You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

air conditioning renew

- Thread starter deQuincey

- Start date

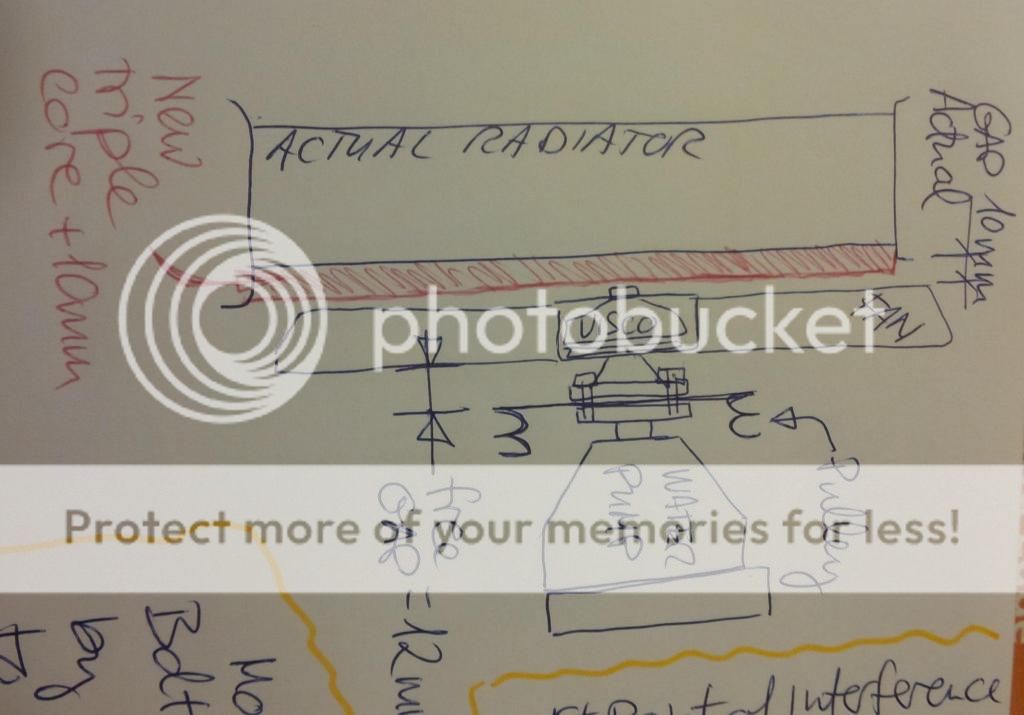

I have a triple core and the same fan/pulley setup as yours. As long as the new core doesn't extend past the edge of the top frame you should be ok. Have them try to mount the core as far forward in the frame as possible, or at least giving you as much clearance in the back as possible. I have about 15mm between the fan and the frame, more between the core and the fan.

If reusing old parts/compressors that might have run R12 before and thus might have mineral oil residues, there are two things on can do:

1. Clean out all traces of the old oil with a cleaning agent (brake cleaner might do if no proper other agent is available).

or, alternatively:

2. Drain out old oil as best as possible and then use only synthetic (PAG) A/C oil with the R134.

Reason beeing: the native oil of R12 was mineral. The native oil of R134 is esther. The R134 does not pick up and transport the mineral oil and it can get clunked up and mixed wiht the esther oil hindering propper lubrication. Since PAG works well with R134 and does not mix with the old mineral oil, it´s the best oil to use in old R12 systems that have been converted but never fully cleaned.

Interesting. Carl had mentioned good success with using Mineral Oil during a conversion to R-134a from R-12. And the conversion kit I bought came with 134a and a mineral oil charge.

Pump has a threaded nose, the clutch has the bolt which spins on so you need new pump and clutch. I have a single pulley, can't remember if it also goes to PS pump. I also have the b35 approach where harmonic balancer has double pulley though.

any number reference for that pump and its clutch and fan ?

it might be a solution

thanks

I have a triple core and the same fan/pulley setup as yours. As long as the new core doesn't extend past the edge of the top frame you should be ok. Have them try to mount the core as far forward in the frame as possible, or at least giving you as much clearance in the back as possible. I have about 15mm between the fan and the frame, more between the core and the fan.

interesting steve, i really think that something is radically different there in your car when compared to mine

can you show how the radiator ends are built ? the shop told me that they can not extend the core to the front, they say that position is defined by the lateral cavities so they can not move it frontwards

BTW, do you have the reference of the red fan ?

thanks

I will take more pics tonight. The red fan is NLA, but they come up from time to time on eBay, I got lucky on this one as it was NOS.

interesting steve, i really think that something is radically different there in your car when compared to mine

can you show how the radiator ends are built ? the shop told me that they can not extend the core to the front, they say that position is defined by the lateral cavities so they can not move it frontwards

BTW, do you have the reference of the red fan ?

thanks

Cool device, and it has a red handle!

comparing pumps and visco clutchs

please find attached two setups, on the left the e9 replacement versión

on the right the e24 newest versión

to compare i must say that in the e9 versión i did not introduce completely the visco clutch into the conical support, so you must count on 7mm more to introduce the e9 versión until final position

so when fan is placed in the e24 versión (i do not have an spare e9 fan), you see that this is what happens:

BTW: when a fan is placed on the e9 versión it flush with the top of the hexagonal screw that you can see in the e9 setup, so that is its reference point

literally, when you pull the e9 visco down 7 mm you get to the same point

this means that both the e9 and the e24 versions give you the same distance between engine and radiator !!!

so in my case there is nothing to gain

please find attached two setups, on the left the e9 replacement versión

on the right the e24 newest versión

to compare i must say that in the e9 versión i did not introduce completely the visco clutch into the conical support, so you must count on 7mm more to introduce the e9 versión until final position

so when fan is placed in the e24 versión (i do not have an spare e9 fan), you see that this is what happens:

BTW: when a fan is placed on the e9 versión it flush with the top of the hexagonal screw that you can see in the e9 setup, so that is its reference point

literally, when you pull the e9 visco down 7 mm you get to the same point

this means that both the e9 and the e24 versions give you the same distance between engine and radiator !!!

so in my case there is nothing to gain

One thing that is different - the later fan clutch that screws on is much less expensive and more obtainable than the e9 version with the hole in it, at least here in the states.

One thing that is different - the later fan clutch that screws on is much less expensive and more obtainable than the e9 version with the hole in it, at least here in the states.

ok steve, i can not tell, i know where to obtain e9 old style clutchs and reasonable prices, but there is another drawback, the e24 version is not compatible with my double pulley setup, as the pump can not hold the pulley

BTW steve i can NOT understand what is the reason why your setup leaves such a good gap, you still have to show me how the radiator ends look,...so how they are attached to the lateral supports and the relation between the core and the laterals

You can put a double pulley on harmonic balancer to drive the PS pump instead of from the water pump.

You can put a double pulley on harmonic balancer to drive the PS pump instead of from the water pump.

considering that i am not gaining gap width, not interested, i can build a frankenstein and i will not know were i am,...

I am not sure either, I didn't consciously do anything to make it work, although I think I did cut the rubber radiator mounts a little to move it forward some. Maybe I just got lucky. I will investigate tomorrow.

BTW steve i can NOT understand what is the reason why your setup leaves such a good gap, you still have to show me how the radiator ends look,...so how they are attached to the lateral supports and the relation between the core and the laterals

I am not sure either, I didn't consciously do anything to make it work, although I think I did cut the rubber radiator mounts a little to move it forward some. Maybe I just got lucky. I will investigate tomorrow.

i will appreciate that, i have been checking all, from the engine rubber mounts, to the radiator rubber mounts and brackets, i have discover no defect or error in the assembly of the various parts, i can see that i will have a similar radiator thickness once it is back from the shop,

i talked to them and they told me that it is impossible to weld it forward

so i will wait to your information to see differences

thanks

I can't find anything out of the ordinary, would it be helpful to measure the distance of the water pump housing or someother engine point to the front of the nose clip to see if our engines are the same distance from it?

so i will wait to your information to see differences

thanks

I can't find anything out of the ordinary, would it be helpful to measure the distance of the water pump housing or someother engine point to the front of the nose clip to see if our engines are the same distance from it?

it makes sense but it will take me some days,...thanks

btw, that last one was your 4000 post, congrats !

Wow, I need to get a life !

it makes sense but it will take me some days,...thanks

btw, that last one was your 4000 post, congrats !

I am hoping you pass me soon but I have an excuse, I'm retired!