It was realised in the early 1990’s that there were some fast and expensive sports cars being built with fairly crude engine mountings and that little was available for the specialist car manufacturer when it came to design and supply of performance engine mounting systems. Vibra-technics Automotive was originally established to fill that gap. Subsequently racing and fast road saloon car mounts were developed for a variety of makes and this has grown the business to where it is now, offering over 50 specific well engineered engines and gearbox mounting systems.

The Vibra-technics Team

Vibra-technics Automotive technical staff have over 30 years collective experience in the design and manufacture of rubber components used in the automotive industry. The experience was gained working for a number of multinational rubber companies involved in the design and manufacture of chassis components used by all the major automobile manufacturers.

Why use Rubber?

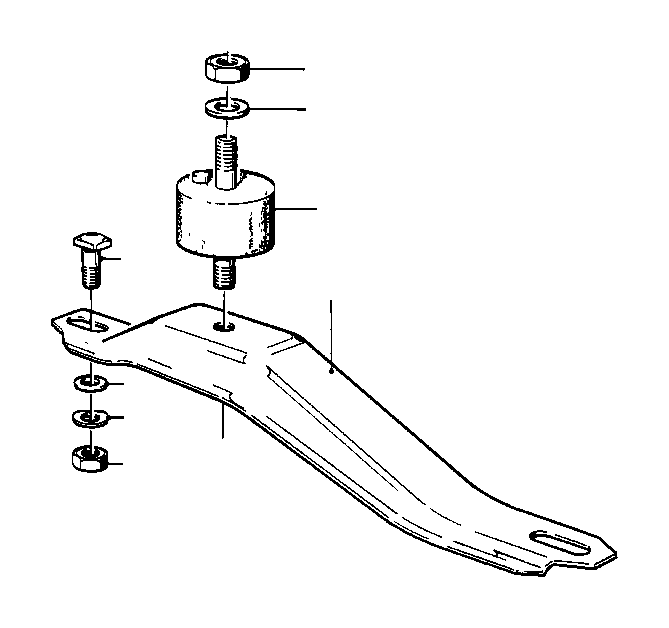

Vibra-technics products are manufactured primarily from natural rubber compounds and occasionally from blends of synthetic and natural rubber to give particular properties for specific applications. Extensive experience and testing in all kinds of environmental conditions by automobile manufacturers has shown that only natural rubber compounds give optimum performance and durability (which is why it is still used by every major car manufacturer). Where the rubber needs to be attached to metal components, this is achieved by chemically bonding the rubber to the metal during the moulding process, using the latest chemical adhesive systems.

Why fit Vibra-technics?

Vibra-technics rubber-to-metal bonded products are designed specifically for high performance applications where a direct replacement for the standard mount is required along with a much higher level of engine control to cope with higher horse power and increased levels of torque. The fast road mounts give significant improvements in ride and handling without adversely effecting vibration levels. The competition mounts also eliminate clearance problems with strut braces and exhaust systems by reducing engine movement. By reducing engine movement the car will feel far more responsive.

Benefits of Vibra-technics

- High quality well engineered engine and gearbox mounts

- Significant increase in road holding and reduced engine movement

- Increase in throttle response

- Will not deteriorate like the factory fit bushes

- By changing the front engine mount only you will notice a big difference in reduced engine movement and throttle response

- Available for a wide range of performance vehicles

- A brand well known all over the world for quality and for producing results