Hi all,

Yesterday I was happily cruising down the highway in heavy traffic and was greeted by a whiney sound, which at first I thought was due to the grooving in the road at that stretch. The sound quickly seemed more ominous, and as I began to merge over to exit it became downright ugly -- occasional, but not constant, grinding, clanks, etc. I got to the exit and to a gas station within one block and parked the car.

Looking under the car it became clear that the differential was leaking, very heavily. I assumed a pinion seal or the like had gone very bad. Moving (pushing) the car it was clear it was A LOT (basically all) of the fluid that was/had leaked. I was 50 miles from home; called a tow truck (its own adventure). The odd thing at that point was that the car could be pushed in neutral backward but not forward. I had them load it on a flatbed without moving the rear wheels. It's now in the street a block from my house (I'm on a hill; impossible to get it into driveway). I have to get it out of there within 3 days.

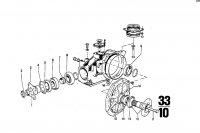

I got under the car today and found the driveshaft separated from the differential where they connect: the bolts to the diff are all in solid and in place -- it is separated such that you can see the seal clearly. The rest of the driveshaft seems fine; the Giubo is good, the junction seems fine, the u-joints are solid and bolted, etc. The only issue seems to be the gaping hole at the diff/driveshaft. In the pics I've attached you can see it as I found it and also as separated more, which is easily done by sliding the shaft assembly by hand.

To my question: what the hell? Ok, my real question is whether the part that has become disconnected is ever supposed to? Are the two pieces integral or somehow bolted together somewhere I can't see? In other cars I've had this piece (gold color in the pics) bolts onto the diff itself via multiple through bolts but here it seems to be one unit? What holds the entire driveshaft assembly tight? Pardon my ignorance here but something is obviously wrong.

Of course I don't know what damage was done internally to the differential just yet, or if I'll be able to re-fit the shaft into the diff (maybe by jacking both rear wheels off the ground, rotating them, and hopefully finding the spot where it all fits back together; though this doesn't solve the underlying problem).

Thanks in advance for any ideas, knowledge, advice, etc. to get me back on the road, much appreciated.

Yesterday I was happily cruising down the highway in heavy traffic and was greeted by a whiney sound, which at first I thought was due to the grooving in the road at that stretch. The sound quickly seemed more ominous, and as I began to merge over to exit it became downright ugly -- occasional, but not constant, grinding, clanks, etc. I got to the exit and to a gas station within one block and parked the car.

Looking under the car it became clear that the differential was leaking, very heavily. I assumed a pinion seal or the like had gone very bad. Moving (pushing) the car it was clear it was A LOT (basically all) of the fluid that was/had leaked. I was 50 miles from home; called a tow truck (its own adventure). The odd thing at that point was that the car could be pushed in neutral backward but not forward. I had them load it on a flatbed without moving the rear wheels. It's now in the street a block from my house (I'm on a hill; impossible to get it into driveway). I have to get it out of there within 3 days.

I got under the car today and found the driveshaft separated from the differential where they connect: the bolts to the diff are all in solid and in place -- it is separated such that you can see the seal clearly. The rest of the driveshaft seems fine; the Giubo is good, the junction seems fine, the u-joints are solid and bolted, etc. The only issue seems to be the gaping hole at the diff/driveshaft. In the pics I've attached you can see it as I found it and also as separated more, which is easily done by sliding the shaft assembly by hand.

To my question: what the hell? Ok, my real question is whether the part that has become disconnected is ever supposed to? Are the two pieces integral or somehow bolted together somewhere I can't see? In other cars I've had this piece (gold color in the pics) bolts onto the diff itself via multiple through bolts but here it seems to be one unit? What holds the entire driveshaft assembly tight? Pardon my ignorance here but something is obviously wrong.

Of course I don't know what damage was done internally to the differential just yet, or if I'll be able to re-fit the shaft into the diff (maybe by jacking both rear wheels off the ground, rotating them, and hopefully finding the spot where it all fits back together; though this doesn't solve the underlying problem).

Thanks in advance for any ideas, knowledge, advice, etc. to get me back on the road, much appreciated.

Last edited: