i agree with Peter. post a no-haggle price right here ... there is a good chance you will get it, or hopefully close.

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Best way to sell e9 these days?

- Thread starter taylorcom

- Start date

taylorcom

Well-Known Member

Could be a good idea.i agree with Peter. post a no-haggle price right here ... there is a good chance you will get it, or hopefully close.

Dude! Where have you been?So, the question I have is how much do you want for the car??

taylorcom

Well-Known Member

I've been asking just under $30k.So, the question I have is how much do you want for the car??

taylorcom

Well-Known Member

There's a new development as of yesterday: discovery of a leak in the clutch master cylinder. A failed cylinder may be the cause of clutch failure, according to sfdon. I'll need to explore that possibility.

I've found a rebuild kit: https://www.fcpeuro.com/products/bmw-clutch-master-cylinder-repair-kit-21521102625

I'm wondering if it's possible to rebuild the cylinder w/o removing it from the car (?)

I've found a rebuild kit: https://www.fcpeuro.com/products/bmw-clutch-master-cylinder-repair-kit-21521102625

I'm wondering if it's possible to rebuild the cylinder w/o removing it from the car (?)

No it must be removed and the expansion tank gets in the way as well

tdgray

Well-Known Member

But it’s not a terrible removal. The bottom bolts is a bitch but it can be done. Think it took me about a half day because I was figuring it out as I went.

Yes, the tank needs to be temporarily relocated.

Yes, the tank needs to be temporarily relocated.

The biggest challenge is holding the nuts or bolts from moving as you work in either the engine or passenger compartments. otherwise it is fairly straight forward.

taylorcom

Well-Known Member

Might be a good time to replace the expansion tank. It's a plastic one that has developed a crack just below the top opening. I do have the original brass expansion tank, which of course has a leaky seam.No it must be removed and the expansion tank gets in the way as well

A seam should be a relatively easy fix at a radiator shop. The brass tank would look great polished up, but either way it will be an improvement.

taylorcom

Well-Known Member

A fresh coat of paint would brighten it up considerably.A seam should be a relatively easy fix at a radiator shop. The brass tank would look great polished up, but either way it will be an improvement.

Attachments

taylorcom

Well-Known Member

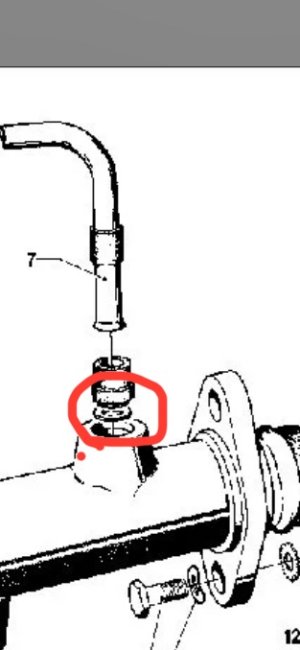

Does anyone know what this brown oval piece is (see arrow)? It's missing from a clutch master cylinder rebuild kit that arrived promptly this week.

It has been years since I rebuilt my clutch master cylinder and I cant find the pictures that I took so no help on that specific part.

Generally the parts you are most concerned with are the three rubber seals in the center of your picture. The part that is leaking is the middle seal that rides on the piston inside the cylinder and is most critical for creating pressure to move the slave cylinder.

The hard part such as the clip could always be rebuilt unless broken during removal or badly rusted.

Generally the parts you are most concerned with are the three rubber seals in the center of your picture. The part that is leaking is the middle seal that rides on the piston inside the cylinder and is most critical for creating pressure to move the slave cylinder.

The hard part such as the clip could always be rebuilt unless broken during removal or badly rusted.

AgreeI've rebuilt two of these. I'm pretty sure it goes under the grommet on top of the unit that accepts the inlet pipe.

taylorcom

Well-Known Member

It looks like I need to remove that panel in the middle of the picture in order to get to the end of the piston rod assembly to disconnect it at the pedal. I don't see an obvious way to remove, or set aside, the panel. Can anyone provide insight on this procedure? Tx

Attachments

There are a few screws that are holding the part in place.

I grabbed this picture off the internet and you can see the mounting points at the edges of the part.

- One attaches to the console side panel

- One is inside the driver's side glove (oddments) box. As I recall it is a bolt that also affixes the limiter slide for the glove box

- One is forward, towards the firewall. this one as I recall is a 10mm sheet metal screw that attaches to the same mounting point as the hinge for the driver's side glove compartment.

I grabbed this picture off the internet and you can see the mounting points at the edges of the part.

taylorcom

Well-Known Member

Thanks. It feels like I have at least 2 of the points disconnected. One seems to be hanging up. I'll check that hinge area again.There are a few screws that are holding the part in place.

- One attaches to the console side panel

- One is inside the driver's side glove (oddments) box. As I recall it is a bolt that also affixes the limiter slide for the glove box

- One is forward, towards the firewall. this one as I recall is a 10mm sheet metal screw that attaches to the same mounting point as the hinge for the driver's side glove compartment.

I grabbed this picture off the internet and you can see the mounting points at the edges of the part.View attachment 206372

taylorcom

Well-Known Member

I've removed the circlip (which broke due to my lack of circlip pliers) but can't see how to get the piston out of the cylinder. Maybe a blast of air through the feed tube?

All ideas are welcome, tx.

All ideas are welcome, tx.

This manual will help...page #61. https://e9coupe.com/tech/autobooks/autobooks_manual.pdf

You are correct, a little compressed air will move the piston and seal out of the bore. Make sure to use low pressure, and point the piston towards a container with some rags so you don't damage the piston you don't want it to score the cylinder when you re-assemble.

You will want to hone the cylinder lightly to get a fresh surface, then wash it out with brakekleen or similar. Use some brake fluid as an assembly lube and reverse your process.

You are correct, a little compressed air will move the piston and seal out of the bore. Make sure to use low pressure, and point the piston towards a container with some rags so you don't damage the piston you don't want it to score the cylinder when you re-assemble.

You will want to hone the cylinder lightly to get a fresh surface, then wash it out with brakekleen or similar. Use some brake fluid as an assembly lube and reverse your process.