James

Well-Known Member

I just finished my lamination project on my gauge cluster, and was surprised at how easy (albeit time consuming) the process was to get a nice finished product. I'm sure Bela's sets would be far nicer than what I did, but I do enjoy learning a new process and doing it myself. That being said, I still have the rest of the wood to complete...

I removed my gauge cluster from the car with ample kicking and screaming. If I hadn't had the seats out, I probably couldn't have done it, being a large person. Here is what I started with. Cracked veneer, water damaged and rusty bezels.

I removed the bezels, which popped out fairly easily, sanded them down by hand, and applied a coat of "Truck Bedliner" coating. This gave them a nice textured finish, and a little bit of sanding after two coats, and I think they look great.

I used coarse grit sand paper and a palm sander and removed the veneer down to the next layer. Its most likely important to go that far, so that the bezels will fit properly when the new veneer is laid over.

Here in San Francisco, I visited MacBeath hardwoods, where they have a great selection of veneer available (among other things). I found a helpful guy there who was interested in the project, and gave me pricing on this piece (18"x48") of zebrawood veneer based on square footage, so I received the same pricing as if I bought a full 4 foot by 8 foot sheet. I highly recommend this shop. They had many available options and many different price points, including some rather exotic and burl woods. Fun to wander around in there.

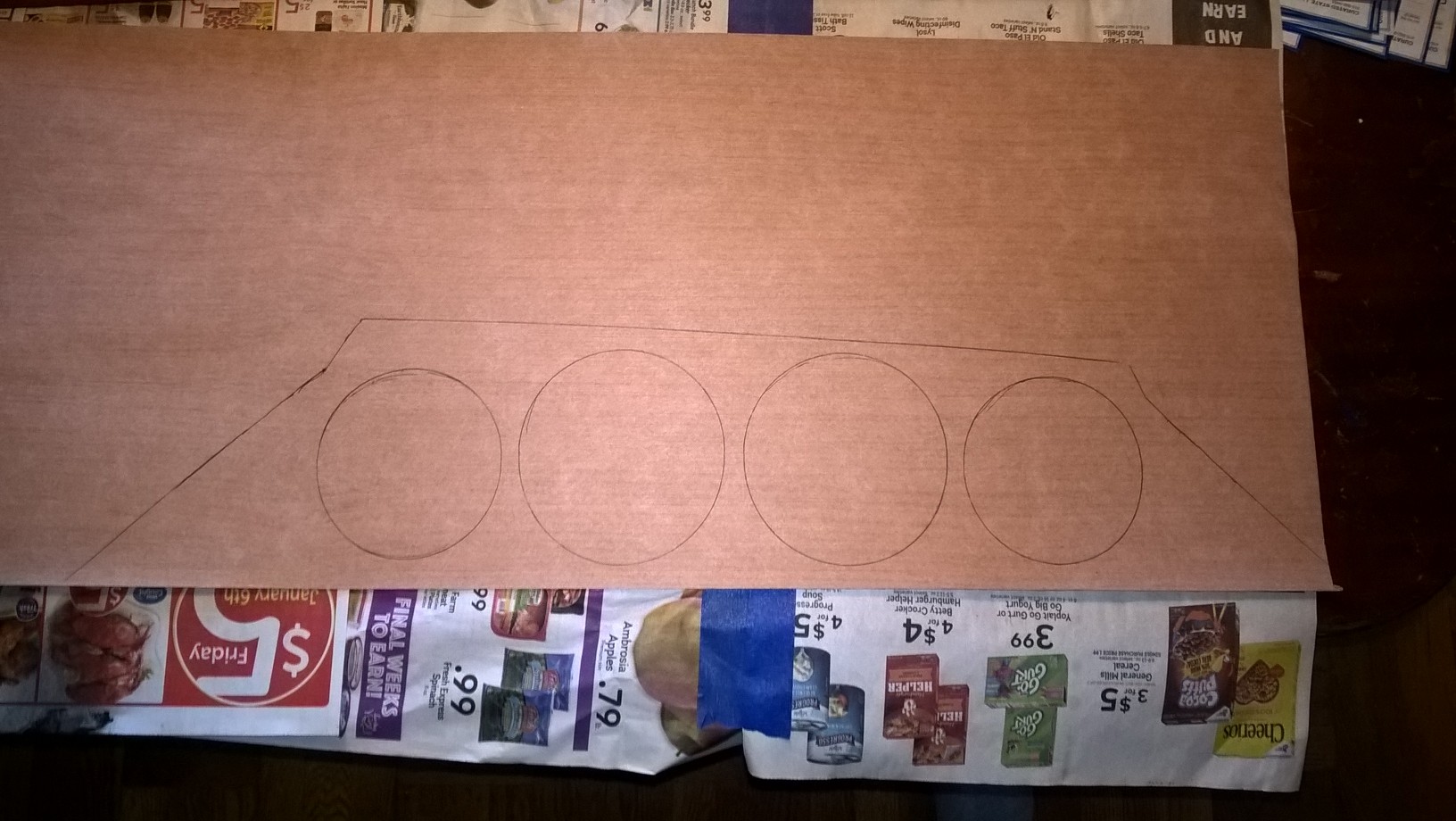

I traced the design onto the back of the sheet, leaving excess at the edges where it curves to facilitate with the steaming and bending process later. I then very carefully cut the veneer out with a razor blade. This was perhaps the most labor intensive/time consuming job. It was done sans whisky, so nearly took me two hours to make the cuts practically perfect and without splitting the wood.

I removed my gauge cluster from the car with ample kicking and screaming. If I hadn't had the seats out, I probably couldn't have done it, being a large person. Here is what I started with. Cracked veneer, water damaged and rusty bezels.

I removed the bezels, which popped out fairly easily, sanded them down by hand, and applied a coat of "Truck Bedliner" coating. This gave them a nice textured finish, and a little bit of sanding after two coats, and I think they look great.

I used coarse grit sand paper and a palm sander and removed the veneer down to the next layer. Its most likely important to go that far, so that the bezels will fit properly when the new veneer is laid over.

Here in San Francisco, I visited MacBeath hardwoods, where they have a great selection of veneer available (among other things). I found a helpful guy there who was interested in the project, and gave me pricing on this piece (18"x48") of zebrawood veneer based on square footage, so I received the same pricing as if I bought a full 4 foot by 8 foot sheet. I highly recommend this shop. They had many available options and many different price points, including some rather exotic and burl woods. Fun to wander around in there.

I traced the design onto the back of the sheet, leaving excess at the edges where it curves to facilitate with the steaming and bending process later. I then very carefully cut the veneer out with a razor blade. This was perhaps the most labor intensive/time consuming job. It was done sans whisky, so nearly took me two hours to make the cuts practically perfect and without splitting the wood.