I don't know if this is already documented somewhere on this forum, couldn't find anything so I thought I could share some pictures of the process. I was a bit afraid when I started but it turned out to be quite easy and not extremely time consuming, approx an hour/gauge if you already have them out of the car and cluster.

It started with my fuel/temp-gauge looking really bad. There was a lot of spots on the inside of the glass:

I then found out that Benz-guys who have similar gauges simply took a screwdriver to the back of the chrome-bezel and started turning the screwdriver clockwise or counter-clockwise to slowly open up the chrome bezel and allow it to go over the edge of the gauge.

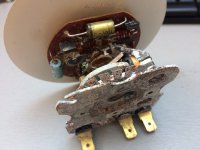

This is what the back of the chrome bezel look like:

So I started turning a small screwdriver everywhere around the gauge, slowly applying more and more pressure against the bezel.

In a while it will look something like this all the way around:

Then I took a slightly bigger screwdriver and continued, the bezel really wants to spring back, so use the force needed, but carefully. Now you can start to see the edge of the gauge:

Continue until it's possible to remove the chrome bezel "straight" out from the gauge, do not try to remove it if it still catches on to the edge of the gauge somewhere, because that will destroy/warp/twist the bezel.

After that you will have the glass, chrome bezel and the black ring separated from your gauge:

Then I took a nipper and carefully straightened out the edge of the chrome bezel:

Then I separated the glass, bezel and the black ring from each other:

And then I cleaned everything really good and started putting it back together. I used the same screwdriver to slowly press the edge of the bezel back over the edge of the gauge, takes a while but needs to be done properly to not allow new dust/crap into the gauge.

And the result:

The only downside about cleaning this gauge was that my speedometer and rpm gauge (that looked good before in comparison to this one) looked all dull and dusty now compared side to side.

So I went ahead and had them cleaned too I have not done anything to the clock yet, as it does not work (surprise), but will clean it as soon as I get it working.

I have not done anything to the clock yet, as it does not work (surprise), but will clean it as soon as I get it working.

The result of all the cleaning, they look so much better than I ever could have imagined before:

Cheers,

It started with my fuel/temp-gauge looking really bad. There was a lot of spots on the inside of the glass:

I then found out that Benz-guys who have similar gauges simply took a screwdriver to the back of the chrome-bezel and started turning the screwdriver clockwise or counter-clockwise to slowly open up the chrome bezel and allow it to go over the edge of the gauge.

This is what the back of the chrome bezel look like:

So I started turning a small screwdriver everywhere around the gauge, slowly applying more and more pressure against the bezel.

In a while it will look something like this all the way around:

Then I took a slightly bigger screwdriver and continued, the bezel really wants to spring back, so use the force needed, but carefully. Now you can start to see the edge of the gauge:

Continue until it's possible to remove the chrome bezel "straight" out from the gauge, do not try to remove it if it still catches on to the edge of the gauge somewhere, because that will destroy/warp/twist the bezel.

After that you will have the glass, chrome bezel and the black ring separated from your gauge:

Then I took a nipper and carefully straightened out the edge of the chrome bezel:

Then I separated the glass, bezel and the black ring from each other:

And then I cleaned everything really good and started putting it back together. I used the same screwdriver to slowly press the edge of the bezel back over the edge of the gauge, takes a while but needs to be done properly to not allow new dust/crap into the gauge.

And the result:

The only downside about cleaning this gauge was that my speedometer and rpm gauge (that looked good before in comparison to this one) looked all dull and dusty now compared side to side.

So I went ahead and had them cleaned too

The result of all the cleaning, they look so much better than I ever could have imagined before:

Cheers,

Last edited: