Hi Folks,

I’m restoring a CSI wheel for a forum member. I figured I would document how to break these down.

This wheel had a cover on it. Removing it showed the leather that needs to be redone. The wheel is en route to eastern europe for a high quality recover. (edited so folks know I'm not recovering myself - I wish I was that good!) When it gets back I will hit it with a light coat of satin black paint and reassemble. While it is gone I will be making a mold of the horn pad as well as the plastic body. Both of those are in poor shape on my second CSI wheel.

Remove the horn pad, it pops off by sticking a small rod through the access hole seen at 7PM. Also note the three screws holding down the spring loaded horn plate.

But first, unscrew the horn terminal.

A view of the backside of the horn plate with springs. These are special screws.

Next, remove the plastic body from the wheel hub.

Removed:

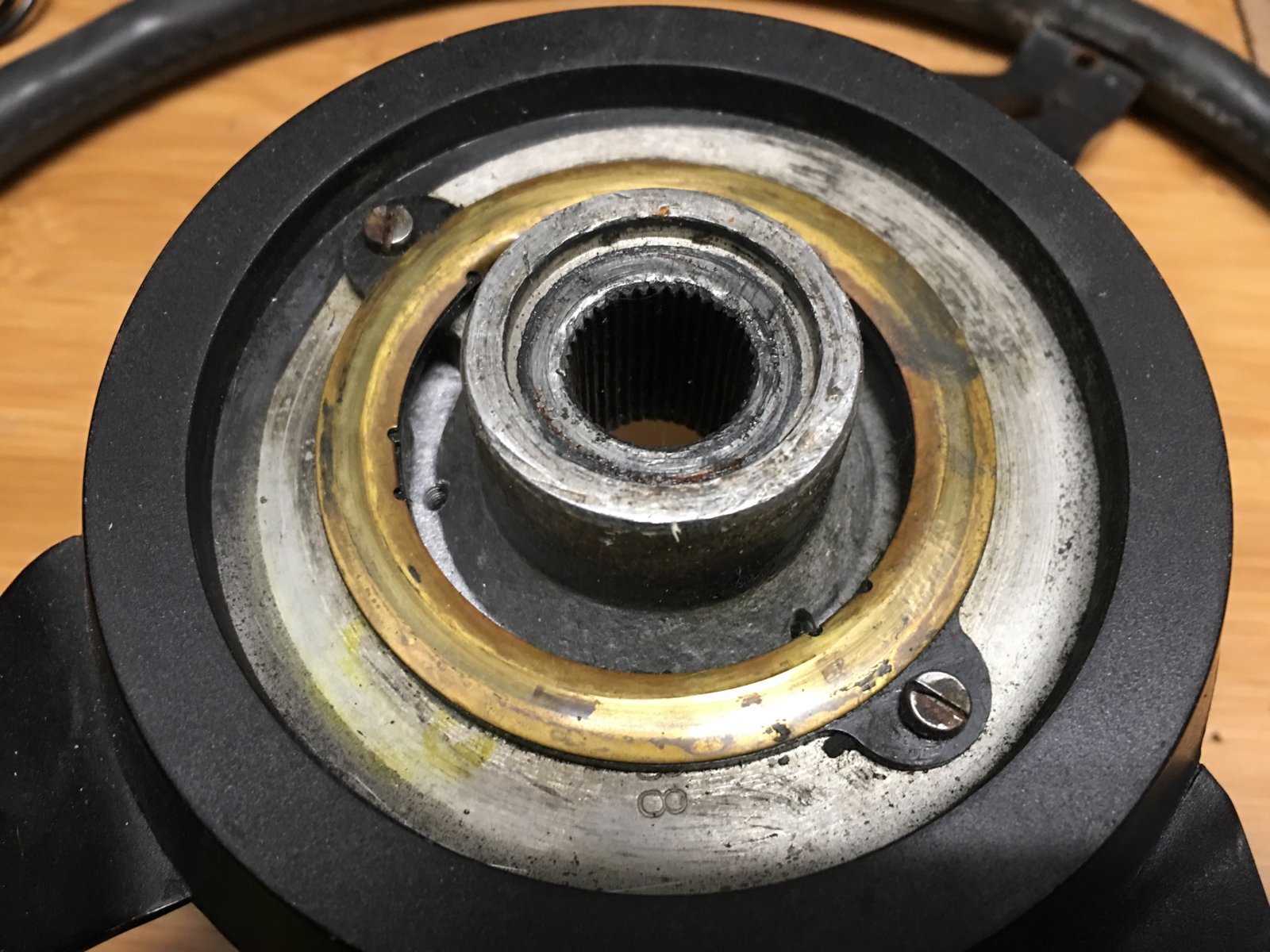

Time to remove the horn ring:

Removed.

Lastly, the chrome spoke ends. These are real metal and on the way to the chrome shop with some other small bits:

More to come next month!

I’m restoring a CSI wheel for a forum member. I figured I would document how to break these down.

This wheel had a cover on it. Removing it showed the leather that needs to be redone. The wheel is en route to eastern europe for a high quality recover. (edited so folks know I'm not recovering myself - I wish I was that good!) When it gets back I will hit it with a light coat of satin black paint and reassemble. While it is gone I will be making a mold of the horn pad as well as the plastic body. Both of those are in poor shape on my second CSI wheel.

Remove the horn pad, it pops off by sticking a small rod through the access hole seen at 7PM. Also note the three screws holding down the spring loaded horn plate.

But first, unscrew the horn terminal.

A view of the backside of the horn plate with springs. These are special screws.

Next, remove the plastic body from the wheel hub.

Removed:

Time to remove the horn ring:

Removed.

Lastly, the chrome spoke ends. These are real metal and on the way to the chrome shop with some other small bits:

More to come next month!

Last edited: