once caliper is fixed i fix the flared nut with the wrench

next step, pads

next step, pads

Thanks for the write up. Interesting to see the internals of the front hub. I haven't tackled those yet.lk

Really enjoying the write up, great work

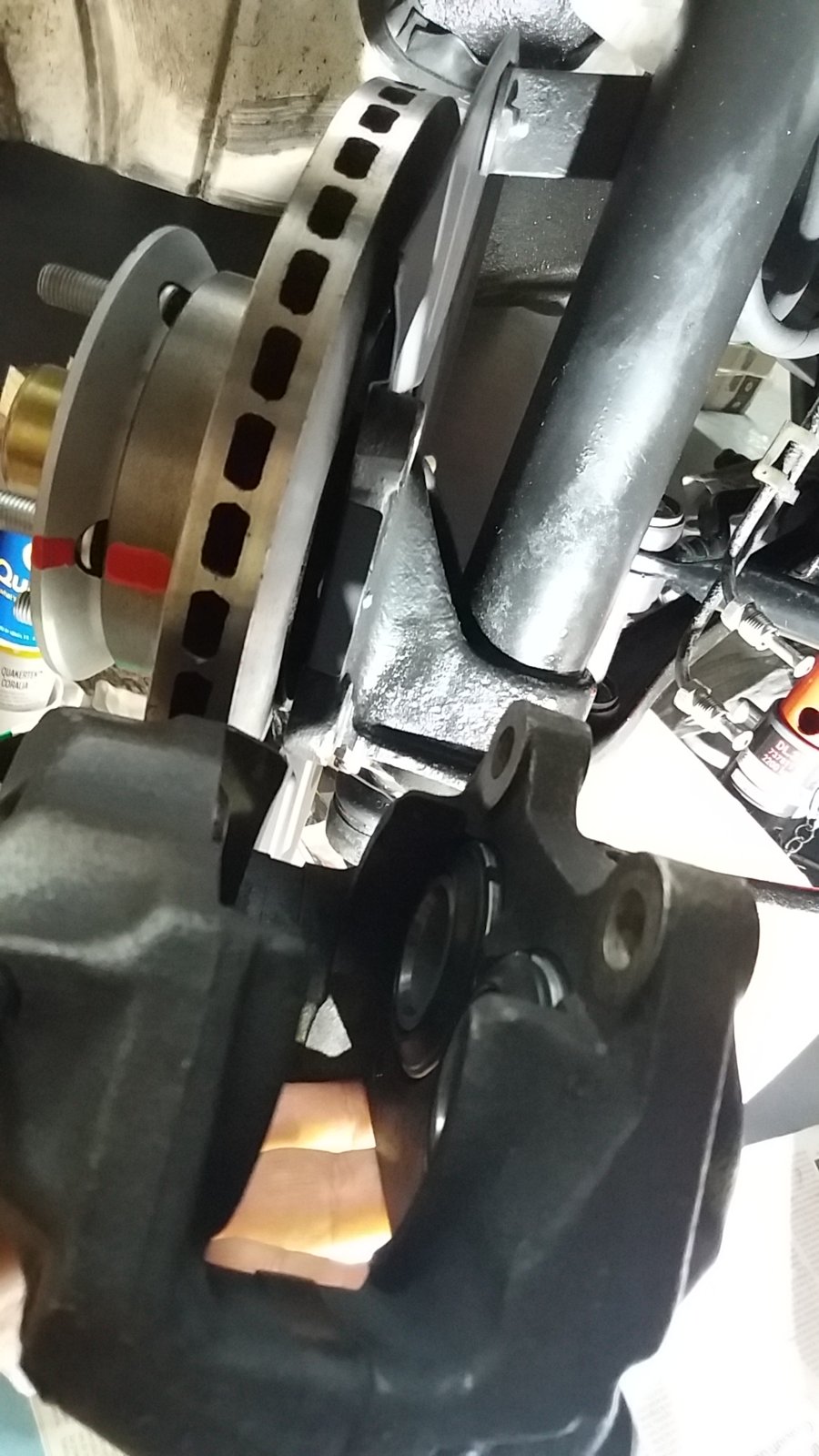

What's this one a piccie of?

Drew is inquiring into your brake pad separator tool.

It's a tool to increase the distance between the brake pads by pushing back (in) the brake pistons. As the pads are worn, they sit closer together. you can't just slide in the ticker new pads, there is no room for them. When replacing pads, the pistons need to be repositioned to allow inserting thicker new pads.

Now DeQ is very well assorted in the tools department. If your not (like me), a piece of solid oak, simple crowbar or thick screwdriver will do the same. Just remember to push the pistons back using the old brake pads as supporting surface for your screwdriver. Don't push the piston directly. try to push the middle of the pad, directly on top of the piston to avoid skewing the piston.

DeQ: how did you get the pistons out? Was it difficult?