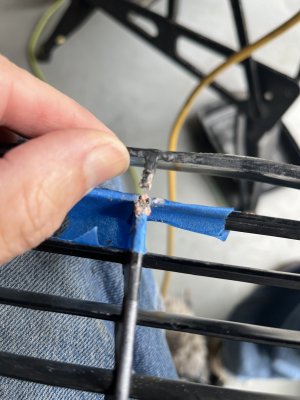

I am restoring my front grill and am trying to epoxy one of the broken grill pieces and cannot find anything strong enough to hold it. I have tried JB weld, two times and also Bondo. Any ideas of how to epoxy this piece together?

You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Front Grill Glue/Epoxy

- Thread starter Wobdog

- Start date

I would think a 2 part epoxy designed for plastic would be just as strong as the grill, providing the surfaces are prepped correctly.

Is the grill seeing a lot of tension or twist when installed? That might be leading you astray.

Is the grill seeing a lot of tension or twist when installed? That might be leading you astray.

I suspect that plastic welding would work well for this type of repair.

Hello, I have extra one if you want it tell me how much you want to pay or exchange with parts if you have any extra parts.I am restoring my front grill and am trying to epoxy one of the broken grill pieces and cannot find anything strong enough to hold it. I have tried JB weld, two times and also Bondo. Any ideas of how to epoxy this piece together?

thank you

Plastic welding would work, it is after all an injection moulded plastic part. I'm not sure what type of plastic it is, I'm guessing it is PC/ABS, but is is essential to know before trying to weld it. It has to be welded with similar material in order to be succesfull. It would likely involve outsourcing. And then cost will play a factor - for that reason I'd likely go DIY myself.

I see the part is really thin, but for a DIY approach I would try if you could drill/ mill/cut a 1 mm hole in it from the outer edge of the part, so that you can stick a 1 mm stainless metal rod in, perpendicular to the broken surface. This basically locates the parts, and then the glue has less mechanical load to take.

If the thickness is not enough to drill a hole, you may opt to sand 2 cavities, about half of the thickness of the plastic, on one side or the back. This the creates space for a flat plate of stainless steel to be glued in.

These solutions basically create 10 or 20 times the surface area of the broken surface area; thus 10-20 * stronger.

On the other hand, i see that the outer circumference is also deformed. heating it up and letting it cool down while sandwiched to something straight may work.

If it doesn't work out, then I'd probably call it quits and send Candia4441 a message

I see the part is really thin, but for a DIY approach I would try if you could drill/ mill/cut a 1 mm hole in it from the outer edge of the part, so that you can stick a 1 mm stainless metal rod in, perpendicular to the broken surface. This basically locates the parts, and then the glue has less mechanical load to take.

If the thickness is not enough to drill a hole, you may opt to sand 2 cavities, about half of the thickness of the plastic, on one side or the back. This the creates space for a flat plate of stainless steel to be glued in.

These solutions basically create 10 or 20 times the surface area of the broken surface area; thus 10-20 * stronger.

On the other hand, i see that the outer circumference is also deformed. heating it up and letting it cool down while sandwiched to something straight may work.

If it doesn't work out, then I'd probably call it quits and send Candia4441 a message

Last edited: