so after this happened

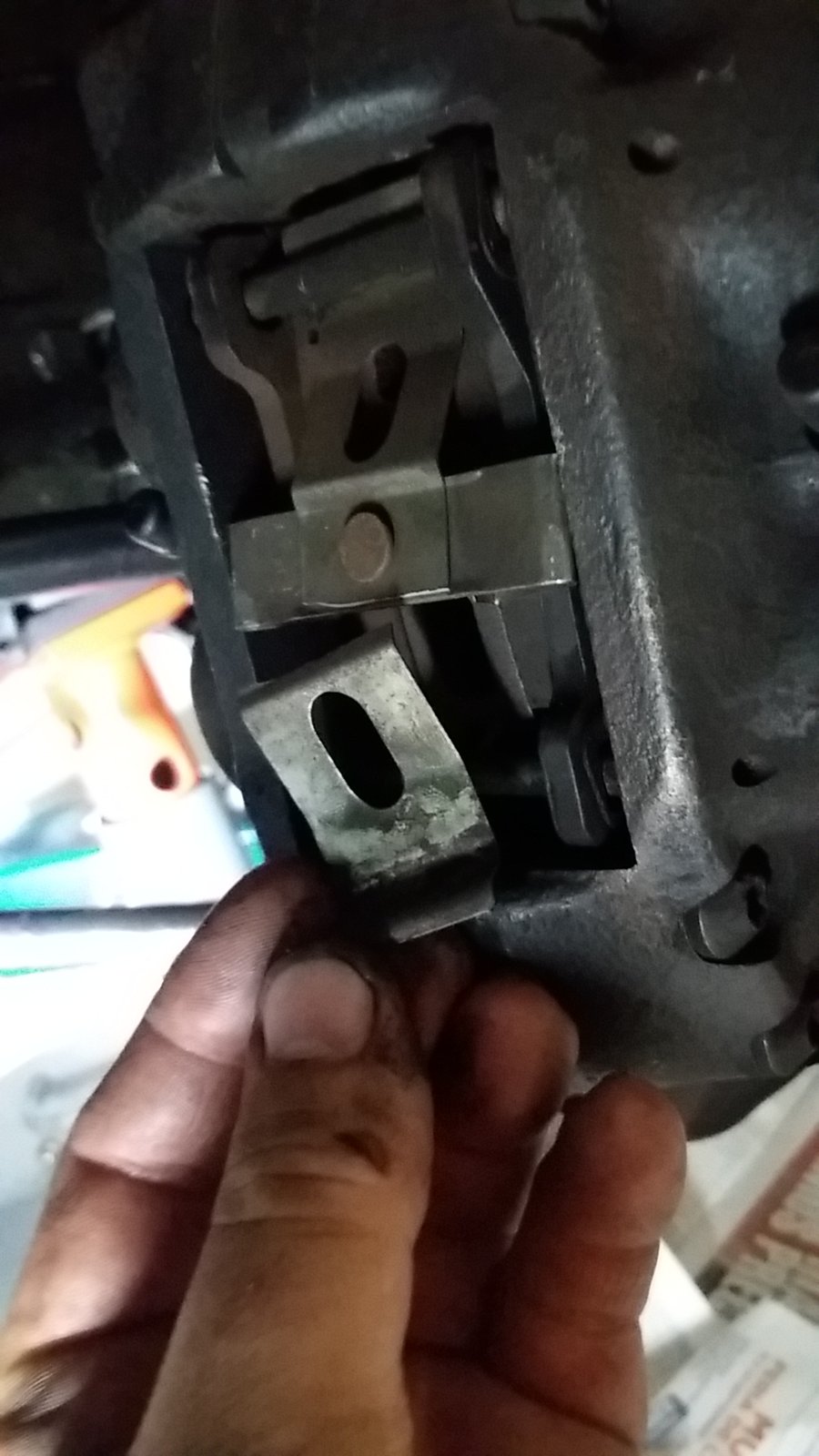

i have decided to take a deeper look on the front axle system,...

i have decided to take a deeper look on the front axle system,...

When I got my car the fronts were at 20 and rears at 18. So I put new ones in the front and left the rears alone.

If you're at 17, I would definitely change them. They are not that expensive and since you have it all apart it is really easy to do at this point.

I was also surprised by that. I am wondering if maybe the 21 mm spec is for a different year than yours…