ScottAndrews

Well-Known Member

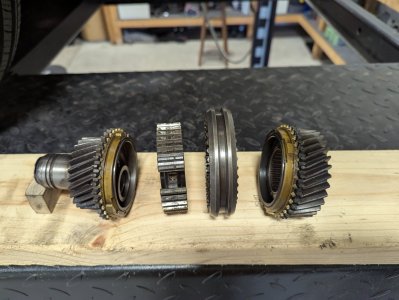

There is another thread asking about noise in the Getrag 265. I was curious about exactly how that trans worked. There were no good diagrams, so, decided to make one. This is based of a sectional view posted some time ago by @Devinder. I added the colors to highlight the various parts.

Here is the transmission in Neutral:

The input shaft on the left is light pink. The output shaft is purple./blue. The bearings are light blue. Some are rollers, so they are hard to see. The lay-shaft is orange, the shift clutches and syncros are maroon, and the gears are various colors. The gear faces that engage the lay shaft are shown in reddish orange.

The input shaft is connected by its gear directly to the lay shaft. So the lay shaft always turns when the input shaft is turning, and all of the colored gears are also turning, because they re meshed with the lay-shaft. This is what is known as a constant mesh gearbox, because the driving gears do not actually ever not mesh. This means that all of the colored gears are spinning all the time at different rates when the input shaft is turning (note all of them are separated from the output shaft by roller bearings (light blue), and this is why this whole thing works. Shifting is a process of selectively connecting the gears with the output shaft.

Here is the trans in 1st gear. the aft shift fork has moved the aft dog clutch to the left (yellow arrows). This connects the 1st gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the first gear.

Here is the trans in 2nd gear. The middle shift fork has moved the middle dog clutch to the right (yellow arrows). This connects the 2nd gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 2nd gear.

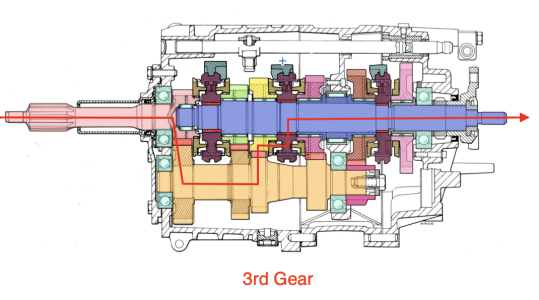

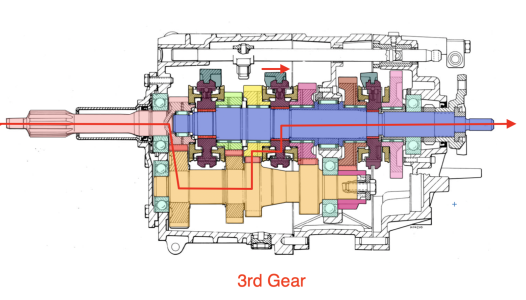

Here is the trans in 3rd gear. The middle shift fork has moved the middle dog clutch to the left (yellow arrows). This connects the 3rd gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 3rd gear.

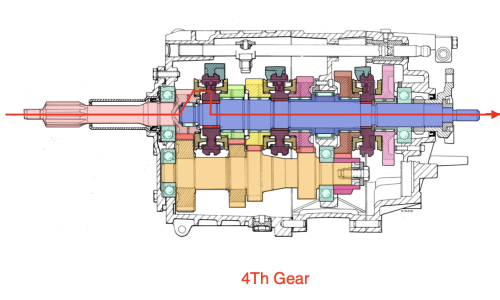

Here is the trans in 4th gear. The forward shift fork has moved the forward dog clutch to the left (yellow arrows). This connects the input shaft to the output shaft to create a 1:1 ratio. Thus the torque comes in the input shaft and goes directly to the output shaft. In this gear the lay-shaft is turning, but it is carrying no load, because none of the gears it engages are connected to the output shaft.

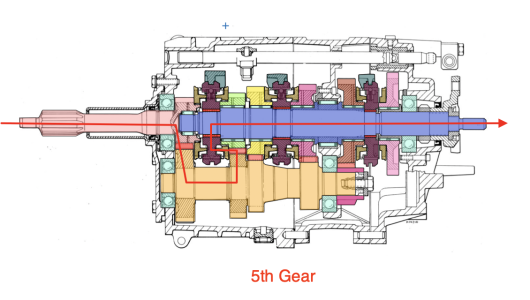

Here is the trans in 5th gear. The forward shift fork has moved the forward dog clutch aft (yellow arrows). This connects the 5th gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 5th gear.

And lastly, here is the trans in reverse. The aft shift fork has moved the aft dog clutch to the right (yellow arrows). This connects the reverse gear to the output shaft. There is a secondary lay shaft (not shown in the diagram) that connects the lay shaft to the reverse gear, and thus the torque comes in the input shaft, goes to the lay-shaft, goes to another lay shaft (thereby reversing direction), and then gets connected to the output shaft via the reverse gear.

I think this is all correct, but if I have misunderstood then please let me know,.

Here is the transmission in Neutral:

The input shaft on the left is light pink. The output shaft is purple./blue. The bearings are light blue. Some are rollers, so they are hard to see. The lay-shaft is orange, the shift clutches and syncros are maroon, and the gears are various colors. The gear faces that engage the lay shaft are shown in reddish orange.

The input shaft is connected by its gear directly to the lay shaft. So the lay shaft always turns when the input shaft is turning, and all of the colored gears are also turning, because they re meshed with the lay-shaft. This is what is known as a constant mesh gearbox, because the driving gears do not actually ever not mesh. This means that all of the colored gears are spinning all the time at different rates when the input shaft is turning (note all of them are separated from the output shaft by roller bearings (light blue), and this is why this whole thing works. Shifting is a process of selectively connecting the gears with the output shaft.

Here is the trans in 1st gear. the aft shift fork has moved the aft dog clutch to the left (yellow arrows). This connects the 1st gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the first gear.

Here is the trans in 2nd gear. The middle shift fork has moved the middle dog clutch to the right (yellow arrows). This connects the 2nd gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 2nd gear.

Here is the trans in 3rd gear. The middle shift fork has moved the middle dog clutch to the left (yellow arrows). This connects the 3rd gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 3rd gear.

Here is the trans in 4th gear. The forward shift fork has moved the forward dog clutch to the left (yellow arrows). This connects the input shaft to the output shaft to create a 1:1 ratio. Thus the torque comes in the input shaft and goes directly to the output shaft. In this gear the lay-shaft is turning, but it is carrying no load, because none of the gears it engages are connected to the output shaft.

Here is the trans in 5th gear. The forward shift fork has moved the forward dog clutch aft (yellow arrows). This connects the 5th gear to the output shaft, and thus the torque comes in the input shaft, goes to the lay-shaft, and then gets to the output shaft via the 5th gear.

And lastly, here is the trans in reverse. The aft shift fork has moved the aft dog clutch to the right (yellow arrows). This connects the reverse gear to the output shaft. There is a secondary lay shaft (not shown in the diagram) that connects the lay shaft to the reverse gear, and thus the torque comes in the input shaft, goes to the lay-shaft, goes to another lay shaft (thereby reversing direction), and then gets connected to the output shaft via the reverse gear.

I think this is all correct, but if I have misunderstood then please let me know,.