Hi Folks,

I'm making myself a 6061 water jet cut aluminum spacer for my t-stat housing. I arrived at a 32mm spacer that allows my housing to clear the adjuster on my type 152 DCOE 40's. The end product may be within a mm or so of this, as I have some flexibility.

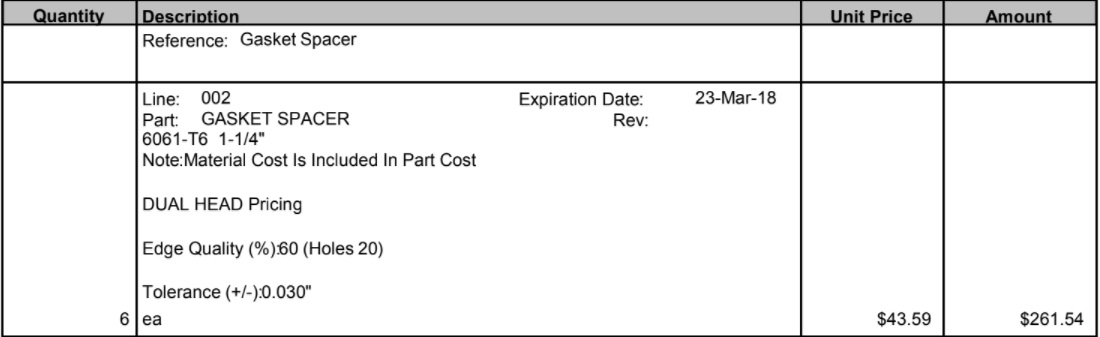

I'm getting a spacer for myself not matter what, but it is 3x cheaper if I make six, cheaper still if I make 10. The risk is that the spacer won't be big enough for your manifold or carb setup. The other risk is that your hose won't flex enough to account for the extra 32mm. I've talked to someone about that, and the hose that I'm using has a decent amount of play (untested). So... If you feel like spending $50 on an experiment with no gauranteed outcome, please chime in. Keep in mind that you will also need to purchase longer studs, as well as a second gasket (~$8).

By comparison, the modified Korman t-stat housing is around $250.

Problem - Note this is with a redline 3pc manifold, same clearance issue as the Korman manifold:

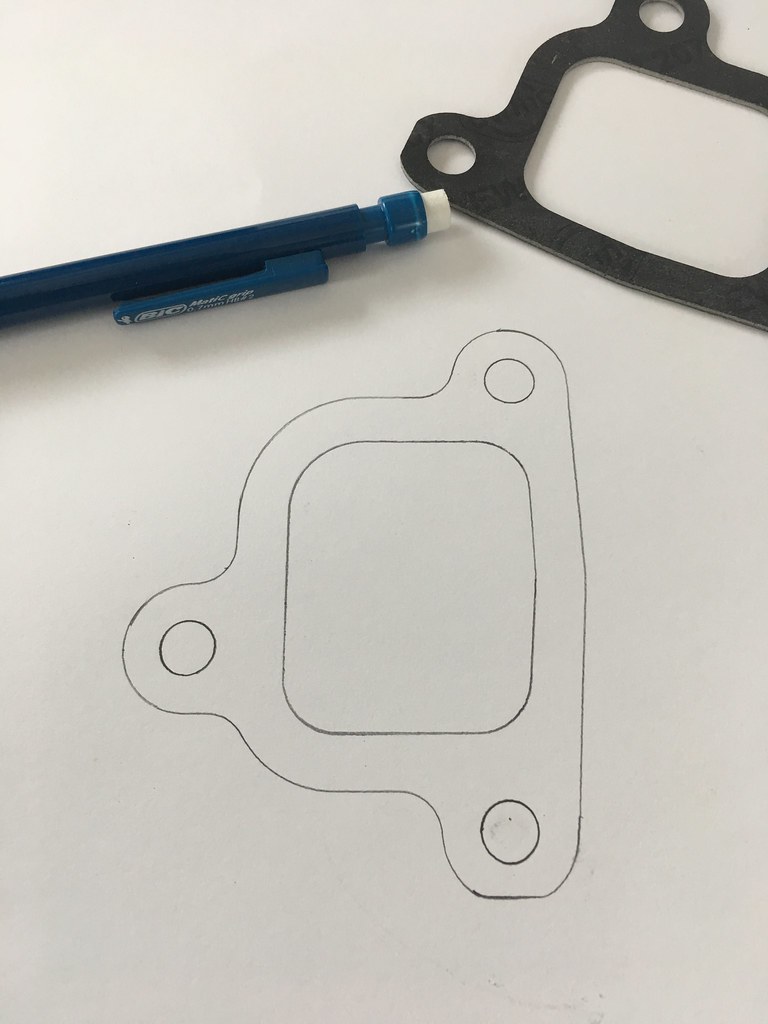

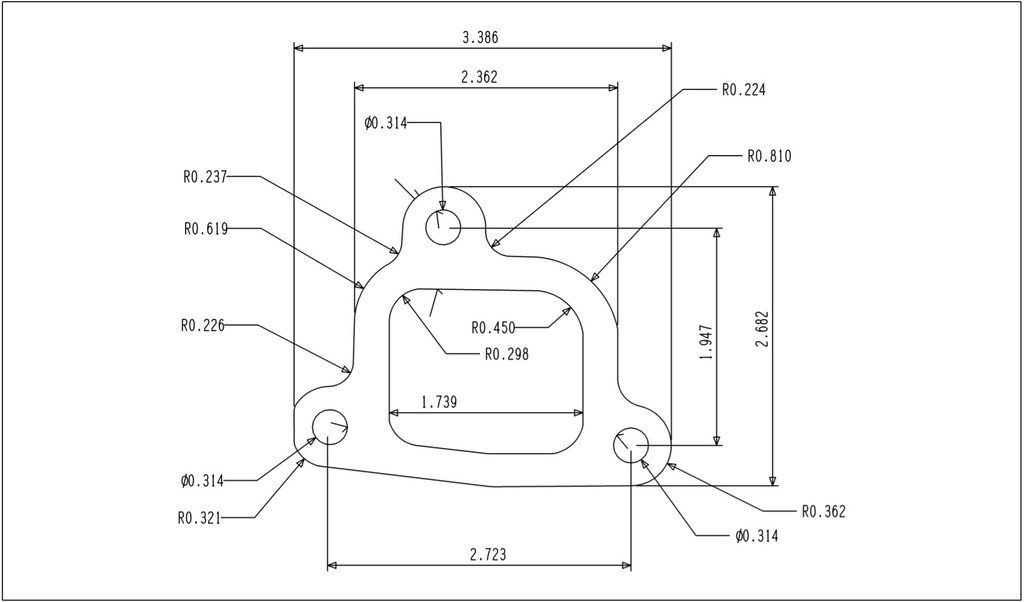

Tracing the gasket:

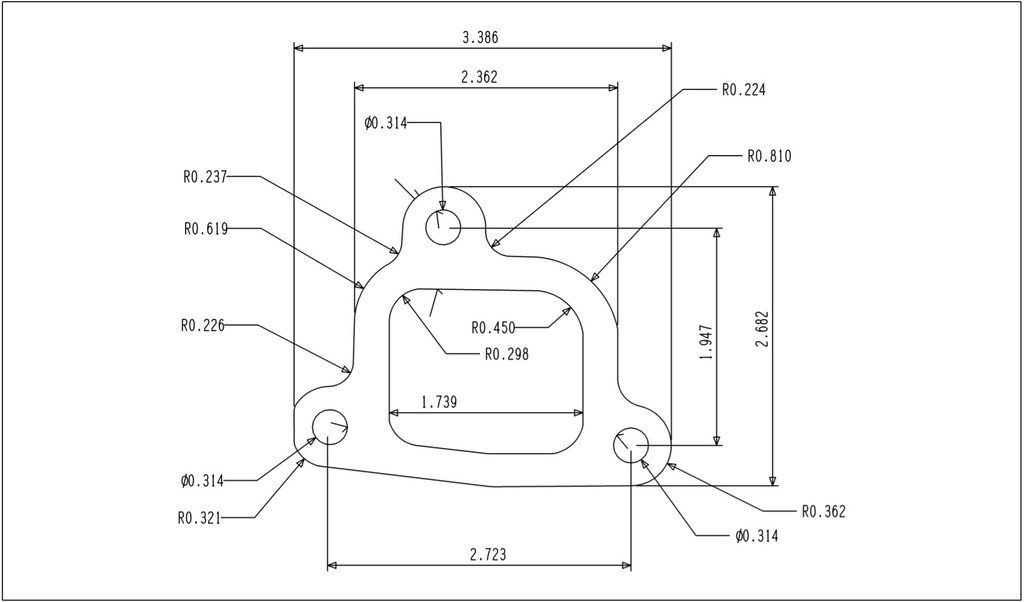

The waterjet company split the difference on the trace. The lead was .7mm on the pencil, and the t-stat flange has quite a bit of plate anyway. I told the guy that it's for water and not air, and I'm not terribly concerned about tolerances. He is going to do a test cut on MDF and compare against my gasket and flange..

The late model flange I'm using - $69 at BMW - this is the flange I used to test the 32mm's required.

Keeping me honest:

I'm making myself a 6061 water jet cut aluminum spacer for my t-stat housing. I arrived at a 32mm spacer that allows my housing to clear the adjuster on my type 152 DCOE 40's. The end product may be within a mm or so of this, as I have some flexibility.

I'm getting a spacer for myself not matter what, but it is 3x cheaper if I make six, cheaper still if I make 10. The risk is that the spacer won't be big enough for your manifold or carb setup. The other risk is that your hose won't flex enough to account for the extra 32mm. I've talked to someone about that, and the hose that I'm using has a decent amount of play (untested). So... If you feel like spending $50 on an experiment with no gauranteed outcome, please chime in. Keep in mind that you will also need to purchase longer studs, as well as a second gasket (~$8).

By comparison, the modified Korman t-stat housing is around $250.

Problem - Note this is with a redline 3pc manifold, same clearance issue as the Korman manifold:

Tracing the gasket:

The waterjet company split the difference on the trace. The lead was .7mm on the pencil, and the t-stat flange has quite a bit of plate anyway. I told the guy that it's for water and not air, and I'm not terribly concerned about tolerances. He is going to do a test cut on MDF and compare against my gasket and flange..

The late model flange I'm using - $69 at BMW - this is the flange I used to test the 32mm's required.

Keeping me honest:

Last edited: