Hi guys

I am looking for advice please.

I only just got my engine up and running and I don’t know if a previous owner has made adjustments to her or not, but I do know she is running way too fast on zero throttle.

My engine is ticking over at approximately 1900 to 2000 rpm so I believe it is getting excessive air from somewhere.

I have checked all intake manifold gaskets and the all seem good.

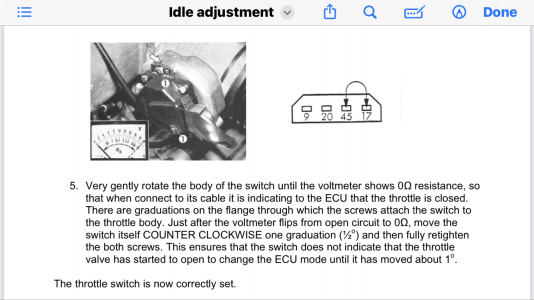

I have noticed that the butterfly on the throttle body does not actually close completely .

If I shine a light behind the butterfly I can clearly see light all around between it and the throttle body housing.

Is that normal or should it be closed fully ?

If it should be closed I think I might need to loosen the shaft clamp bolt as backing off the throttle stop screw does not seem to allow the butterfly to close. ( please advise)

Then can I also ask should I adjust the air adjustment screw to get her to tickover normally ?

I have already rebuilt the auxiliary air valve with a new wax bulb so I believe it should be working properly, although I might temporarily bypass that system just to rule it out.

Then one last question, I set all of the timing to TDC when putting her all back together, so I think that means that my ignition timing might need adjusting/ setting

Is there a “how to “ for that somewhere ?

I am looking for advice please.

I only just got my engine up and running and I don’t know if a previous owner has made adjustments to her or not, but I do know she is running way too fast on zero throttle.

My engine is ticking over at approximately 1900 to 2000 rpm so I believe it is getting excessive air from somewhere.

I have checked all intake manifold gaskets and the all seem good.

I have noticed that the butterfly on the throttle body does not actually close completely .

If I shine a light behind the butterfly I can clearly see light all around between it and the throttle body housing.

Is that normal or should it be closed fully ?

If it should be closed I think I might need to loosen the shaft clamp bolt as backing off the throttle stop screw does not seem to allow the butterfly to close. ( please advise)

Then can I also ask should I adjust the air adjustment screw to get her to tickover normally ?

I have already rebuilt the auxiliary air valve with a new wax bulb so I believe it should be working properly, although I might temporarily bypass that system just to rule it out.

Then one last question, I set all of the timing to TDC when putting her all back together, so I think that means that my ignition timing might need adjusting/ setting

Is there a “how to “ for that somewhere ?