Well, after 3 hours of puzzling, some short answers:

( More pics and tips on the removal/ install later, off to bed now)

- Yes, the bearings are correct.

- Yes, you need to have the column out of the car.

- No, you do not have to remove the steel bracket with the 4 snap bolts; I left it in place.

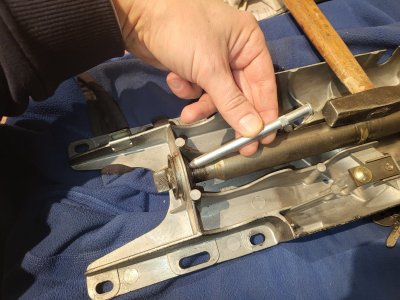

- It ain't and easy job - I really struggled with the snap rings (round wire C-clips) pn 32312083712.

Final result is however a much smoother running shaft, without any detectable play ( ofcourse I have no big 400mm Petri mounted acting as a large lever)

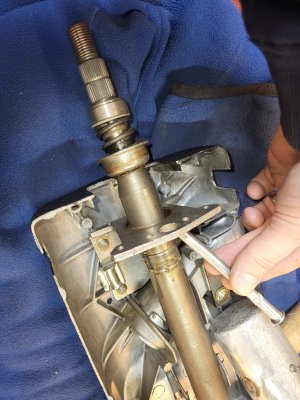

At first the bearings may seem incorrect, as the ID of the bearing is 0.25 mm larger then the shaft OD. The shaft is however pinced and centered inside the bearing with a spring ring (pn 32311116374) that is pushed inside the bearing with the large cilindrical wound spring.

Seeing the bearings being loose on the shaft at first was my first frowning moment, but it's really OK.

I had a quite of a battle with the 2 snap rings (round wire C-clips) pn 32312083712. Often axles are locked in place with these spring things with two ears with holes on them, needing these special pliers. The steering column uses such rings but without such ears. Thus they are hard to remove, but also hard to install. 3 screwdrivers were the answer, and a vice to hold the axle during the prying attempts. And you don't want to overstretch them taking them off as I at least wanted to reuse them. Also when installing the spring ring on the steering wheel side, you have to slide a aluminium sleeve over it, that prevents the spring ring from expanding.if you overstretch the ring during removal or installation, the alu ring won't fit over the ring. Also not with a big hammer. Amhik.

@deQuincey: You might want to buy 2 new ones (50 cents each) as well, so at least you can rip the old ones off with brute force.

Anyone that can chime in how professionals get them in/out?

Are the pesky rings called "flat wire circlips" ?