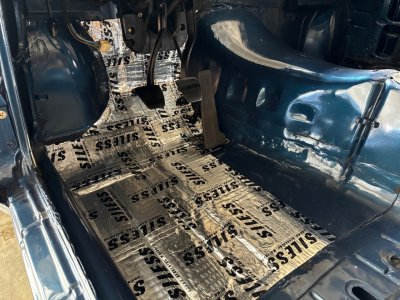

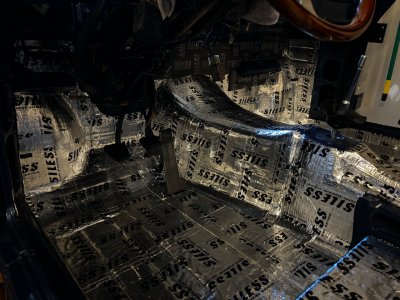

Finished up interior prep with the sound insulation complete, added the seat rail trim. Found a self-adhesive vinyl on

amazon that matches the brown carpet perfectly, and relatively easy to cut and install. One sheet did all four rails with leftover.

I then moved on to the trunk interior. First step I prepped the trunk, pulled and touched up the tank before putting back. The entire tank hand been previously restored, but I didn’t like the finish, so hit with VHT all weather black satin epoxy paint (no pic)

For the trunk, I worked with

@alprada70 to make new US spec 73 and before floor panels (fit great), and got his new side panels. I then recovered by old trunk lid panels and back of trunk panel using W&N material. The trunk organizer and white rubber trim came from CS Werks, carpet was a brand new one that came with my other CS. Finally, in installed the very old NOS wheel arch trim. These were a bit brittle, so I first treated the back side with a rubberized undercoat to give them more structure and prevent future cracking. Still have my original rear panel to rover, but mostly done

Additionally I was missing the hinge spring and hardware when I restored the exterior, so I purchased the pieces from all over the world here, and went about refinishing and painting myself. After getting bare and using a good primer, I have found this

Auto Paint Depot paint code matched spray paint to be an exceptional match. Used it for a number of brackets and the finish comes out nearly indistinguishable from the professional paint job on the exterior.

I also couldn’t help myself but to tear fit the rear seats and deck