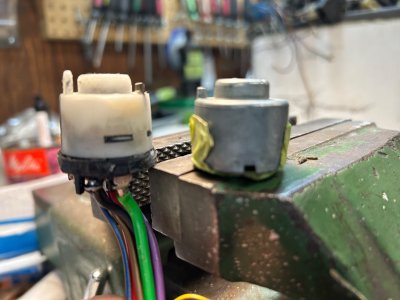

Update. I had to do this installation over. I could not stop thinking about the stress placed upon that plastic ear that holds the grub screw for the ignition switch, if the locator peg is missing. As above, the new switch has this peg at 90 degrees to the grub screw "ear" that secures the switch to the barrel in the steering column. So it must be ground off. I kept visualizing the torquing action that turning the key places on the switch. Without the peg linking the switch to the barrel, well, it is all on that little plastic ear.

So...I measured the peg on the old switch, just over 3mm or about 1/8 inch, and found this to match the mounting end of a 1/8 inch drill bit. I cut a small length off of the bottom of this bit, made a template on where exactly the peg should be, carefully drilled a small hole into the plastic case, placed my new peg inside, checked it with the old switch casing, thought it looked pretty good.

Test fit new switch again to make sure there was no interference, fit peg into drilled hole, and installed. It fit perfectly! Grub screw installed, and now I have a new switch with some measure of strength from the torque that is applied as key is turned. Just like original switch!

So...I measured the peg on the old switch, just over 3mm or about 1/8 inch, and found this to match the mounting end of a 1/8 inch drill bit. I cut a small length off of the bottom of this bit, made a template on where exactly the peg should be, carefully drilled a small hole into the plastic case, placed my new peg inside, checked it with the old switch casing, thought it looked pretty good.

Test fit new switch again to make sure there was no interference, fit peg into drilled hole, and installed. It fit perfectly! Grub screw installed, and now I have a new switch with some measure of strength from the torque that is applied as key is turned. Just like original switch!