I doubt there will be much interest in this, given that there isn't really any reason to deviate from the stock torsion bar setup for most owners but I'll post just in case since the end result is very clean and cheap.

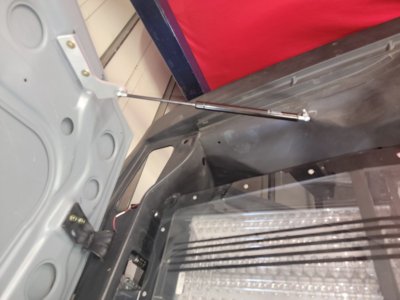

I couldn't use the torsion bar because it would interfere with my EV conversion battery box. The solution uses two 17" 40 pound gas struts. Part number 4138T78 at McMaster Carr https://www.mcmaster.com/catalog/128/1399 and some custom brackets. Price $25.54 each

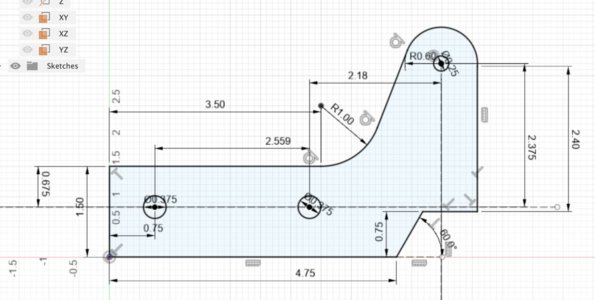

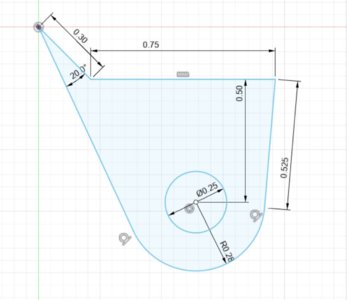

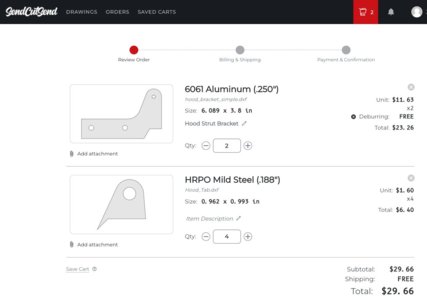

The front brackets bolt to the hood using the stock torsion bar mounting locations. In the back, you need to have a tab attached (welded) to the inner fender apron. I designed the brackets and tabs in Fusion 360 and had them cut by sendcutsend.com. I used 0.25" thick 6061 aluminum for the front and 0.188" thick HRPO mild steel for the tabs. Cost for cutting two brackets and 4 tabs (two extra just in case) just barely met their minimum order size of $29. I can't say enough good things about sendcutsend. They are very responsive, have quick turn around (it took 5 days for my parts to arrive), and their work is great. Having a service like theirs really opens up new possibilities.

You can have sendcutsend thread the M8 holes also but I did it myself since it isn't difficult. After that, just thread the strut ends in, bolt the front bracket to the hood, and see where the tab naturally meets the fender apron. Mark and weld. Obviously, if you have the sound deadening material in place you'll have to either remove it or open up a hole around the tab location. the struts do not interfere with any items under the hood. I removed the stock hood brace brackets from the apron but that's only because my car is already so modified it hardly matters if I "ruin" it a bit more.

The motion path of the bracket acts to hold the hood in the closed position and then rotates around at a few inches up, and assists in opening and holding the hood up. My hood is steel and the force is perfect -- no risk of bending the hood. If you have an aluminum hood you should probably use the 20 pound struts instead. Or just use your CSL stick and ignore all this.

If you're interested, just PM me and I'll send the DXF drawing files.

I couldn't use the torsion bar because it would interfere with my EV conversion battery box. The solution uses two 17" 40 pound gas struts. Part number 4138T78 at McMaster Carr https://www.mcmaster.com/catalog/128/1399 and some custom brackets. Price $25.54 each

The front brackets bolt to the hood using the stock torsion bar mounting locations. In the back, you need to have a tab attached (welded) to the inner fender apron. I designed the brackets and tabs in Fusion 360 and had them cut by sendcutsend.com. I used 0.25" thick 6061 aluminum for the front and 0.188" thick HRPO mild steel for the tabs. Cost for cutting two brackets and 4 tabs (two extra just in case) just barely met their minimum order size of $29. I can't say enough good things about sendcutsend. They are very responsive, have quick turn around (it took 5 days for my parts to arrive), and their work is great. Having a service like theirs really opens up new possibilities.

You can have sendcutsend thread the M8 holes also but I did it myself since it isn't difficult. After that, just thread the strut ends in, bolt the front bracket to the hood, and see where the tab naturally meets the fender apron. Mark and weld. Obviously, if you have the sound deadening material in place you'll have to either remove it or open up a hole around the tab location. the struts do not interfere with any items under the hood. I removed the stock hood brace brackets from the apron but that's only because my car is already so modified it hardly matters if I "ruin" it a bit more.

The motion path of the bracket acts to hold the hood in the closed position and then rotates around at a few inches up, and assists in opening and holding the hood up. My hood is steel and the force is perfect -- no risk of bending the hood. If you have an aluminum hood you should probably use the 20 pound struts instead. Or just use your CSL stick and ignore all this.

If you're interested, just PM me and I'll send the DXF drawing files.

Attachments

-

hoodBracketCAD.jpg146.4 KB · Views: 288

hoodBracketCAD.jpg146.4 KB · Views: 288 -

hoodTabCAD.jpg58.5 KB · Views: 254

hoodTabCAD.jpg58.5 KB · Views: 254 -

sendCutSend.jpg58.3 KB · Views: 246

sendCutSend.jpg58.3 KB · Views: 246 -

hoodPartsthreaded.jpg252.9 KB · Views: 282

hoodPartsthreaded.jpg252.9 KB · Views: 282 -

hoodSupports1.jpg181.3 KB · Views: 308

hoodSupports1.jpg181.3 KB · Views: 308 -

hoodSupports2.jpg156.2 KB · Views: 307

hoodSupports2.jpg156.2 KB · Views: 307 -

hoodSupports3.jpg178.8 KB · Views: 303

hoodSupports3.jpg178.8 KB · Views: 303 -

sendCutSendParts.jpg371.1 KB · Views: 330

sendCutSendParts.jpg371.1 KB · Views: 330